ACLUBE V-5130

Outline

Viscosity Index Improver for Multi-Grade Engine Oil, Exhibiting Viscosity Index Improvement and Shear Stability

Features

A viscosity index improver for engine oils which consists of a methacrylate copolymer and a refined mineral oil.

Suitable for preparation of engine oils for automobiles which needs high fuel efficiency because this product exhibits excellent viscosity index improvement for base oils.

Exhibits high shear stability as a viscosity index improver for engine oils for automobiles.

Related Videos

Comparison of kinematic viscosity measurement at 40℃ and flowability at low temperatures between ACLUBE-added oil and oil added by the other company's products.

Functions

- ・Lubricating/Leveling

- ・Viscosity Controlling

Applications

- ・Automobiles

- ・Lubricants

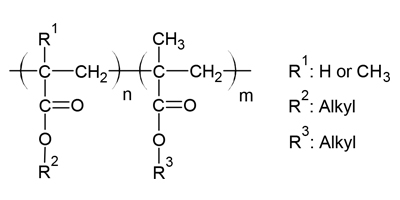

Composition

Methacrylate/Acrylate-based Polymethacrylate-type

Properties, and other information

| Principal Component | methacrylate copolymer and a refined mineral oil | Appearance | Straw colored liquid | Color(hazen, Gardner, etc) | Approx. 0.5(ASTM) |

| Kinematic viscosity(mm²/s)(temperature measurement) | 350(100℃) | Density(g/cm3 , ℃, etc) | 0.87(15℃) |

Precaution Against Mishandling

· Evenly dissolve this product in a base oil. If ACLUBE V-5130 is unevenly dissolved in the base oil, this product may not exhibit its expected viscosity index improvement.

· Before blending this product with a high-viscosity base oil (e.g., bright stock), low polarity base oil (e.g., highly refined mineral oil) or lubricating oil additives (e.g., a detergent or a dispersant) in large amounts, test that the blended oil is able to maintain its stability over a suitable period of time to ensure that there are no problems.

· Blend this product between 50 and 80 °C. If this product is heated above 80 °C, deterioration may occur.

Other Precautions

When storing this product in a tank, observe the following conditions to prevent quality deterioration.Maximum storage temperature: 50℃、Maximum storage period: 6 months

Before handling this product, refer to the current Safety Data Sheet for recommended protective equipment, and detailed precautionary and hazards information.If SDS is not listed on the homepage, please contact our sales representative.