As a chemical company, the Sanyo Chemical Group handles many chemical substances in its business activities. Chemical manufacturers are required to endeavor to ensure environmental protection, safety, and health throughout the entire lifecycle, including product development, manufacture, logistics, and use/disposal of products sold, and to minimize the negative impact of chemical substances.

Policy

The chemical substances management regulations stipulate that “regarding chemical substances handled in business activities, we ensure proper management in compliance with relevant laws and regulations, etc. in and outside Japan by taking into account the impact on the global environment, ecosystem, and human health and social trends in Japan and the global community.” Management targets are all chemical substances contained in products that are manufactured at business sites, raw materials, intermediate products, recovered materials, and waste, as well as chemical structure designs and process designs in R&D.

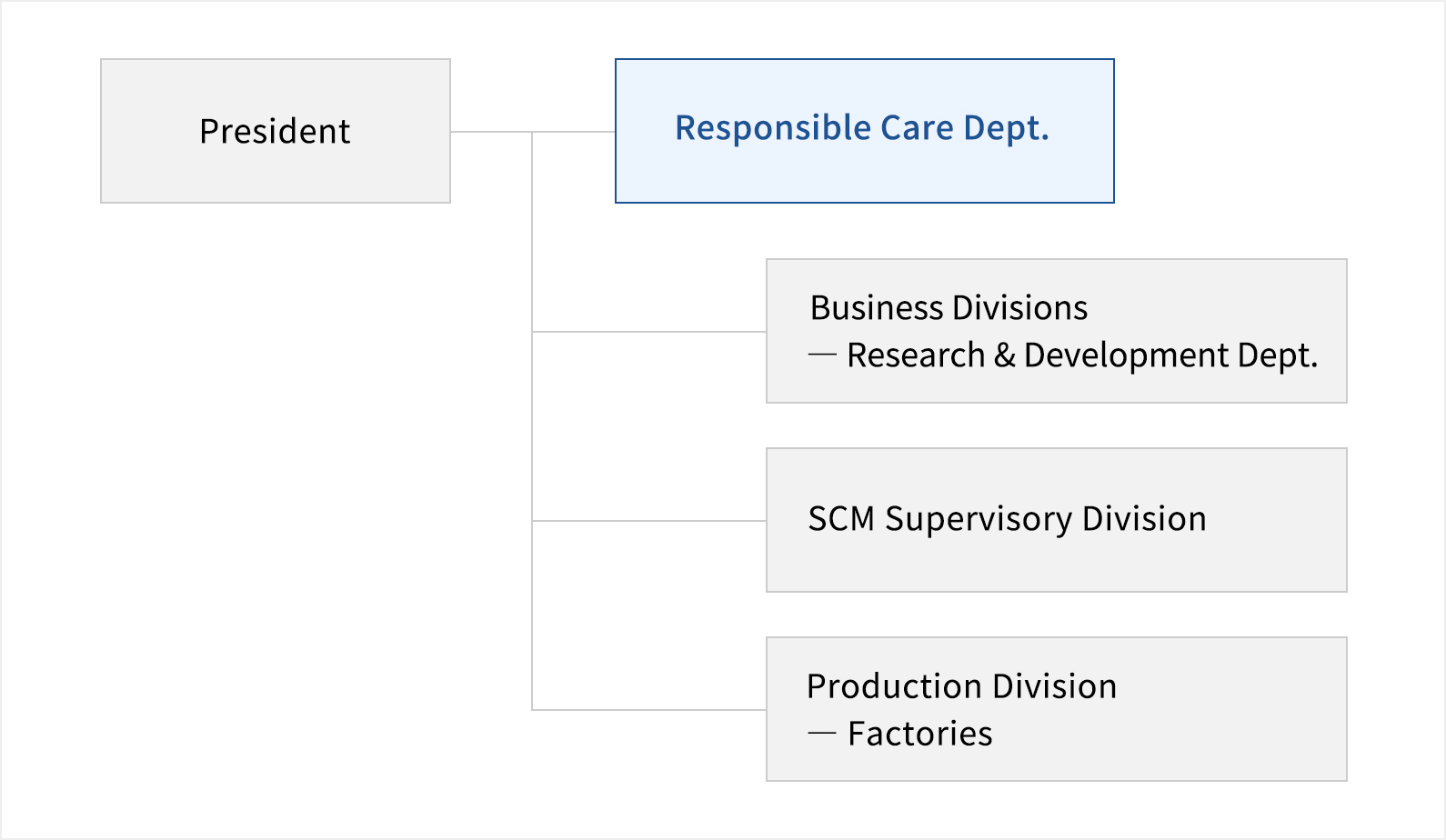

Bodies related to management of chemical substances and their roles

The General Manager of the Responsible Care Division serves as the supervisor. Respective divisions collaborate under the leadership of the General Manager to manage chemical substances. Discharge into the environment due to in handling in production activities is managed by the Production Division. Design management related to the product composition and manufacturing processes is undertaken through cooperation between the research department affiliated with a business division and the Production Division.

*Horizontally scrollable

| Headquarter | Main responsibility |

|---|---|

| Responsible Care Division |

|

| Each Business Division |

|

| Global Purchasing Division |

|

| Production Division |

|

Safe and appropriate handling of chemical substances

Our Group handles various chemical substances in its operations. Thus, it is essential to acquire knowledge about physical properties and the harmful effects of chemical substances. Regarding substances handled, respective departments organize workshops using safety data sheets (SDSs) and conduct risk assessment. Employees are encouraged to acquire qualifications for handling specified chemical substances whose harmful effects are particularly high, organic solvents, poisonous and deleterious substances, and hazardous materials for preventing fire and accidents. Plant engineers at factories are required to acquire qualifications as Class A hazardous materials engineers or Class B hazardous materials engineers (Group 4).

Status of qualifications in Japan

March, 2023

| Qualification | Number of qualified people (persons) |

|---|---|

| Hazardous materials engineers*1 | 1,242 |

| People/persons in charge of handling poisonous and deleterious substances | 21 |

| Organic solvent work chiefs | 517 |

| Specified chemical substance work chiefs | 466 |

| High pressure gas production safety managers | 224 |

| Pollution prevention managers*2 | 53 |

Total number of qualified people in factories and research laboratory

- Total number of dangerous goods handler class A and/or class B (Otsu1-6)

- Total number of pollution prevention manager; air, water, noise, and dioxin

Design management

When designing a product, it is necessary to translate the “functionality and performance” to meet the target needs into physical and chemical “properties,” and design the chemical composition to demonstrate the “physical properties.” To minimize the impact on individuals during the manufacture and use of products and their discharge into the environment and to ensure safety, examinations and checks are conducted from various viewpoints in the respective phases of composition design, process design, prototype production, and commercialization of products.

Inspections through research and development

*Horizontally scrollable

Click here for more information about considerations regarding harmful chemical substances used for products.

The page introduces products designed by giving consideration to the prevention of pollution and reduction of content based on the keywords of “solvent-free,” “halogen-free,” “free from harmful substances,” and “environmental residue.”

Click here for more information about considerations regarding harmful chemical substances used for products.

The page introduces products designed by giving consideration to the prevention of pollution and reduction of content based on the keywords of “solvent-free,” “halogen-free,” “free from harmful substances,” and “environmental residue.”

Discharge management

To reduce the negative impact of chemical substances discharged from production activities on the atmospheric, aquatic, and soil environments, we ensure compliance with laws and regulations and work on voluntary activities to reduce the discharge.

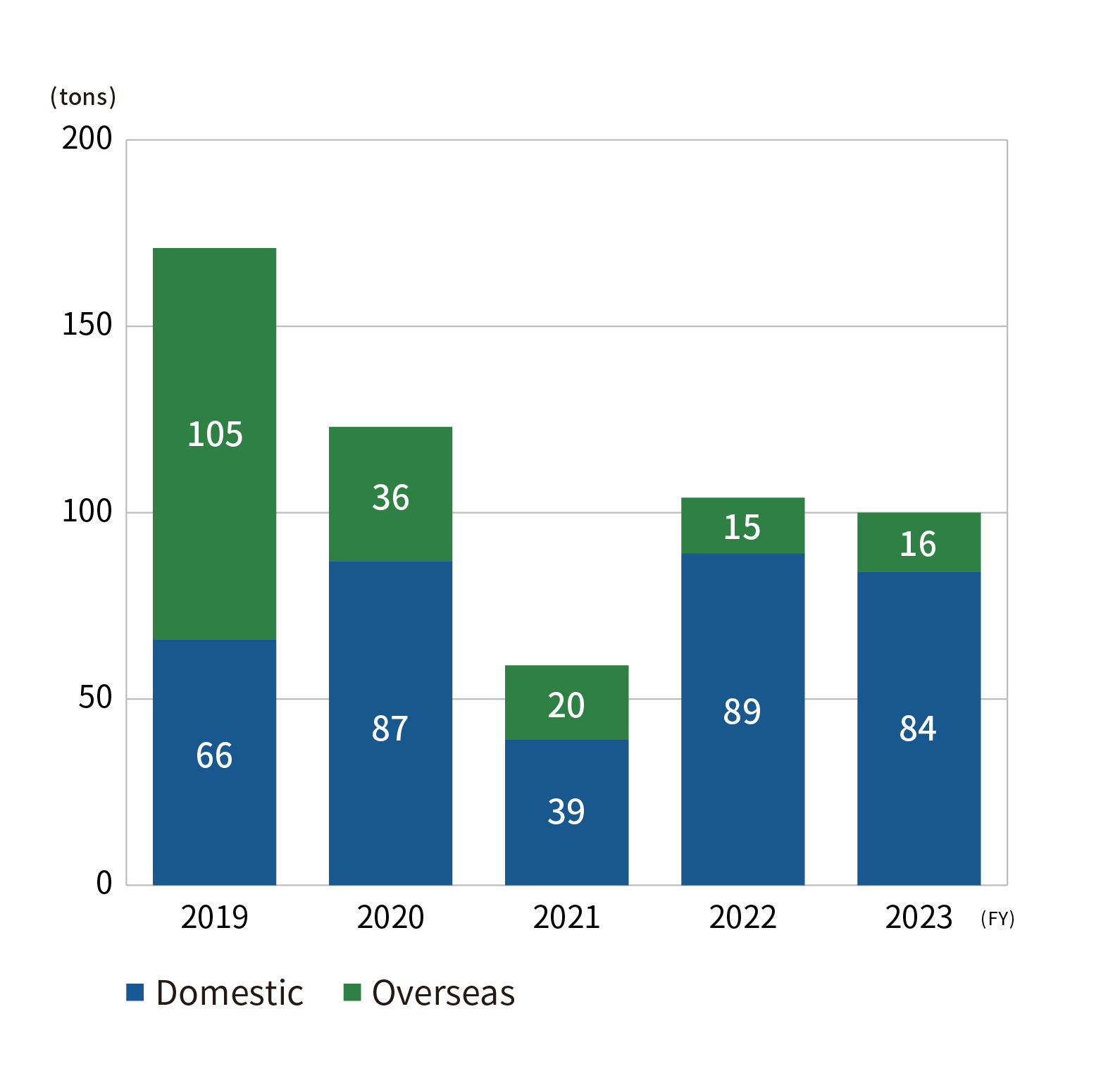

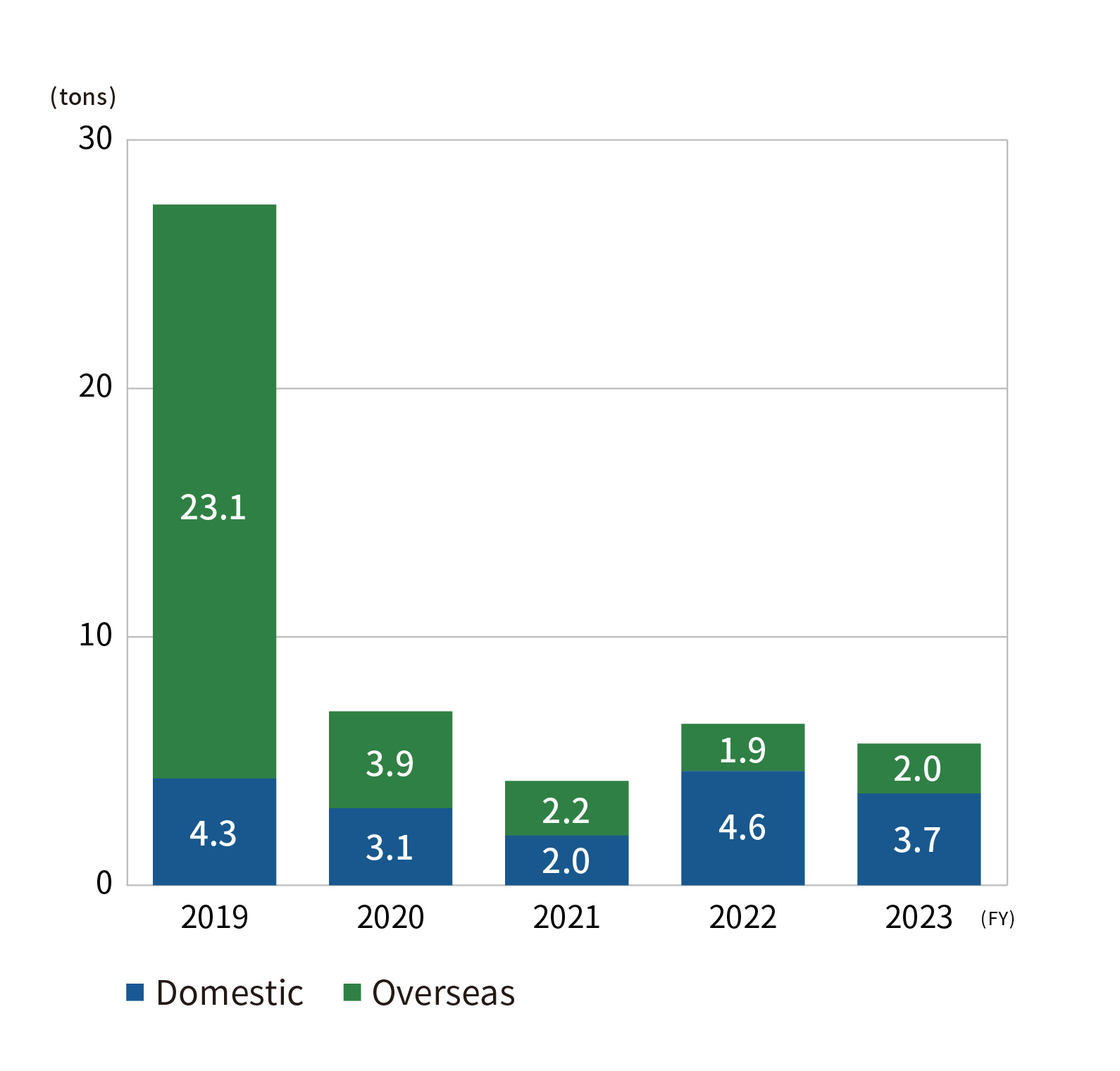

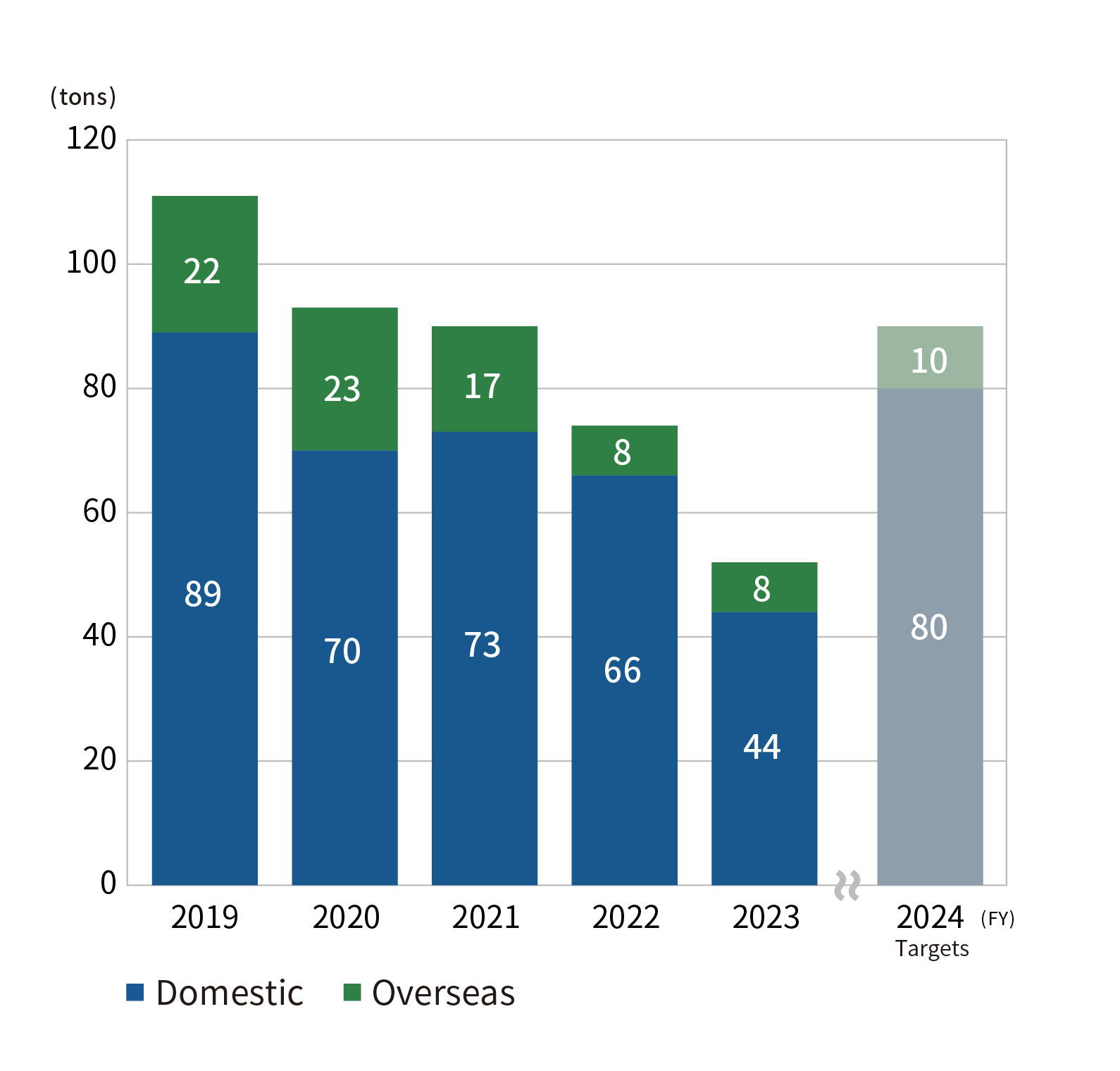

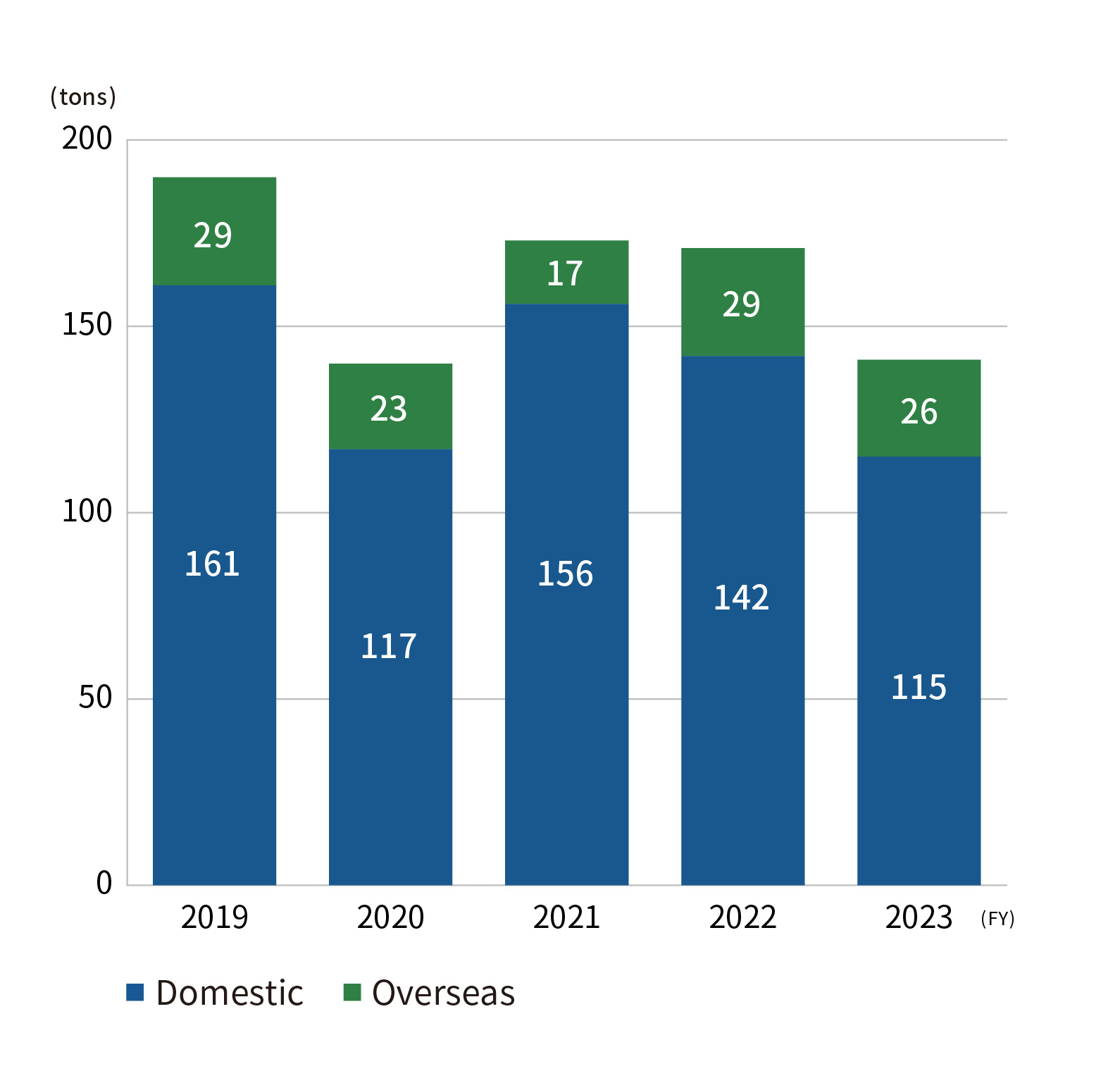

Conservation of the atmospheric environment

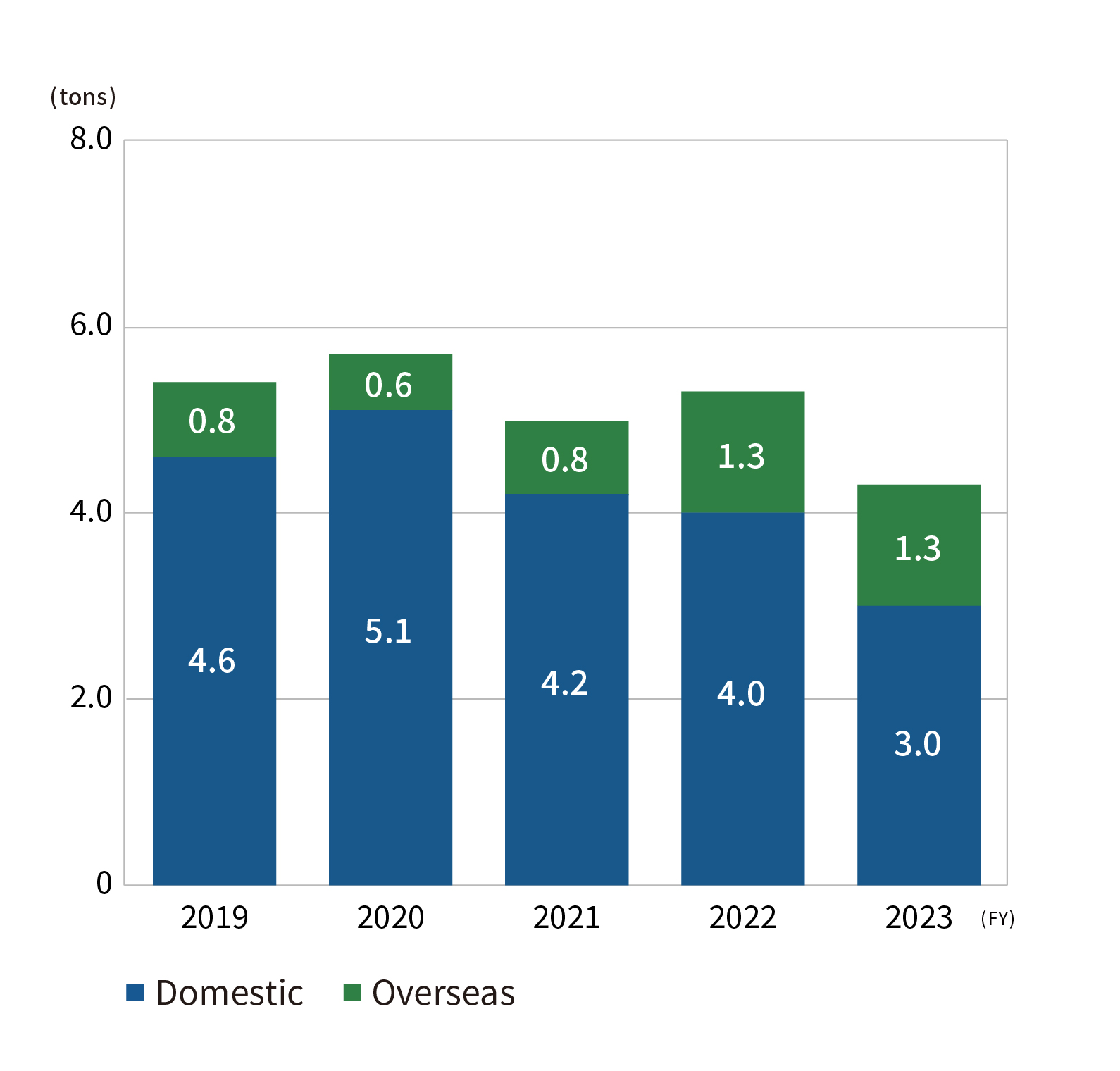

Business sites discharge combustion gases into the atmosphere (e.g., NOx, SOx) due to the use of boilers, cogeneration systems, and incinerators and volatile organic compounds (VOCs) generated from the operation of reaction tanks and storage tanks at plants. We endeavor to reduce the impact on the atmospheric environment through the maintenance and proper operation of such equipment and ancillary exhaust gas treatment equipment. Regarding VOCs, the targets for the final fiscal year (FY2024) of the Environmental Action Plan are 80 tons or less in Japan and 10 tons or less overseas. In FY2022, VOC emissions were 66 tons (−7 tons from the previous fiscal year) in Japan and 8 tons (−9 tons from the previous fiscal year) overseas, adding up to 74 tons for the entire Group and attaining the FY2024 targets.

- The overseas values of NOx, SOx, and soot and dust in FY2019 were high because abnormal measurement values were recorded at SDP GLOBAL (MALAYSIA) SDN. BHD. We checked the equipment and measurement methods. The values are normal in FY2020 and beyond.

- Scope of aggregation of VOCs: All the business sites in Japan and Sanyo Kasei (Thailand) Ltd. in FY2018. Sanyo Kasei (Nantong) Co., Ltd., San-Dia Polymers (Nantong) Co., Ltd., and SDP GLOBAL (MALAYSIA) SDN. BHD. were added in FY2019.

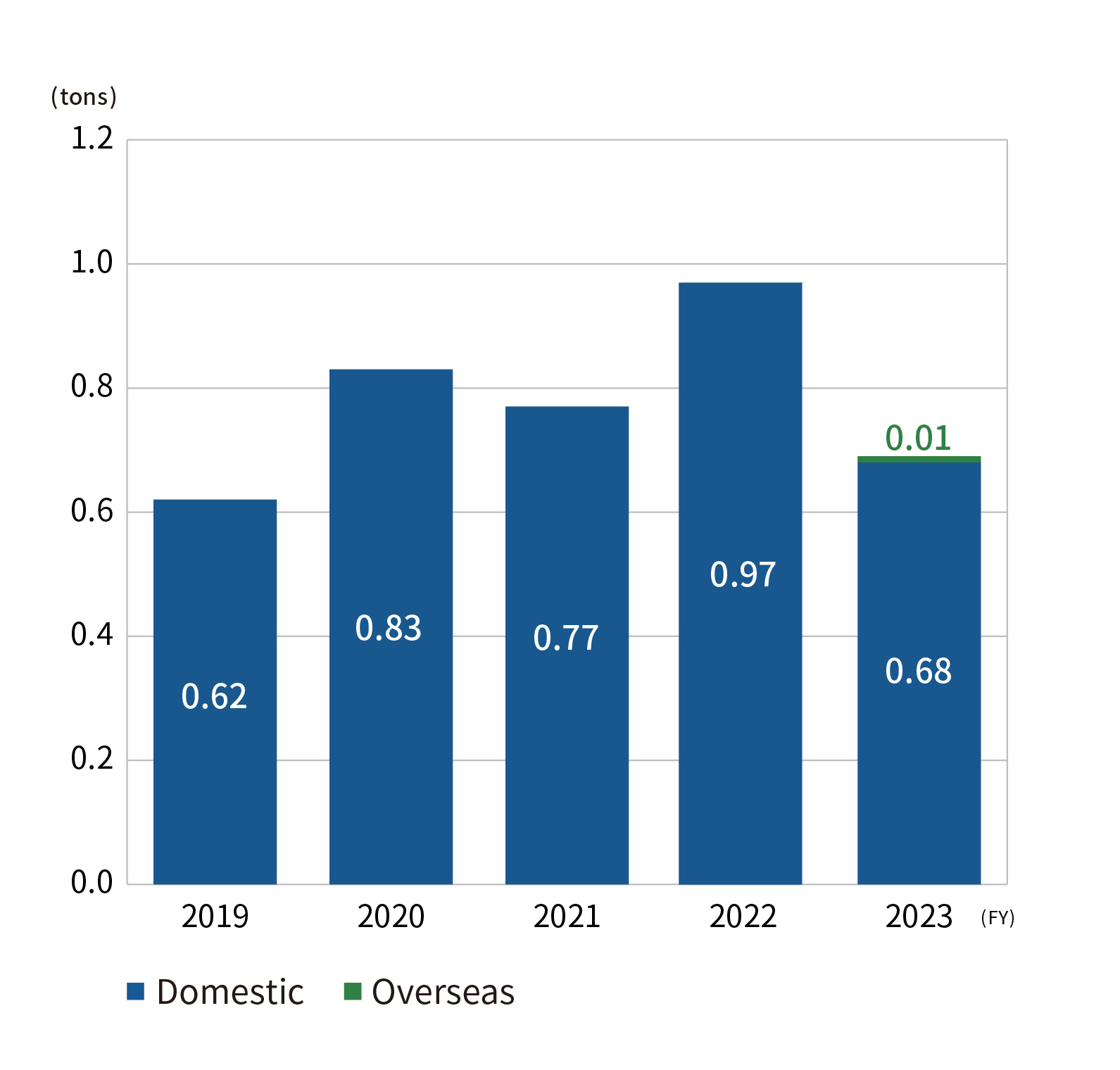

Conservation of the water environment

At the wastewater discharge pipes at business sites, voluntary management values stricter than the wastewater regulation values stipulated in laws and regulations are in place to manage the concentration by monitoring the status of wastewater.

We endeavor to prevent the discharge of pollutants into the aqueous environment through the appropriate maintenance of equipment, installation of dikes, and measures to prevent leakage at business sites.

Click here for information of discharge and environmental impacts.

Nagoya area (Nagoya Factory, SDP Global Co., Ltd. and San Nopco Ltd.) discharge to Ise Bay, and Kawasaki area (San Chemical Co., Ltd.) discharge to Tokyo Bay. Other facilities discharge to sewerage system.

Environmental conservation for soil and ground water

We do not perform landfill disposal at business sites. We also monitor the condition of ground water using observation wells at business sites. We conduct a voluntary soil survey on house premises during construction work to check for problems on an ongoing basis.

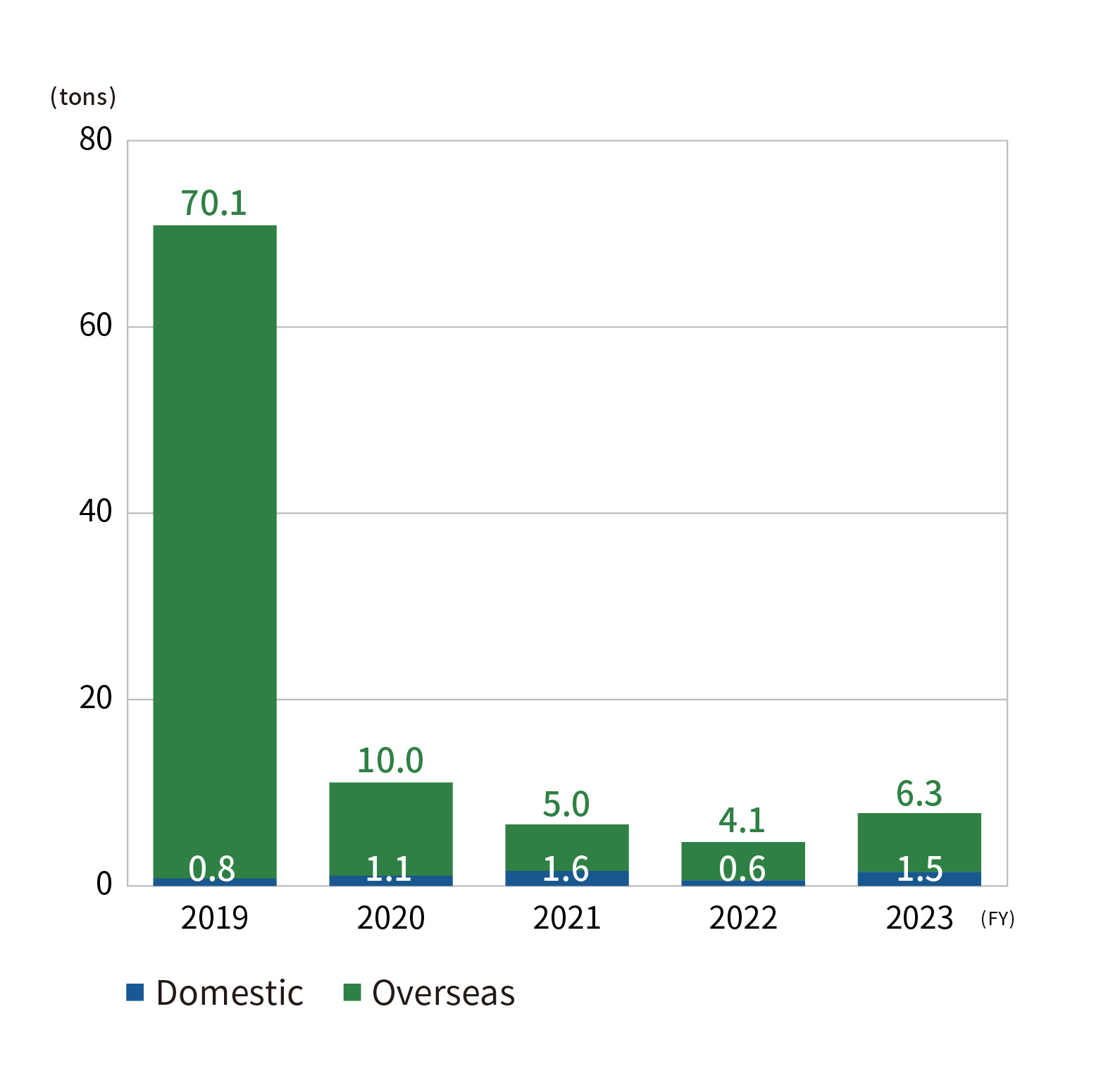

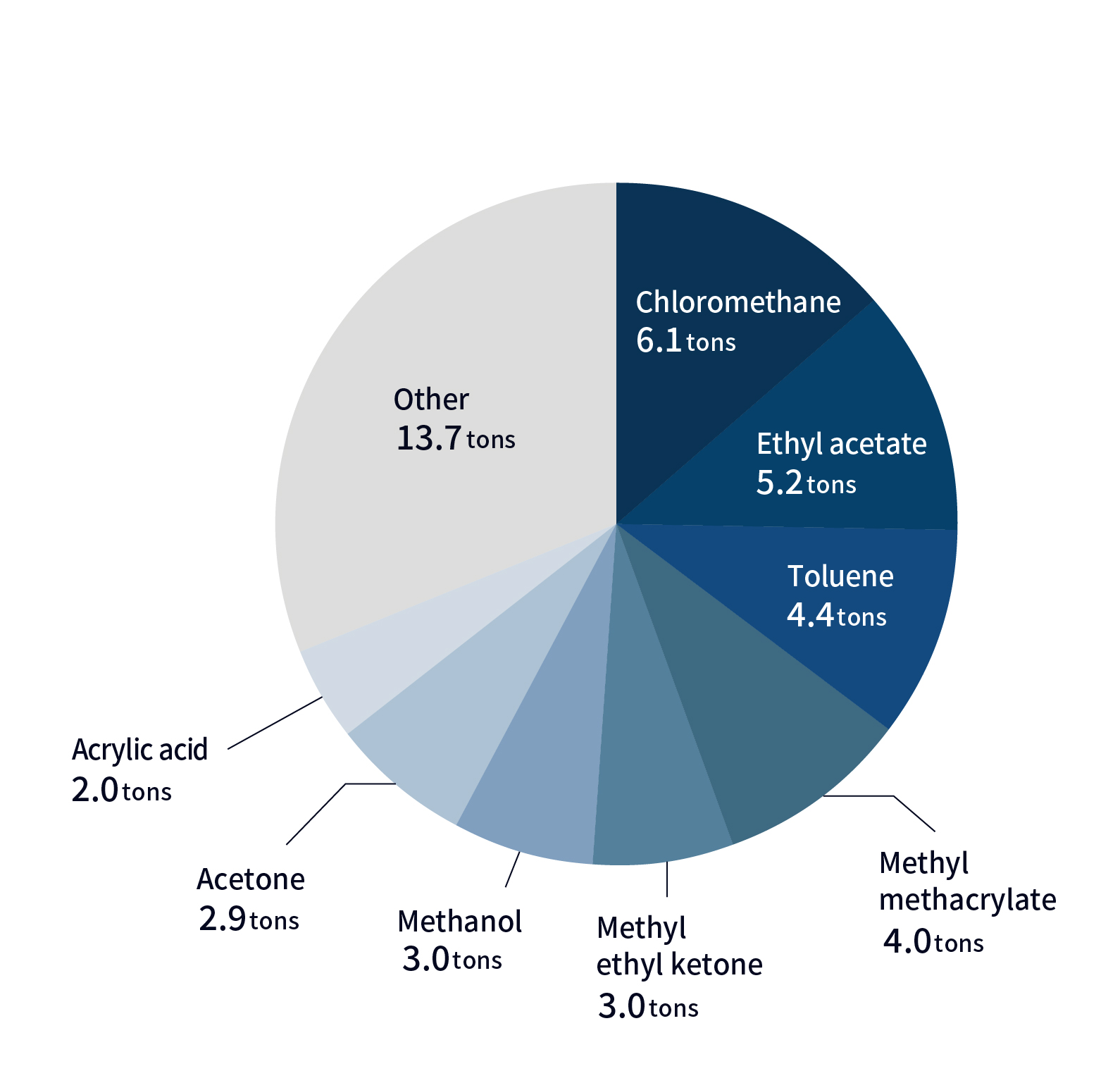

Compliance with the PRTR Law

In Japan and Thailand, a system is in place to notify the amount discharged to the environment and the migration amount in accordance with the PRTR Law.

Our Group has been working to reduce the discharge by determining the amount of VOCs outside the scope of the PRTR Law in addition to the amount of substances covered by the law discharged from business sites, and setting priorities.

In FY2022, we started to implement measures to reduce the discharge of chloromethane, whose discharge amount was the largest among the VOCs discharged in Japan, but against which no effective measures had been implemented.

We succeeded in reducing the amount of chloromethane, which had been excessively used, by improving the manufacturing process. In FY2022, consumption was reduced by about 2 tons. This is equivalent to a reduction in the discharge amount by up to 8.8 tons per annum. In overseas operations, the discharge amount will be reduced through combustion and adsorption treatment of exhaust gas by using discharge reduction technology refined in the operations in Japan.

Substances subject to PRTR Law in FY2022 (domestic facilities)

*Horizontally scrollable

| Number of handled substances | Volume (tons) |

Emissions to air (tons) |

Emissions to water (tons) |

Emissions to soil (tons) |

Transferred to waste (tons) |

|

|---|---|---|---|---|---|---|

| Sanyo Chemical | 121 | 102,292 | 35.5 | 0.3 | 0 | 507.7 |

| Domestic subsidiaries and affiliates | 57 | 129,195 | 6.0 | 0.0 | 0 | 9.5 |

| Total | 131 in total | 231,487 | 41.5 | 0.3 | 0 | 517.2 |

Click here for emissions / transfer data, and emission reduction measures.

Compliance on environmental matter

In FY2022, we did not receive any complaints about pollution, violate any law or regulation related to the environment, or have administrative direction or any lawsuits.