In 1996, Sanyo Chemical established the management policy on responsible care (RC). It also joined the Japan Responsible Care Council (currently the RC Committee of the Japan Chemical Industry Association) and started RC activities. In FY2000, Sanyo Chemical launched the Environmental Action Plan, which specified priority action items and target values. The scope was expanded to subsidiaries and affiliates in Japan in FY2004 and to overseas subsidiaries and affiliates in FY2007, to promote environmental management on a Group basis.

Policy

Our company mission states, “We will strive for perfection in safety and harmony with the environment, which is the first required mission in society.” Our Code of Corporate Ethics states, “We shall proactively take initiatives to conserve the environment and prevent accidents and disasters as crucial requirements for the sustainability and activity of our business.”

The CSR Guidelines specify reduction of environmental impact in Item 3, contribution to the environment and the improvement of personal lives through product development in Item 4, and sustainable purchasing in Item 5 to promote specific activities.

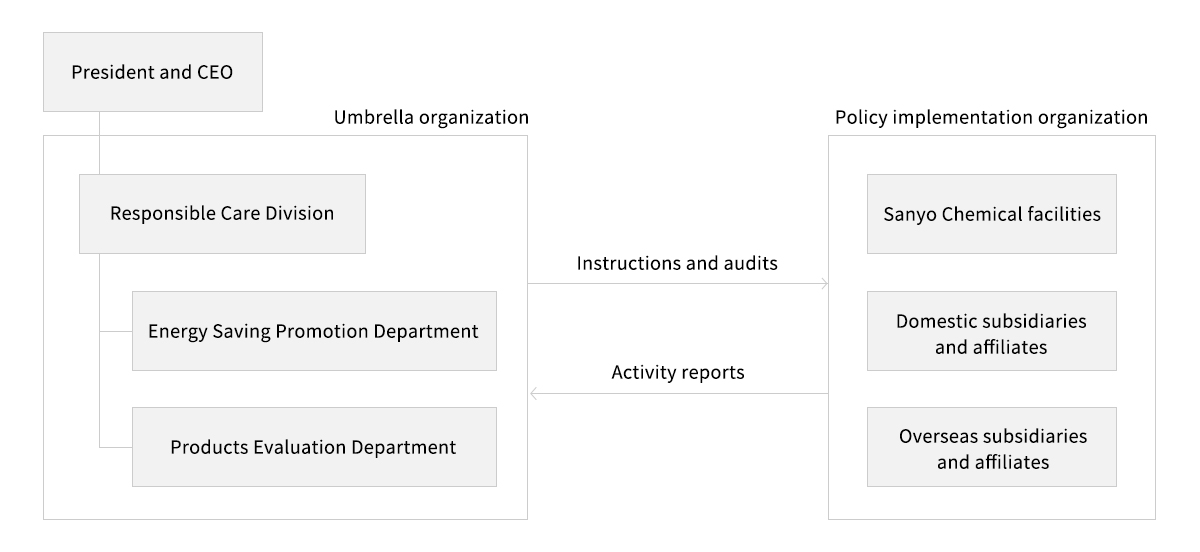

Management system

*Horizontally scrollable

In January 2023, the Responsible Care Division was reorganized. Overall environmental conservation activities other than energy conservation and global warming measures, which had been undertaken by the Environmental and Safety Administration Dept., were transferred to the Energy Saving Promotion Dept., which had specialized in energy conservation and global warming measures. Accordingly, the Energy Conservation Promotion Dept. assumed the responsibility for supervising overall “environmental conservation” activities among the five RC activities.

The “chemicals/product safety” activities and part of “logistics safety” will continue to be covered by the Products Evaluation Dept. “Labor safety and health” and “safety/accident prevention” were separated from the Responsible Care Division and transferred to the Safety Promotion Department, which was newly established as a department under the direct control of the President and CEO.

Concerning the environmental management system (ISO 14001), which we had used as one of our RC promotion tools, we discontinued the certifications for domestic factories based on our judgment that we are able to adequately operate the system on our own. The certifications of overseas facilities will continue. We will continue the certifications of both domestic and overseas facilities for the quality management system (ISO 9001).

We will also continue the RC (safety, health, environment, and security) audits that we conduct once a year by visiting the sites of listed companies and laboratories in Japan.

What is Responsible Care?

Responsible Care is a voluntary activity in which businesses that manufacture or handle chemical substances ensure the environment, health, and safety throughout the entire process from development, manufacture, distribution, use, and final consumption to disposal of chemical substances based on the principle of self-responsibility, i.e., promoting the five activities of environmental conservation, occupational health and safety, safety and disaster prevention, chemical and product safety, and distribution safety, promoting information disclosure and dialogue with society.

Environmental action plan 21-24(FY2021 to FY2024)

Initially, GHG emissions reduction and energy conservation were set out as activity themes for the Environmental Action Plan 21-24. To accelerate activities toward carbon neutrality, the two themes were transferred to the CSR Promotion Management Committee in FY2022. The themes of water conservation, reduction of waste generation, and reduction of VOCs will continue to be pursued under the action plan.

Scope : All facilities of Sanyo Chemical, all domestic SUBSIDIARIES & AFFILIATES and overseas facilities which have production bases*1

- Sanyo Chemical Texas Industries, LLC, Sanyo Kasei (Thailand) Ltd., Sanyo Kasei (Nantong) Co., Ltd., San-Dia Polymers (Nantong) Co., Ltd., SDP GLOBAL (MALAYSIA) SDN. BHD.,

*Horizontally scrollable

| Theme | FY2019 result (base year) |

FY2024 target | Note | |

|---|---|---|---|---|

| Target | Reduction rate compared with base year |

|||

| Water saving | 4,354 | 4,136 or less | 5% or more | Reduction of 1% or more per year |

Water usage (thousand m3) |

||||

| Waste generation control | 5.9 | 3.6 or less | 39% or more | - |

Waste generated (10,000 tons) |

||||

| VOC*2 emissions reduction | 112 Domestic:89 Overseas:22 |

90 or less Domestic:80 or less Overseas:10 or less |

19.7% or more | - |

VOC emissions volume (tons) |

||||

- Total emission of substances subject to former and revised PRTR Laws, and substances specified by the Japan Chemical Industry Association

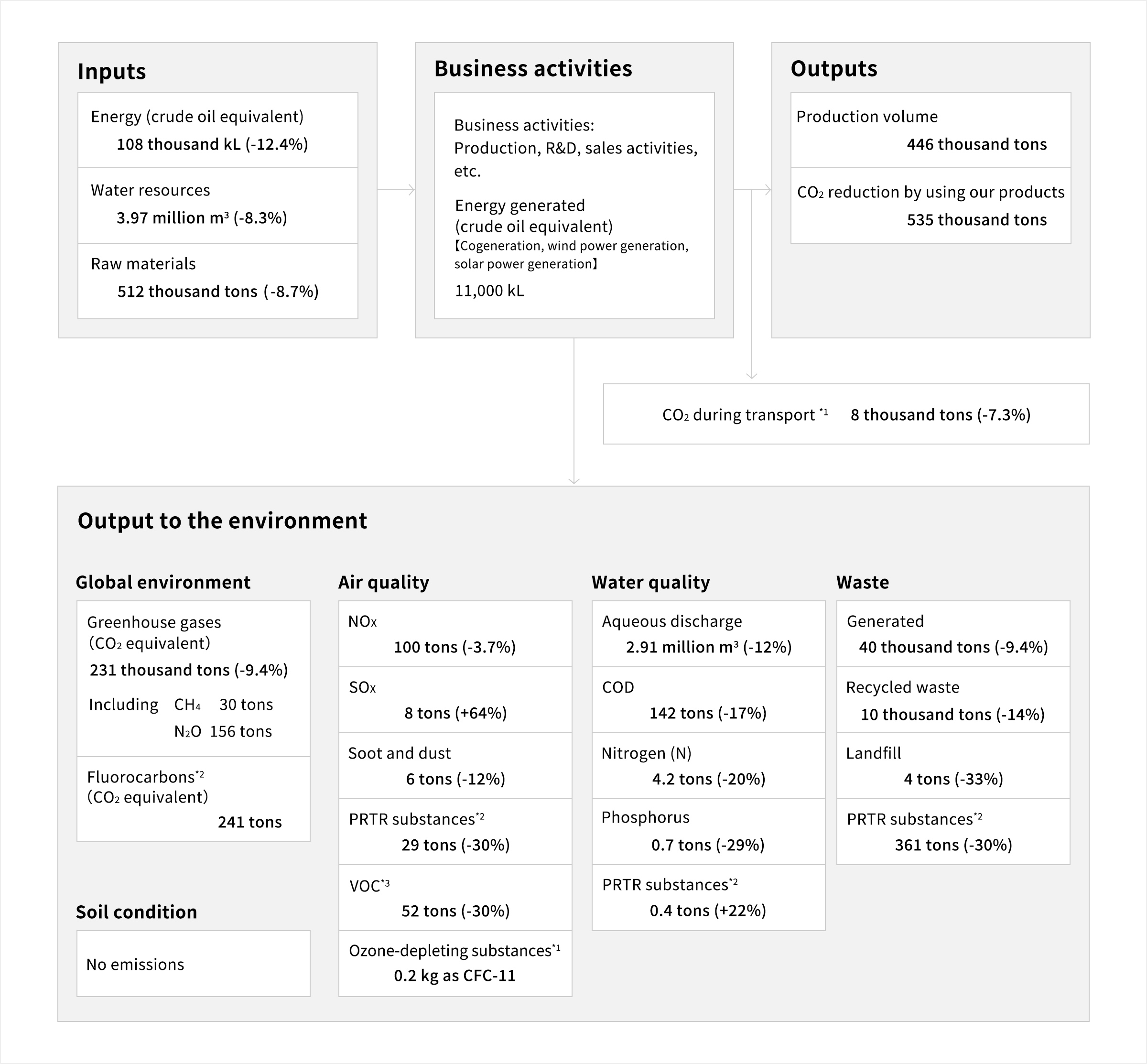

Material flow in FY2022

*Horizontally scrollable

The values shown above are the values for consolidated results for all domestic and overseas facilities.

- Domestic total

- Total of SCI (all facilities in Sanyo Chemical Industries, Ltd.), SDP Global Co., Ltd., and SAN NOPCO LIMITED

- Total of Domestic (SCI plus domestic affiliates/subsidiaries), Sanyo Kasei (Thailand) Ltd. Sanyo Kasei (Nantong) Co., Ltd. San-Dia Polymers (Nantong) Co., Ltd. and SDP GLOBAL (MALAYSIA) SDN. BHD.

Environmental management indicators

Environmental accounting (April 1, 2022 to March 31, 2023)

Scope of summarization:Seven domestic and five overseas subsidiaries and affiliates with production facilities accounting data have been consolidated and compiled in accordance with the Environmental Accounting Guidelines 2005 (Ministry of the Environment). SKT, however, uses a fiscal year from January 1, 2022 to December 31, 2022.

Environmental Protection Costs

[Business activities by category]

(million yen)

| Classification | Investment*1 | Expense*2 | |

|---|---|---|---|

| Facility area costs | (1) Pollution prevention costs | 297 | 875 |

| (2) Global environment costs | 27 | 663 | |

| (3) Resource recycling costs | 1 | 1,898 | |

| Upstream/Downstream costs | 0 | 33 | |

| Administrative costs | 3 | 505 | |

| R&D costs | 0 | 730 | |

| Social activity costs | 0 | 138 | |

| Environmental remediation costs | 0 | 4 | |

| Total | 327 | 4,846 | |

- The investment amount is based on the acceptances during the corresponding period.

- The expense amount includes depreciation.

[Environmental conservation measures by category]

(million yen)

| Classification | Investment | Expense |

|---|---|---|

| (1) Costs related to global warming measures | 34 | 642 |

| (2) Costs related to ozone layer protection measures | 0 | 2 |

| (3) Costs related to air quality conservation measures | 224 | 408 |

| (4) Costs related to noise and vibration | 0 | 74 |

| (5) Costs related to environmental conservation measures for the aquatic, ground, and geologic environments | 62 | 456 |

| (6) Costs related to waste product and recycling measures | 1 | 1,906 |

| (7) Costs related to measures for reducing chemical risk and emissions | 0 | 259 |

| (8) Costs related to natural environmental conservation | 1 | 16 |

| (9) Other costs | 5 | 354 |

| Total | 327 | 4,116 |

- Expenses for research and development are not classified.

[Economic impact]

(unit: million yen)

*Horizontally scrollable

| Results | Reduced costs (million yen) | Main items | |

|---|---|---|---|

| Energy saving | 20 | Reduction in purchase of electricity and steam by using waste heat and cogeneration, etc. | |

| Resource saving | Waste reduction | 7 | Reduction in consumption of resources and generation of waste through process improvements |

| Raw material use reduction (yield improvement) | 82 | Increase in product yield and reduction in process chemicals | |

| Revenue from recycling | 70 | Income on sale of waste solvents, used containers, etc. | |

| Total | 179 | ||

- Including effects of measures that do not involve investment (e.g., improvement of the manufacturing processes)

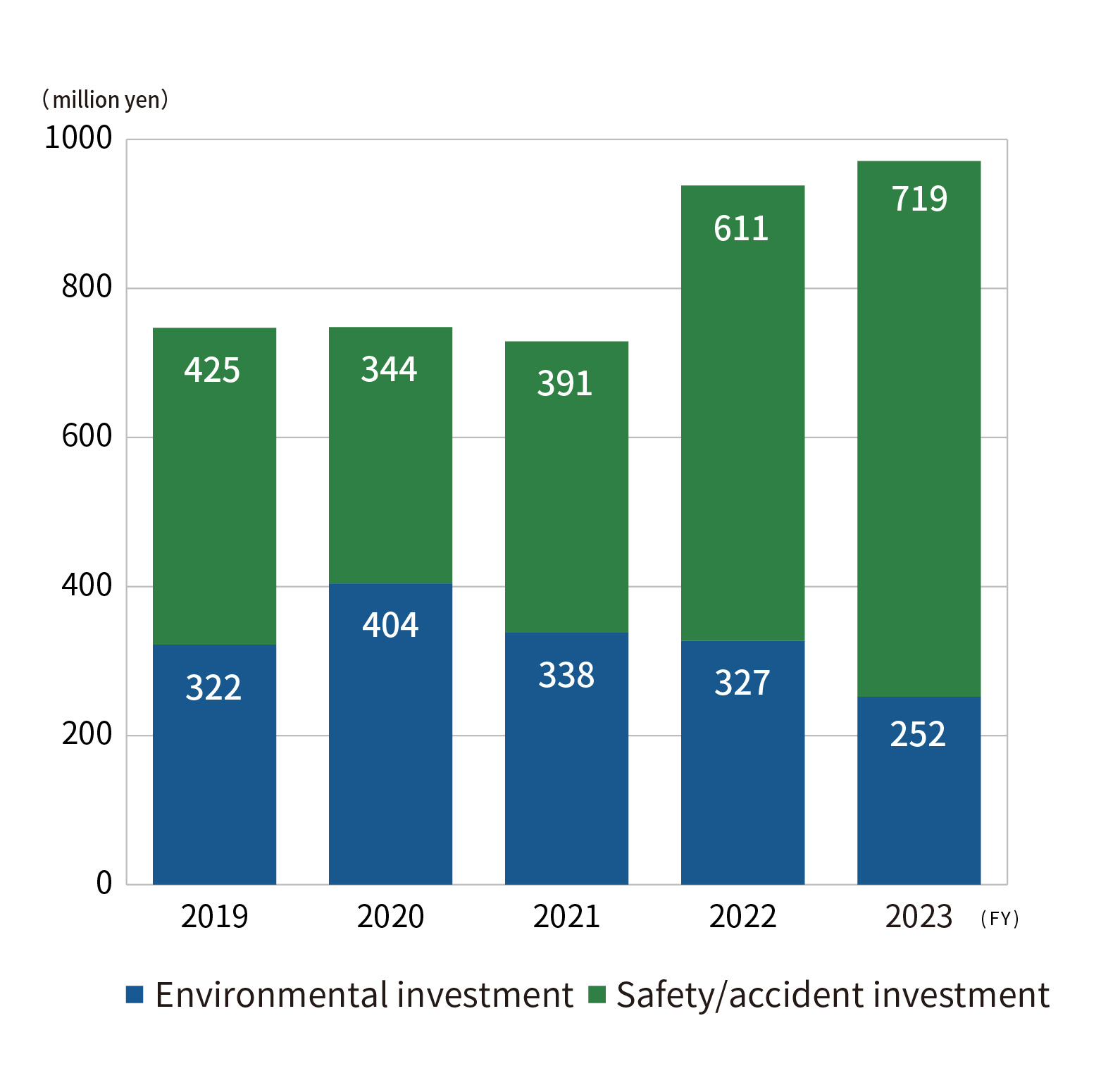

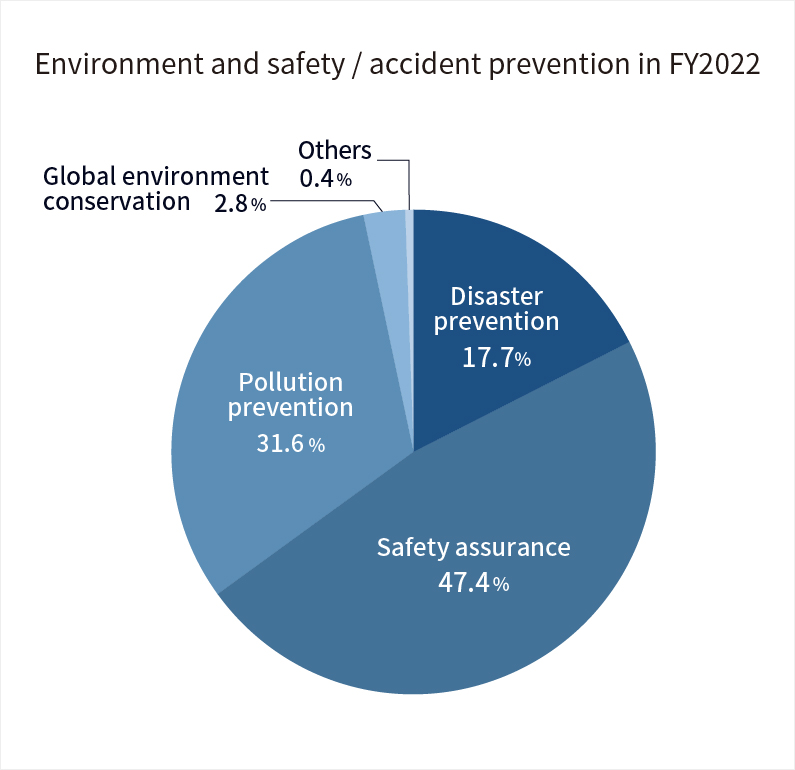

Environmental and safety/accident prevention investments

We are engaged in environmental conservation and safety assurance. We proactively invest not only in environmental measures, but also in safety and accident prevention, including industrial accidents, measures against earthquakes, and the 3Ds (Dirty, Dangerous, and Demanding jobs) improvements.

In FY2022, our environmental investments totaled 330 million yen, and the investments in safety/accident prevention was 610 million yen.

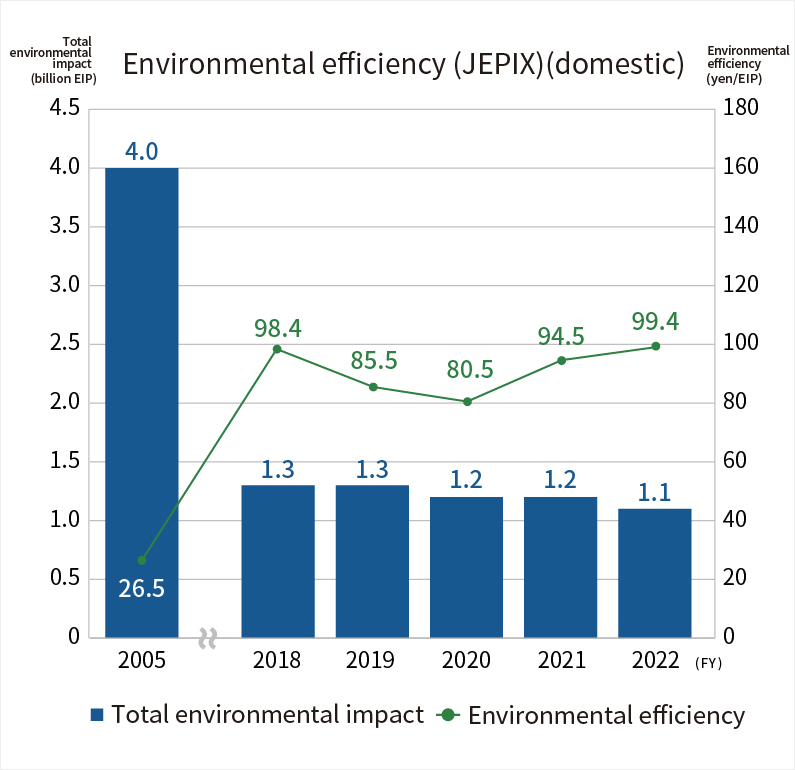

Environmental efficiency index JEPIX*

Our environmental efficiency has been greatly improved by reducing exhaust gas emissions of ethylene oxide, implemented in 2005, and propylene oxide, implemented in FY2012. Our environmental efficiency has been improving since FY2020.

- JEPIX (http://www.jepix.org) (Japanese only) Calculated using PEPIX Calculation Sheet Ver. 2

-

Japan Environmental Policy Priorities Index

The total environmental point (EIP) is multiplied by the weighted coefficient of each type of environmental impact such as GHG and hazardous air pollutants. Environmental efficiency is calculated by driving EIP by adjusted gross sales (JPY). The smaller the EIP, the better the environmental efficiency.