Policy

As a chemical manufacturer, the Sanyo Chemical Group is committed to contributing to the carbon neutrality of society as a whole, not only by reducing GHG emissions from its own business sites, but also by developing and providing product lines that help curb CO2 emissions. At the same time, we are actively undertaking energy conservation efforts through various measures to reduce energy consumption.

Targets and Results

*Horizontally scrollable

| Themes | FY2019 (base year) results | FY2020 | FY2021 | FY2022 | FY2023 | Evaluation | FY2024 target |

|---|---|---|---|---|---|---|---|

| GHG emissions (10,000 tons) |

31.1 Domestic: 17.6 Overseas: 13.5 |

30.8 Domestic: 15.7 Overseas: 15.1 |

27.6 Domestic: 15.3 Overseas: 12.3 |

25.5 Domestic: 14.6 Overseas: 10.9 |

23.1 Domestic: 12.3 Overseas: 10.8 |

Stayed within target standards | 29.5 or less |

| Percentage reduction (compared to FY2019) |

- | 1% | 11% | 18% | 26% | 5% or above | |

| Energy consumption (10,000 kL) |

14.7 Domestic: 9.0 Overseas: 5.7 |

14.6 Domestic: 8.1 Overseas: 6.5 |

13.2 Domestic: 8.1 Overseas: 5.1 |

12.3 Domestic: 7.8 Overseas: 4.5 |

10.8 Domestic: 6.5 Overseas: 4.3 |

Stayed within target standards | 14.0 or less |

| Percentage reduction (compared to FY2019) |

- | 1% | 10% | 16% | 27% | 5% or above |

Scope: All facilities of Sanyo Chemical Industries, Ltd., all domestic subsidiaries & affiliates, and overseas subsidiaries & affiliates that have production bases*

- Sanyo Chemical Texas Industries, LLC; Sanyo Kasei (Thailand) Ltd.; Sanyo Kasei (Nantong) Co., Ltd.; San-Dia Polymers (Nantong) Co., Ltd.; SDP GLOBAL (MALAYSIA) SDN. BHD.

GHG Emissions Reduction and Energy Conservation

Current GHG Emissions (FY2023)

*Horizontally scrollable

| Emission/absorption/ reduction contribution classification |

GHG type | Volume (CO2 equivalent) |

|

|---|---|---|---|

| Environmental impact | Emission | Direct emissions from fuel oil combustion at business sites (Scope 1) | 105 thousand tons |

| Methane (generated from septic tanks) | 30 Tons | ||

| Nitrous oxide (byproduct of combustion) | 156 tons | ||

| Other GHG (NF3, PFC, SF6) | No emissions | ||

| CFC leakage from refrigerators and air conditioners | 241 tons | ||

| Indirect emissions from the use of electricity, heat, or steam purchased at business sites (Scope 2) (market basis) | 126 thousand tons | ||

| Supply chain emissions (Scope 3) | 1,911 thousand tons | ||

| Impact reduction | Absorption | Increase in forest CO2 absorption (due to tree thinning project) | 20 tons |

| Reduction contribution | CO2 reduction by users using our products that contribute to reducing CO2 emissions | 535 thousand tons | |

The GHG emitted from our business sites other than CO2 consist of methane from septic tanks, nitrous oxide as a combustion byproduct, and CFCs leaked from refrigeration units, etc. (427 tons of CO2 equivalent in total).

These non-CO2 GHG emissions are negligible at 0.19% of Scope 1+2 emissions, with CO2 emissions accounting for almost all supply chain emissions, including Scope 3 emissions.

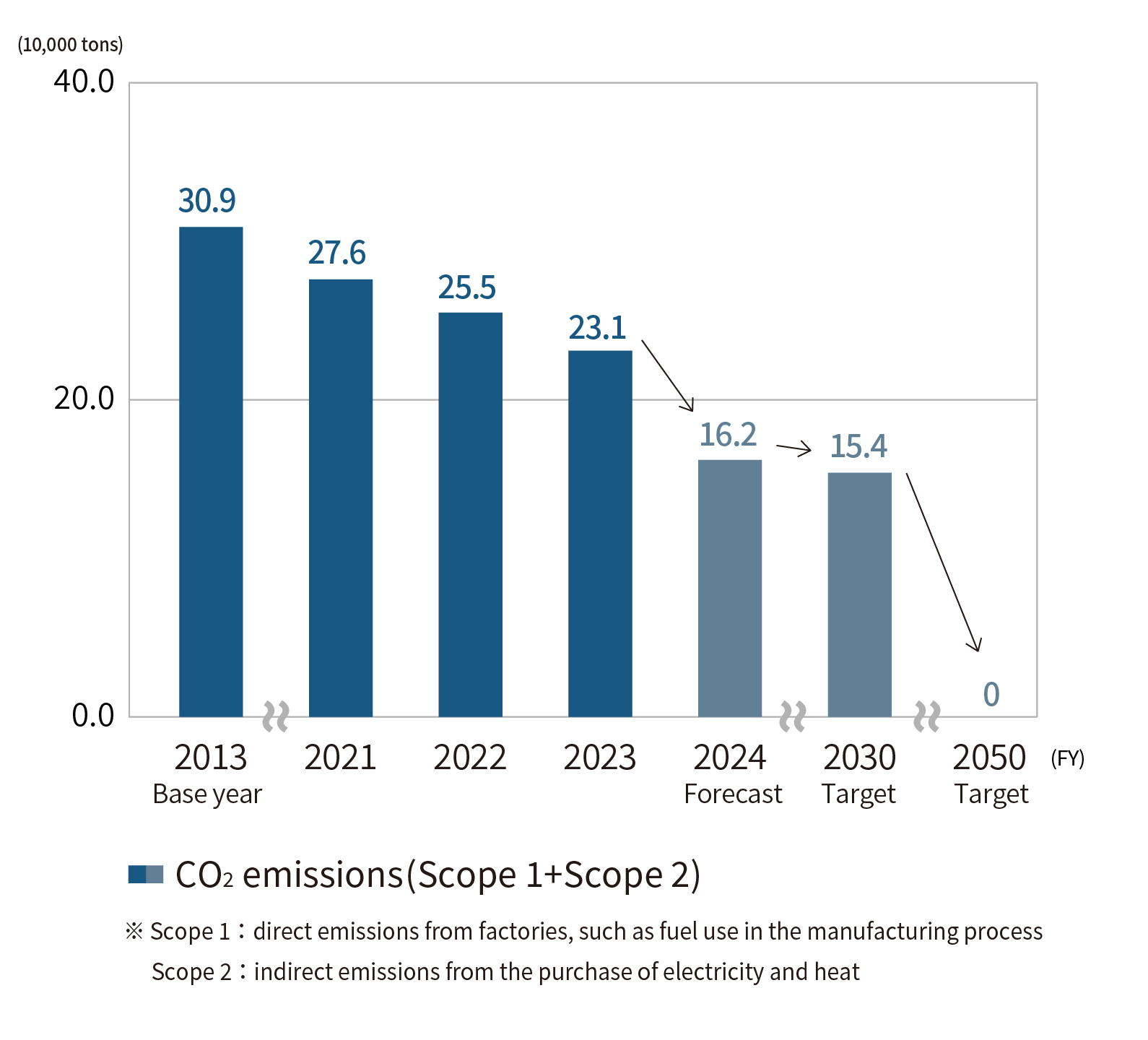

Medium- to Long-term GHG (Scope 1+2) Emissions Reduction Targets

*Horizontally scrollable

| FY | Group targets (CO2 equivalent) | Notes |

|---|---|---|

| 2013 | 309 thousand tons | Base year |

| 2030 | 154 thousand tons | Interim target (halved vs. base year) |

| 2050 | Net zero | Final target (to achieve carbon neutrality) |

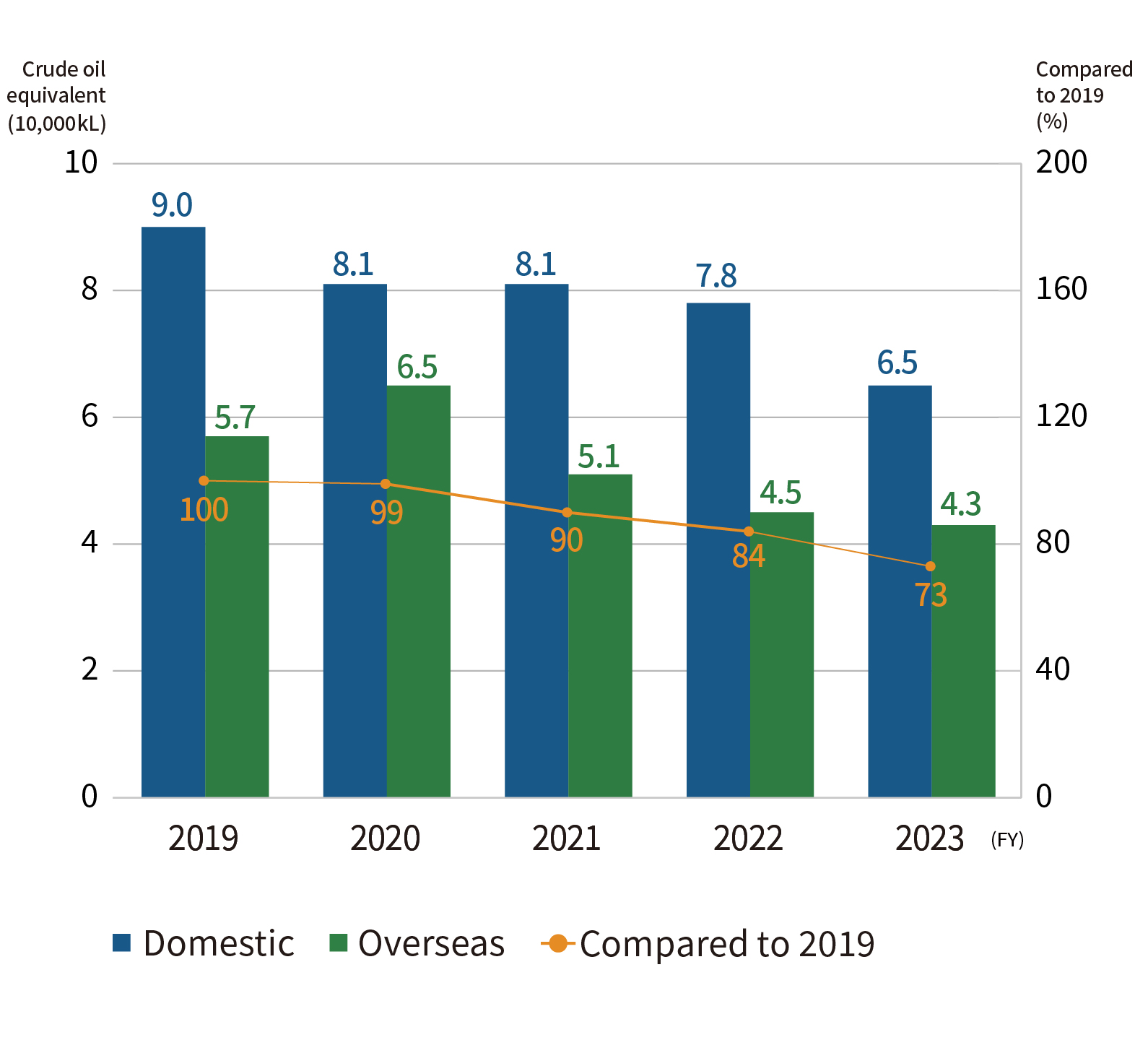

Energy consumption (Scope 1+2)

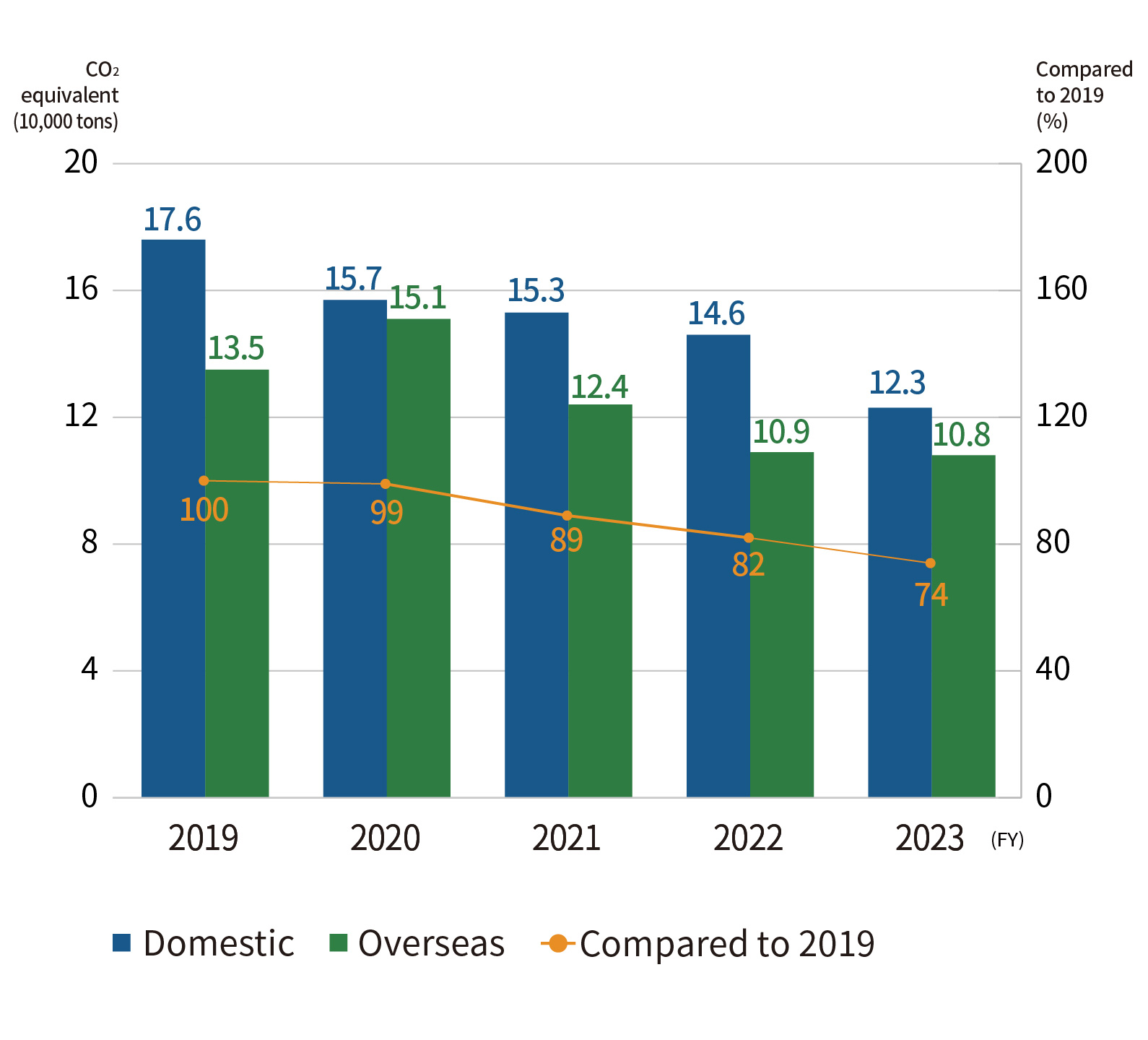

GHG emissions (Scope 1+2)

In FY2023, the entire group's energy consumption in crude oil equivalent was 108 thousand kL (65 thousand kL in Japan and 43 thousand kL overseas), a decrease of 73% from FY2019, due to reduced production volume and implementation of energy conservation and CO2 emission reduction measures. For the same reasons, GHG emissions in CO2 equivalent also decreased 74% from FY2019 to 231 thousand tons (123 thousand tons in Japan and 108 thousand tons overseas).

Fluorocarbons

Our domestic business sites own approximately 800 commercial air conditioners and refrigeration/freezer units that use fluorocarbons. These units require equipment inspections and reporting of the volume of fluorocarbons leaked, and we conduct these inspections every year according to the law. Total fluorocarbons leakage volume in FY2023 was 84 kg (including 0.35 kg of ozone-depleting fluorocarbons), which is equivalent to 241 tons of CO2 as a GHG.

Measures to achieve carbon neutrality

Since most of the GHG emitted from our group's business sites is CO2, we seek to achieve carbon neutrality throughout the supply chain by focusing on efficient energy usage by building and operating an energy management system and energy conversion (fossil fuels to solar power and hydrogen) for Scope 1+2 emissions; on the use of low-GHG raw materials (biomass raw materials and other raw materials that contribute to carbon neutrality) for Scope 3 emissions; on energy-saving effects, GHG emissions reduction, and resource conservation effects when using our products; and on developing technologies for CCU (Carbon Dioxide Capture and Utilization). The New Medium-Term Management Plan calls for implementing a “Monozukuri Transformation," a series of business process reforms throughout the supply chain that will involve digital transformation (DX). This effort will involve promoting initiatives that lead to carbon neutrality, such as a fundamental re-examination of production processes and the use of low-GHG raw materials.

≫ Disclosure Based on TCFD Recommendations

Products made with biomass

Biomass is increasingly replacing petrochemical feedstock as a more renewable and sustainable material. For its part, the Sanyo Chemical Group has developed raw materials for sunscreen formulations derived from rice bran and vegetable leather made from wood. We have also obtained ISCC PLUS certification for some of the polyethylene glycol products we handle. We will continue to develop biomass-based high-performance products that contribute to reducing our environmental impact.

Endorsed Initiatives

*Horizontally scrollable

| Initiative | Sponsoring organization |

|---|---|

| TCFD | Task Force on Climate-related Financial Disclosures |

| Challenge Zero by Keidanren | Keidanren (Japan Business Federation) |

| GX League | Ministry of Economy, Trade and Industry |

| Kyoto's Challenge to Net-Zero by 2050 | Kyoto City |

Disclosure Based on TCFD Recommendations

The Sanyo Chemical Group showed support for the recommendations by the Task Force on Climate-related Financial Disclosures (TCFD) in December 2021. To help improve social sustainability and enhance our corporate value, we evaluate the effects of climate-related risks and opportunities on relevant financial indicators and reflect them in our management strategies.

As a chemicals manufacturer, it is our corporate responsibility not only to develop products that help reduce CO2 emissions, but also to contribute to carbon neutrality by reducing the CO2 emissions from our own business sites. Our group has steadily reduced CO2 emissions since FY2017 in accordance with the government's energy conservation targets. We will actively work on initiatives across the Group toward a “50% reduction in CO2 emissions by 2030 (compared to the FY2013 level) and net zero by 2050,” which are the targets of our Sustainability Action Plan, while aiming to reduce emissions across the supply chain.

Governance

Climate change governance is part and parcel of sustainability governance.

Strategy

In developing strategies, risk management, indicators, and targets related to climate change, the Sanyo Chemical Group conducted scenario analyses in line with TCFD recommendations for its main business areas, including Toiletries and Health Care, Petroleum and Automotives, Plastics and Textiles, Information and Electrics/Electronics, and Environmental Protection, Construction and Others. We also selected business risks and opportunities and evaluated their significance. In FY2023, in addition to the 1.5°C scenario, in which a transition to a decarbonized society is realized, a qualitative analysis was conducted for the 4°C scenario, in which climate change advances with no progress in global decarbonization. The results were then discussed and determined by the Sustainable Management Committee.

Scenario Concept

*Horizontally scrollable

| 1.5°C scenario |

A scenario where CO2 emissions are strongly curbed to limit the temperature rise to +1.5°C (Reference) International Energy Agency's long-term outlook: “Net Zero Emissions by 2050” |

| 4°C scenario |

A scenario in which climate change progresses to the point where the global average temperature rises by 4°C by the end of the 21st century compared to pre-industrial times (Reference) Intergovernmental Panel on Climate Change’s Sixth Assessment Report (IPCC AR6) “SSP3-7.0” |

*Horizontally scrollable

| World anticipated in the 1.5°C scenario |

Top priority placed on the realization of a decarbonized society, and implementation of an ambitious climate change policy

|

|---|---|

| World anticipated in the 4°C scenario |

A slow decarbonization transition with priority placed on economic activities, and implementation of climate change policies only in the current situation

|

Risk management

Our countermeasures to the main risks and opportunities and the results of impact assessment were compiled. Regarding the impact assessment, the impact in terms of the amount of money was estimated and classified into three categories (high, intermediate, and low), depending on the magnitude. Based on these scenarios, we examined climate change risk in our group from various perspectives.

We anticipate tighter regulations due to policies such as carbon pricing toward decarbonization, and a demand shift to materials suitable for decarbonization as the main climate change risks of the Group. We also need to consider the accelerated transition to a circular economy and the progress of innovative technologies toward a decarbonized society.

To reduce CO2 emissions from our business sites, in particular, we are considering the use of CCU (Carbon Dioxide Capture and Utilization) and switching to hydrogen and other energy sources as measures for our Nagoya and Kashima factories, which account for most of the Group's CO2 emissions. We are also considering process improvements for individual products to reduce CO2 emissions.

For opportunities, we contribute to the reduction of CO2 emissions by actively promoting sustainable management, including a fundamental review of our business portfolio.

The Sanyo Chemical Group’s Countermeasures to the Main Risks and Opportunities of Climate Change

*Horizontally scrollable

| Classification | Scenario | Climate change risk item | Impact of climate change risks on the Sanyo Chemical Group | Impact assessment | Countermeasure |

|---|---|---|---|---|---|

| Risk | 1.5℃ | Introduction / raising of carbon tax | Increase in energy procurement costs | High |

|

| Reduction of CO2 emissions | Decrease in demand for our products with high GHG emissions | High |

|

||

| Replacement with low-carbon products | Reduction of sales opportunities for our products that do not use biomass raw materials | High |

|

||

| Recycling regulations | Decrease in demand for our products that do not use recycled raw materials | Intermediate |

|

||

| Changes in consumer behavior | Decrease in sales of gasoline-fueled and hybrid vehicles | High |

|

||

| 4℃ | Natural disasters (typhoons, heavy rain, drought, etc.) | Supply chain disruptions Damage to company facilities | High |

|

|

| Opportunity | 1.5℃ | Introduction / raising of carbon tax | Spread of CCUS Increase in demand for our products that contribute to reducing GHG emissions |

High |

|

| Reduction of CO2 emissions | Expansion of the market for products that contribute to reducing GHG emissions | High |

|

||

| Replacement with low-carbon products | Market expansion of products made from bio-based raw materials | High |

|

||

| Recycling regulations | Increase in demand for recyclable products | Intermediate |

|

||

| Changes in consumer behavior | Reduction of weight of batteries in line with the higher mileage of vehicles Increase in sales of electric vehicles |

Intermediate |

|

||

| 4℃ | Natural disasters (typhoons, heavy rain, etc.) Rising average temperatures |

Increase in demand for paint binders due to growing demand for heat insulating paints | Intermediate |

|

|

| Expansion of the market for agricultural products that are resistant to environmental changes | Intermediate |

|

|||

| Increase in demand for water quality improvement as a measure against water quality deterioration | Intermediate |

|

- The impact assessment is based on the estimated monetary value, and is classified as high, intermediate, or low depending on the magnitude of the impact.

Metrics and targets

New Medium-Term Management Plan 2025 lays out various indicators and goals for efforts aimed at solving environmental problems.

One of these is an indicator for reducing greenhouse gas emissions (Scopes 1, 2, and 3). Along with cogeneration and solar power generation, we will engage in CCU and utilize green hydrogen.

The other indicator is for expanding our lineup of products aimed at contributing to carbon neutrality.

Scope 1 and Scope 2: CO2 emissions from business sites

In 2005, when the Kyoto Protocol came into effect, we established the “Action Policy Concerning the Kyoto Protocol" and formed working groups for global warming countermeasures with each business site in Japan to improve the efficiency of energy use, improve production processes, and switch fuels.

In FY2018, we implemented a management policy to focus on the sale of high value-added products. This led to our discontinuing the sale of low value-added products, resulting in a decrease in production, especially in Japan. This kicked off a decline in the CO2 emission intensity per volume of production for our domestic products. In addition, the decision to withdraw from the superabsorbent polymers business in FY2023 and the resulting significant change in our business portfolio are expected to enable us to significantly reduce CO2 emissions from our own facilities in FY2024 and beyond, enabling us to achieve our "50% reduction in CO2 emissions in FY2030 (compared to FY 2013)" goal ahead of schedule. The Group will continue to promote initiatives to achieve net zero emissions by 2050.

Target of CO2 emissions reduction (Scope 1, Scope 2)

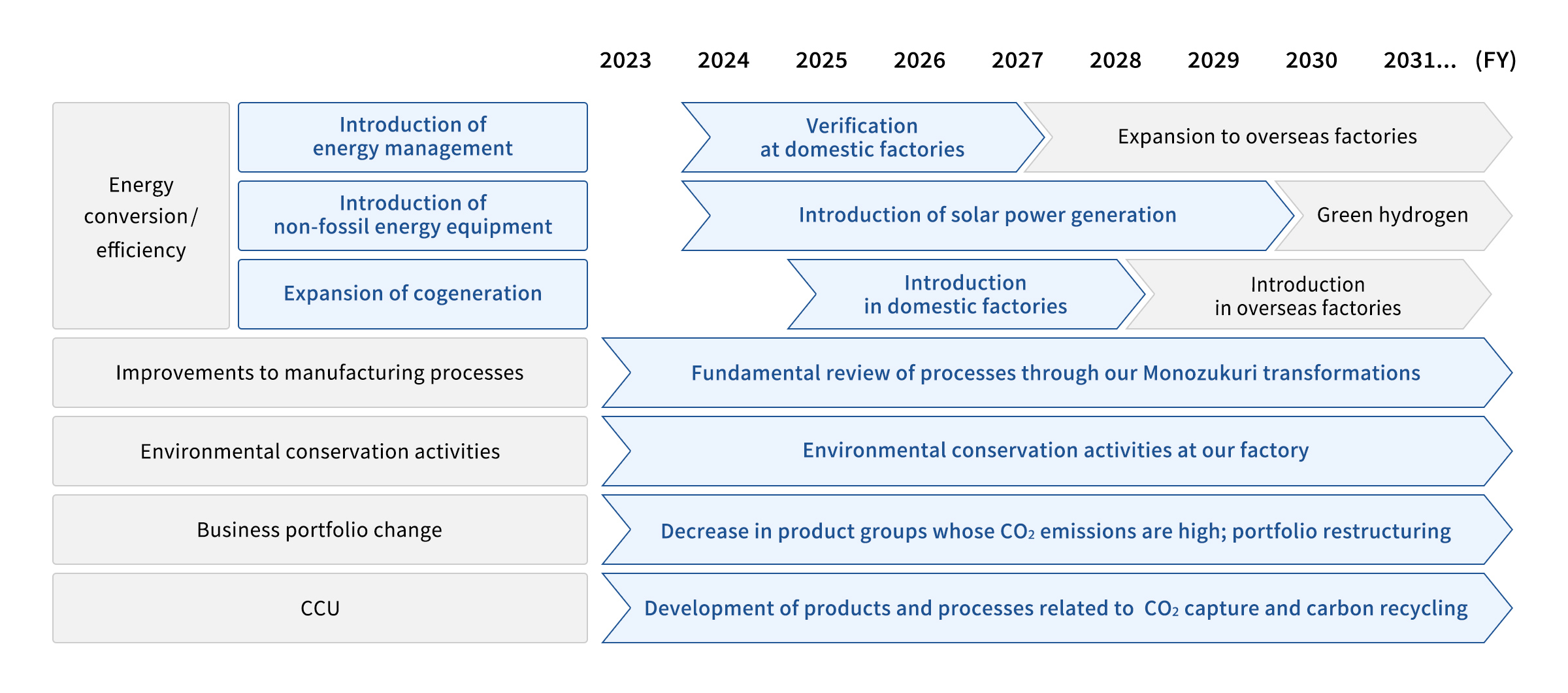

Roadmap toward carbon neutrality

As a measure to reduce GHG emissions, we will engage in energy transition (introduce energy management, deploy solar power and green hydrogen production facilities, and expand cogeneration) and review manufacturing processes. We also aim to become “net zero emissions by 2050” by introducing CCU.

*Horizontally scrollable

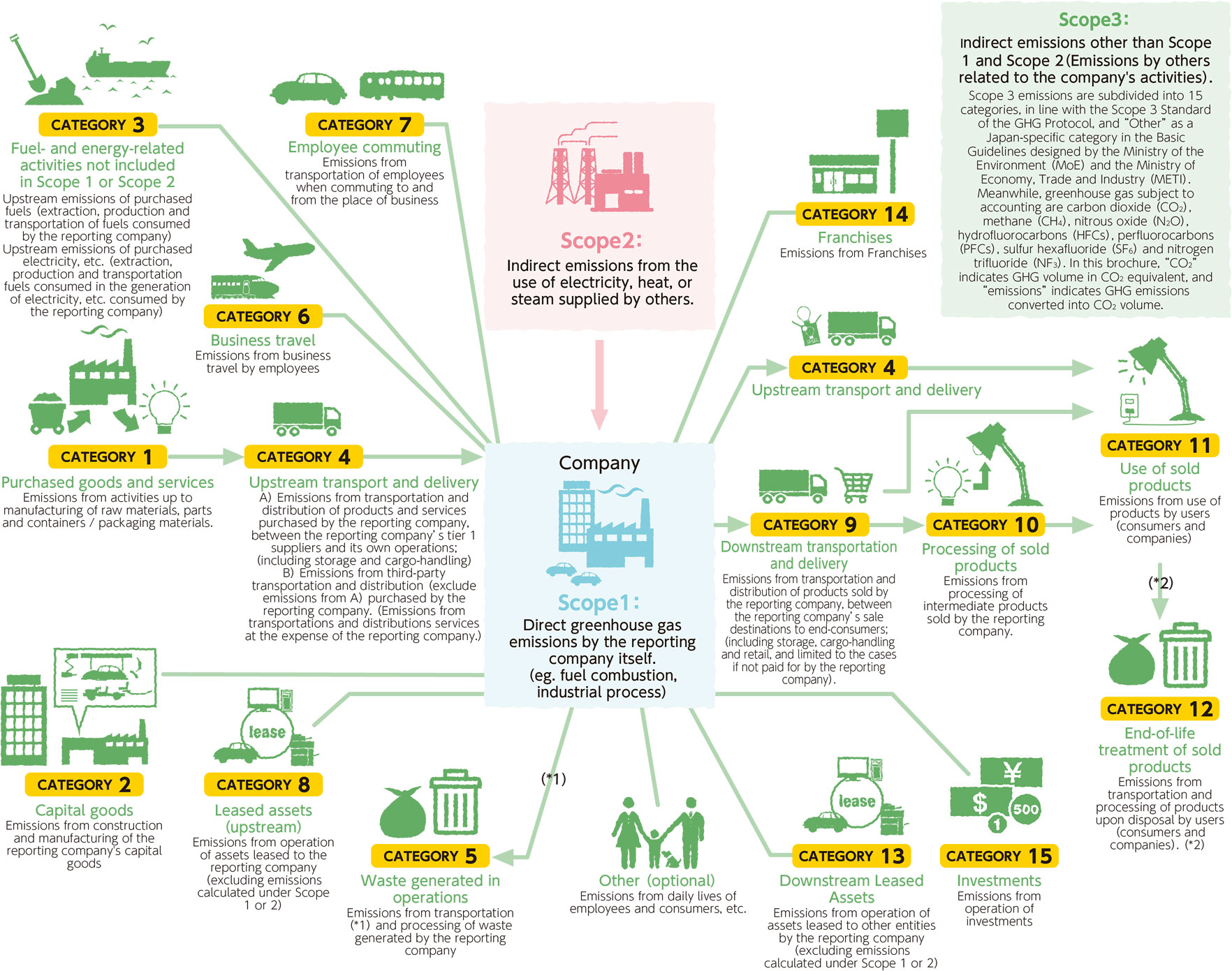

Emissions through the supply chain (Scope 3)

We have calculated direct emissions from fuel use (Scope 1), indirect emissions from the use of electricity, heat, and steam supplied by others (Scope 2), and emissions through the supply chain (Scope 3).

In FY2023, emissions from our business sites (Scope 1 + Scope 2) were 231 thousand tons, while Scope 3 emissions were 1,911 thousand tons. CO2 emissions from purchased raw materials and CO2 emissions from the disposal of finished products using our products account for 53% and 39% of total Scope 3 emissions, respectively.

Greenhouse Gas Emissions in the Group's Supply Chain

*Horizontally scrollable

CO2 emissions from the use, processing, and transportation of our products at and to our customers' sites are not calculated due to the difficulty of collecting the necessary data for such calculation.

Starting in FY2022, we use a standard questionnaire tool (common SAQ) formulated by the Global Compact Network Japan to reduce CO2 emissions through the supply chain.

Toward the future

Through business activities guided by our Company mission, the Sanyo Chemical Group will contribute not only to our own carbon neutrality, but also to a more sustainable society.