Policy

Sanyo Chemical Group will work to bring about a circular economy and strive for social sustainability. Industrial waste such as waste oil, waste acids and alkalis, waste plastics, and scrap metal is generated in the process of manufacturing chemical products, but we are working to effectively utilize resources through the 3Rs (reduce, reuse, recycle). As an important issue for us, we will focus particularly on generating less waste (reduce) as that will lead to less CO2 emissions during incineration.

Targets and Results

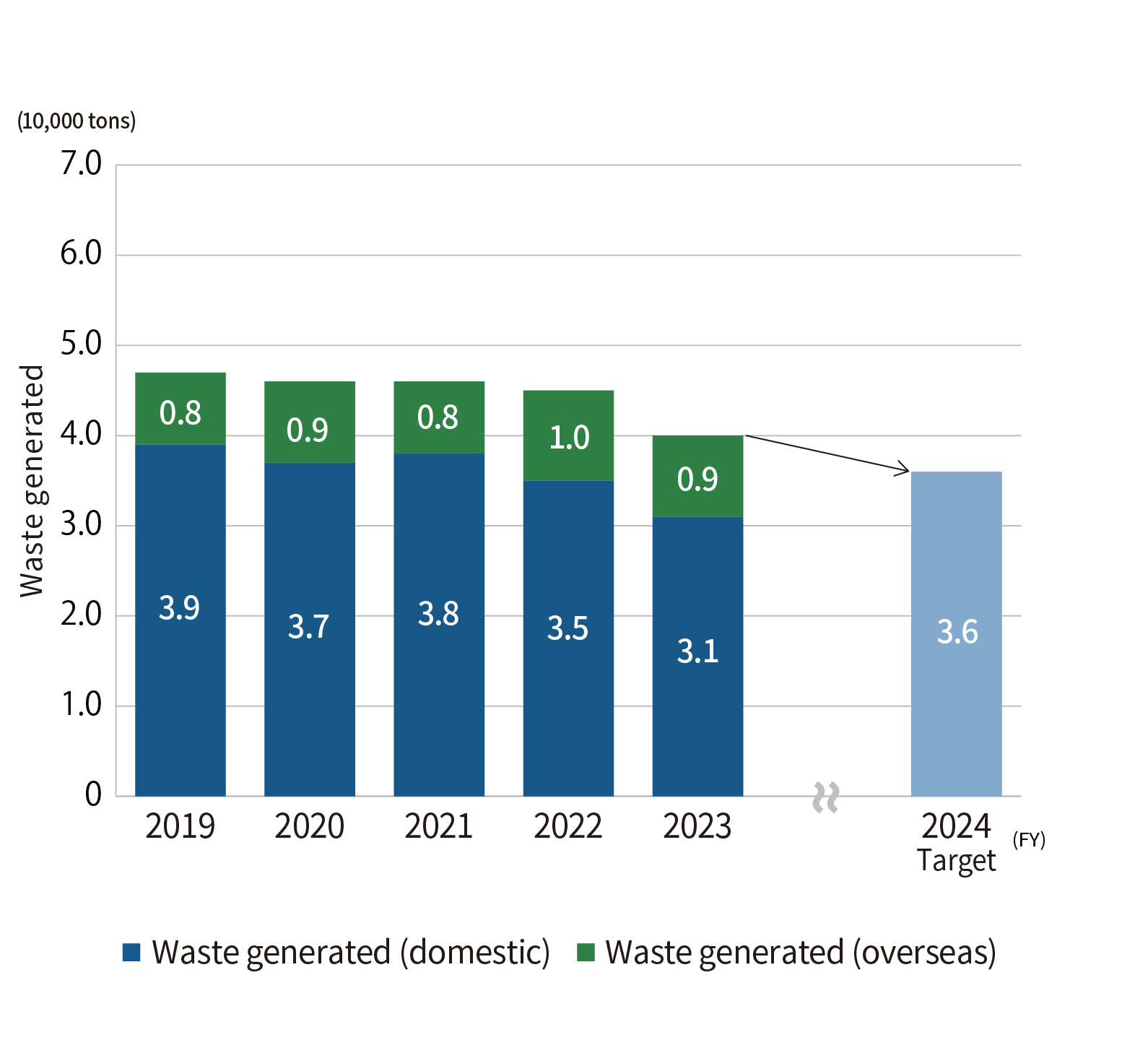

Waste Generated

The amount of waste generated in FY2024 was 32,000 tons, achieving the target of 36,000 tons or less set for the end of FY2024. We will continue working to reduce waste to reach our target of 31,000 tons or less by the end of FY2025.

We kept landfill disposal at 0.01% of waste generated. Twelve of all of our 13 facilities had zero landfill disposal.

Waste generated

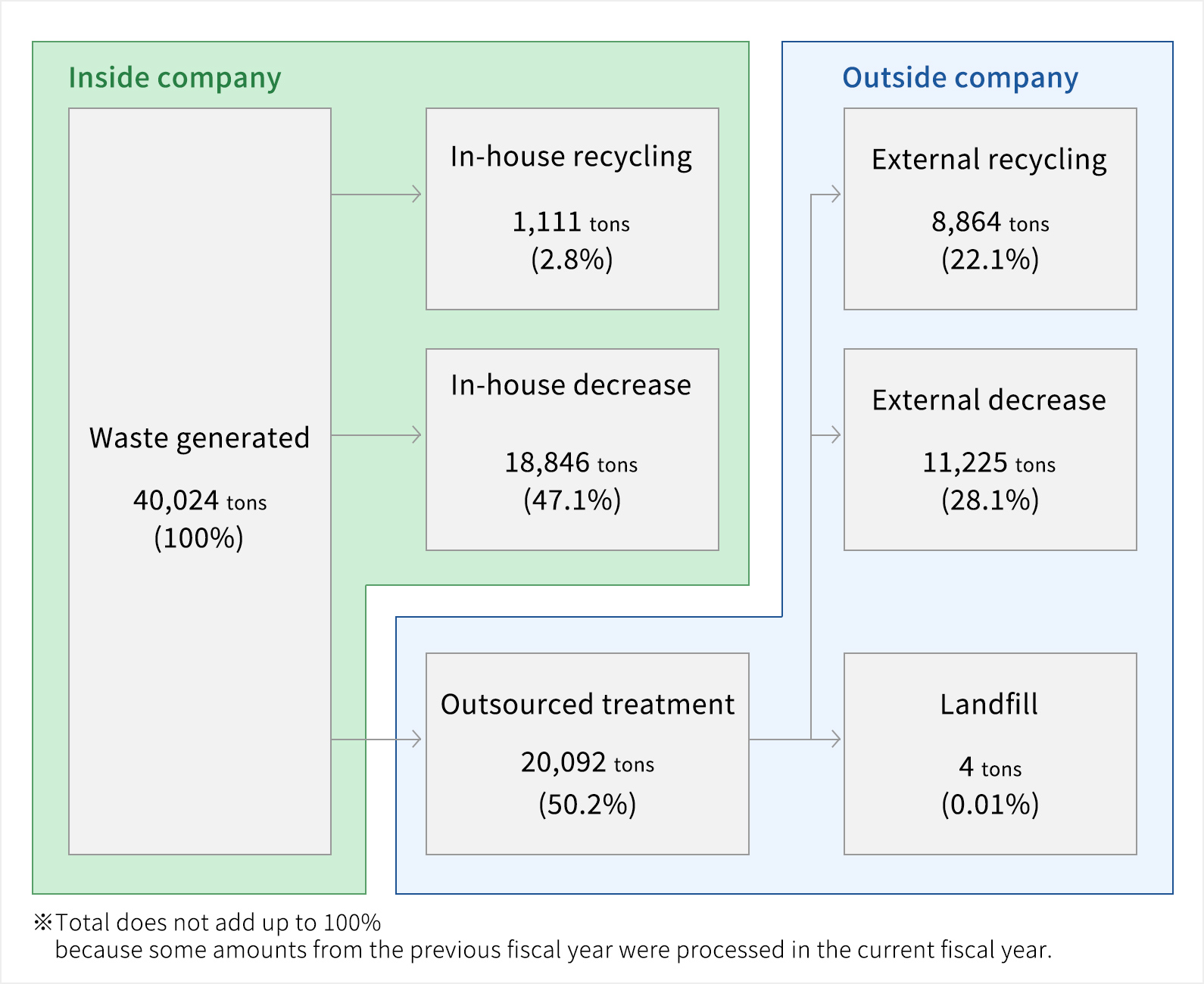

Material Flow of Waste

Sanyo Chemical Group generates large volumes of waste material that is a mixture of water and organic matter, such as cleaning water for equipment and products, and waste liquids generated during manufacturing processes. As this material is not suitable for recycling, 52.2% of the waste we generate is reduced in weight in-house through incineration and other methods, while 20.5% is reduced off-site.

In addition, 27.3% of our waste is recycled either in-house or off-site.

Material Flow of Waste (FY2024)

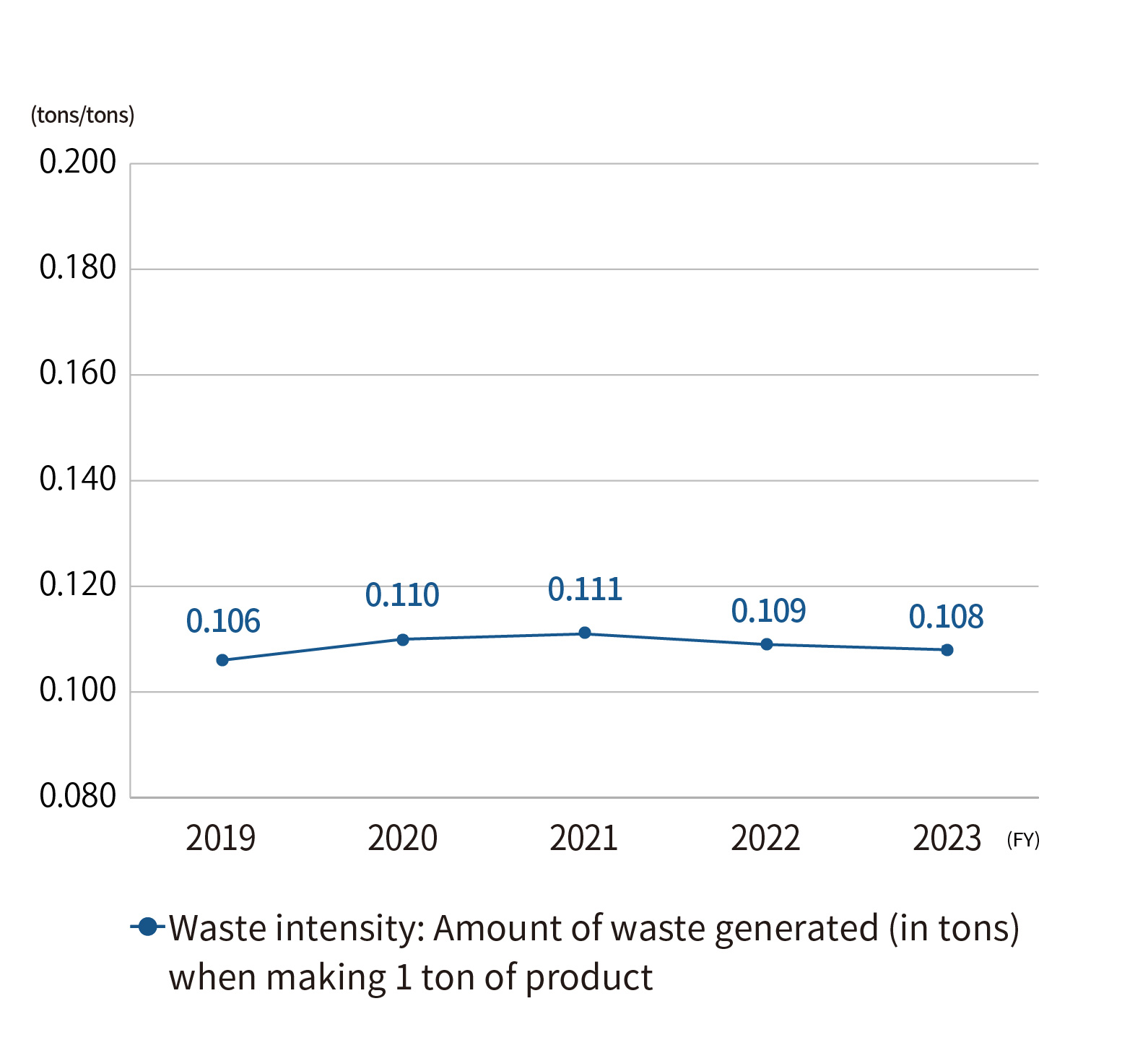

Reducing Waste Generation

Due to a new focus on prioritizing sales of high-value-added products in our management policy, our product mix has changed and waste generation intensity has decreased due to a reduction in the production of products that generate a large amount of waste. Waste generation per unit of production has further declined due to waste generation control measures such as optimizing (reducing) the amount of raw materials used, improving yields, and reviewing the frequency of and methods for cleaning equipment.

Trend of waste generation intensity (domestic)

Recycling

In FY2024, 2.9% of waste generated was recycled inside and 24.4% was recycled outside the Company.

(Specific examples)

- Solvents used for cleaning equipment are constantly reused inside the Company.

- Solvents and monomers that are recovered in the production process and that can be recycled are refined and reused.

- Metals, wood, paper, and other materials undergo material recycling outside the Company.

- Some waste plastics undergo material recycling outside the Company. Most undergo thermal recycling.

- Use recycled drums in some areas.

(Percentage of recycled drums purchased: FY2023: 29.6% FY2024: 29.8%)

Reduction and Recycling of Industrial Waste From Plastic Products

Our Company falls under the category of a high-volume waste producer (250 tons or more per year) as defined in the Act on Promotion of Resource Circulation for Plastics.

Although domestic affiliates are not classified as high-volume waste producers, they are working to reduce waste while sharing information with Sanyo Chemical.

Some of this waste is recycled into raw materials for roadbed materials and plastic products, and most of it are thermally recycled.

Targets and Results

(Unit: tons)

*Horizontally scrollable

| FY2021 Results |

FY2022 Results |

FY2023 Results |

FY2024 | FY2025 Target |

||

|---|---|---|---|---|---|---|

| Target | Results | |||||

| Waste generation (Sanyo Chemical) | 1,061 | 959 | 1,131 | 1,147 | 1,377 | 1,415 |

| Waste generation (domestic subsidiaries and affiliates*) | 48 | 52 | 33 | 34 | 42 | 41 |

| Total | 1,109 | 1,011 | 1,164 | 1,181 | 1,419 | 1,456 |

- SDP Global Co., Ltd.; San Chemical Co., Ltd.; SAN NOPCO LIMITED; and San-Petrochemicals Co., Ltd.