Site Report

[Sanyo Chemical domestic facilities]

Nagoya Factory

The Nagoya Factory has our largest production capacity and is located in a coastal industrial zone in South Nagoya. The group company SAN NOPCO LIMITED is also located on the site.

| Location | 31-1, Shinpomachi, Tokai, Aichi |

|---|---|

| Main products | Thermoplastic polyurethane beads for the interior parts of automobiles (TUB), polyurethane products, base materials for electronic materials, surfactants, specialty chemicals |

| Started operations | 1968 |

| Site area | Approx. 100,000 ㎡ |

| ISO certification | ISO9001: obtained in 1998 |

| Employees | 313 (as of March 31, 2025) |

| INPUT | |||

|---|---|---|---|

| Energy | Energy (crude oil equivalent) |

23,324 | kL |

| Raw materials | Purchased raw materials and containers | 72,410 | tons |

| Water resources | Water withdrawal | 2,103 | thousand ㎥ |

| Tap water | 40 | thousand ㎥ |

|

| Industrial water | 2,063 | thousand ㎥ |

|

| OUTPUT to the Environment | ||||

|---|---|---|---|---|

| Global environment | GHG (CO2 equivalent) | 49,406 | tons | |

| Air quality | NOx | 45.3 | tons | |

| SOx | 1.1 | tons | ||

| Soot and dust | 1.7 | tons | ||

| PRTR substances | 5.4 | tons | ||

| VOC emissions | 12.6 | tons | ||

| Fluorocarbons (CO2 equivalent) | 13 | tons | ||

| Water quality | Water discharge | 1,690 | thousand ㎥ | |

| COD | 9.1 | tons | ||

| Phosphorus | 0.2 | tons | ||

| Nitrogen | 1.7 | tons | ||

| PRTR substances | 0.4 | tons | ||

| Waste | Outsourced waste treatment | 2,542 | tons | |

| External recycling | 2,542 | tons | ||

| External landfill | 0 | tons | ||

| Waste plastics | 593 | tons | ||

| PRTR substances | 89.3 | tons | ||

| Soil condition | No emissions | |||

Kinuura Factory

The Kinuura Factory was built for producing alkylene oxide adducts (AOAs) as our third domestic base, following Nagoya Factory and San Chemical Co., Ltd.

| Location | 4-43, Nitto-cho, Handa, Aichi |

|---|---|

| Main products | Raw materials for polyurethane foams |

| Started operations | 2010 |

| Site area | Approx. 140,000 m² |

| ISO certification | ISO9001: obtained in 2010 |

| Employees | 23 (as of March 31, 2025) |

| INPUT | |||

|---|---|---|---|

| Energy | Energy (crude oil equivalent) |

1,150 | kL |

| Raw materials | Purchased raw materials and containers | 36,104 | tons |

| Water resources | Water withdrawal | 42 | thousand ㎥ |

| Tap water | 1 | thousand ㎥ |

|

| Industrial water | 41 | thousand ㎥ |

|

| OUTPUT to the Environment | ||||

|---|---|---|---|---|

| Global environment | GHG (CO2 equivalent) | 2,172 | tons | |

| Air quality | NOx | 0.5 | tons | |

| SOx | 0 | tons | ||

| Soot and dust | 0 | tons | ||

| PRTR substances | 0.2 | tons | ||

| VOC emissions | 0.2 | tons | ||

| Fluorocarbons (CO2 equivalent) | 0 | tons | ||

| Water quality | Water discharge | 0.7 | thousand ㎥ | |

| COD | 0 | tons | ||

| Phosphorus | 0 | tons | ||

| Nitrogen | 0 | tons | ||

| PRTR substances | 0 | tons | ||

| Waste | Outsourced waste treatment | 212 | tons | |

| External recycling | 212 | tons | ||

| External landfill | 0 | tons | ||

| Waste plastics | 0 | tons | ||

| PRTR substances | 0 | tons | ||

| Soil condition | No emissions | |||

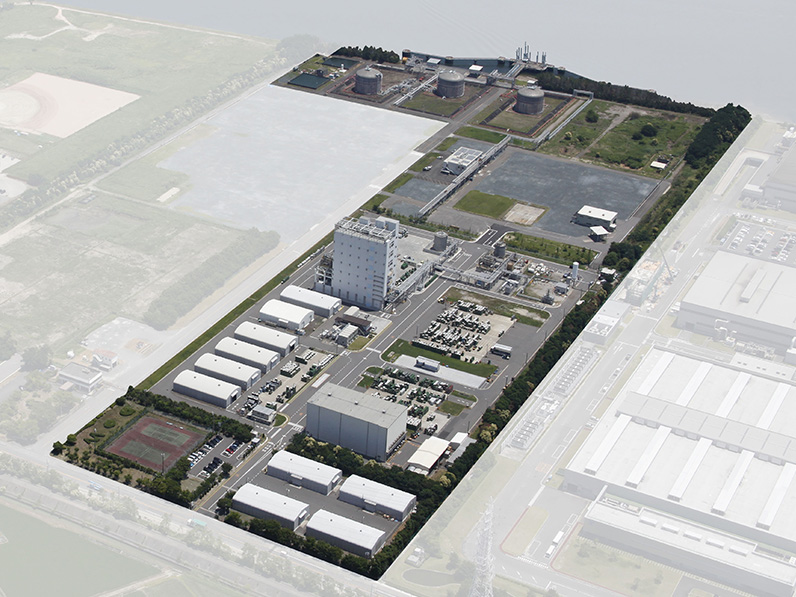

Kashima Factory

Located in industrial park in Ibaraki Prefecture, the Kashima Factory was built in 1976 to serve as Sanyo Chemical's principal production and distribution facility in the Kanto area.

| Location | 11-1, Sunayama, Kamisu, Ibaraki |

|---|---|

| Main products | Toner intermediates, toner resins, lubricant additives, permanent antistatic agents, etc. |

| Started operations | 1976 |

| Site area | Approx. 130,000 m² |

| ISO certification | ISO9001: obtained in 1997 |

| Employees | 167 (as of March 31, 2025) |

| INPUT | |||

|---|---|---|---|

| Energy | Energy (crude oil equivalent) |

14,551 | kL |

| Raw materials | Purchased raw materials and containers | 41,168 | tons |

| Water resources | Water withdrawal | 654 | thousand ㎥ |

| Tap water | 15 | thousand ㎥ |

|

| Industrial water | 639 | thousand ㎥ |

|

| OUTPUT to the Environment | ||||

|---|---|---|---|---|

| Global environment | GHG (CO2 equivalent) | 20,883 | tons | |

| Air quality | NOx | 0.2 | tons | |

| SOx | 0 | tons | ||

| Soot and dust | 0 | tons | ||

| PRTR substances | 15.2 | tons | ||

| VOC emissions | 21.1 | tons | ||

| Fluorocarbons (CO2 equivalent) | 136 | tons | ||

| Water quality | Water discharge | 734 | thousand ㎥ | |

| COD | 139 | tons | ||

| Phosphorus | 0.4 | tons | ||

| Nitrogen | 2.6 | tons | ||

| PRTR substances | 0.1 | tons | ||

| Waste | Outsourced waste treatment | 2,838 | tons | |

| External recycling | 2,838 | tons | ||

| External landfill | 0 | tons | ||

| Waste plastics | 743 | tons | ||

| PRTR substances | 264.9 | tons | ||

| Soil condition | No emissions | |||

Kyoto Factory

The Kyoto Factory has been in operation since the company's founding.

| Location | 11-721, Honmachi, Higashiyama-ku, Kyoto |

|---|---|

| Main products | Lubricant additives, coating and adhesive products, surfactants, medical materials, etc. |

| Started operations | 1949 |

| Site area | Approx. 26,000 m² (including the Head Office and Research Laboratory) |

| ISO certification | ISO9001: obtained in 1999 |

| Employees | 109 (as of March 31, 2025) |

| INPUT | |||

|---|---|---|---|

| Energy | Energy (crude oil equivalent) |

3,745 | kL |

| Raw materials | Purchased raw materials and containers | 21,226 | tons |

| Water resources | Water withdrawal | 192 | thousand ㎥ |

| Tap water | 35 | thousand ㎥ |

|

| Industrial water | 157 | thousand ㎥ |

|

| OUTPUT to the Environment | ||||

|---|---|---|---|---|

| Global environment | GHG (CO2 equivalent) | 6,945 | tons | |

| Air quality | NOx | 1.3 | tons | |

| SOx | 0.1 | tons | ||

| Soot and dust | 0.1 | tons | ||

| PRTR substances | 0 | tons | ||

| VOC emissions | 0 | tons | ||

| Fluorocarbons (CO2 equivalent) | 13 | tons | ||

| Water quality | Water discharge | 133 | thousand ㎥ | |

| COD | 1.3 | tons | ||

| Phosphorus | 0.0 | tons | ||

| Nitrogen | 0.1 | tons | ||

| PRTR substances | 0 | tons | ||

| Waste | Outsourced waste treatment | 3,292 | tons | |

| External recycling | 46 | tons | ||

| External landfill | 0 | tons | ||

| Waste plastics | 32 | tons | ||

| PRTR substances | 71.9 | tons | ||

| Soil condition | No emissions | |||

Head Office, Head Office Research Laboratory, Katsura Research Laboratory

Our Head Office and main R&D facility. The research & development departments of SAN NOPCO LIMITED and San-Apro Ltd. are also located here.

| Location | Head Office and Head Office Research Laboratory: 11-1, Ikkyo Nomoto-cho, Higashiyama-ku, Kyoto Katsura Research Laboratory: 1-40, Goryo Ohara, Nishikyo-ku, Kyoto |

|---|---|

| On-site offices | Sanyo Chemical Industries, Ltd. Head Office, Head Office Research Laboratory, Katsura Research Laboratory, SAN NOPCO LIMITED, and San-Apro Ltd. |

| Employees | Head Office and Head Office Research Laboratory: 473, Katsura Research Laboratory: 106 (as of March 31, 2025) |

Head Office, Head Office Research Laboratory

Katsura Research Laboratory

| INPUT | |||

|---|---|---|---|

| Energy | Energy (crude oil equivalent) |

1,456 | kL |

| Water resources | Water withdrawal | 16 | thousand ㎥ |

| Tap water | 16 | thousand ㎥ |

|

| Industrial water | 0 | thousand ㎥ |

|

| OUTPUT to the Environment | ||||

|---|---|---|---|---|

| Global environment | GHG (CO2 equivalent) | 2,741 | tons | |

| Air quality | NOx | 0 | tons | |

| SOx | 0 | tons | ||

| Soot and dust | 0 | tons | ||

| PRTR substances | 0.01 | tons | ||

| VOC emissions | 0.05 | tons | ||

| Fluorocarbons (CO2 equivalent) | 8 | tons | ||

| Water quality | Water discharge | 16 | thousand ㎥ | |

| COD | 0 | tons | ||

| Phosphorus | 0 | tons | ||

| Nitrogen | 0 | tons | ||

| PRTR substances | 0 | tons | ||

| Waste | Outsourced waste treatment | 213 | tons | |

| External recycling | 143 | tons | ||

| External landfill | 0 | tons | ||

| Waste plastics | 9 | tons | ||

| PRTR substances | 5.9 | tons | ||

| Soil condition | No emissions | |||

[Domestic Subsidiaries and Affiliates]

SAN NOPCO LIMITED

In 1966, it was established as a joint venture between Nopco Chemical Company of the United States and Sanyo Chemical Industries, Ltd. of Japan. At present, it is a wholly owned subsidiary of Sanyo Chemical.

| Website | https://www.sannopco.co.jp/eng/ |

|---|---|

| Location | 31-1, Shinpomachi, Tokai, Aichi |

| Main products | Manufacture and sale of industrial agents for pulp & paper, paints, latex, ceramics, and electronics |

| Established | 1966 |

| ISO certification | ISO9001: obtained in 2000 |

| Employees | 81 (as of March 31, 2025) |

| INPUT | |||

|---|---|---|---|

| Energy | Energy (crude oil equivalent) |

1,776 | kL |

| Raw materials | Purchased raw materials and containers | 18,939 | tons |

| Water resources | Water withdrawal | 86 | thousand ㎥ |

| Tap water | 2 | thousand ㎥ |

|

| Industrial water | 85 | thousand ㎥ |

|

| OUTPUT to the Environment | ||||

|---|---|---|---|---|

| Global environment | GHG (CO2 equivalent) | 4,105 | tons | |

| Air quality | NOx | 0 | tons | |

| SOx | 0 | tons | ||

| Soot and dust | 0 | tons | ||

| PRTR substances | 0.6 | tons | ||

| VOC emissions | 1.6 | tons | ||

| Fluorocarbons (CO2 equivalent) | 1 | tons | ||

| Water quality | Water discharge | 72 | thousand ㎥ | |

| COD | 0 | tons | ||

| Phosphorus | 0 | tons | ||

| Nitrogen | 0 | tons | ||

| PRTR substances | 0 | tons | ||

| Waste | Outsourced waste treatment | 31 | tons | |

| External recycling | 5 | tons | ||

| External landfill | 0 | tons | ||

| Waste plastics | 21 | tons | ||

| PRTR substances | 3.4 | tons | ||

| Soil condition | No emissions | |||

San Chemical Co., Ltd.

Jointly established with Nippon Oil Corporation (now ENEOS Corporation) in 1982. As a specialized manufacturer of raw materials for polyurethane foam, polyethylene glycol, etc., it took over the Kawasaki Factory, the Sanyo Chemical Industries, Ltd.'s second AOA factory in Japan, which started operations in 1960.

| Website | http://www.san-chemical.com/ |

|---|---|

| Location | Head Office and Kawasaki Factory: 13-2, Chidori-cho, Kawasaki-ku, Kawasaki |

| Main products | Raw materials for polyurethane foam, raw materials for detergents, perfume and cosmetics, etc. |

| Established | 1982 |

| ISO certification | ISO9001: obtained in 2000 |

| Employees | 41 (as of March 31, 2025) |

| INPUT | |||

|---|---|---|---|

| Energy | Energy (crude oil equivalent) |

3,455 | kL |

| Raw materials | Purchased raw materials and containers | 66,001 | tons |

| Water resources | Water withdrawal | 116 | thousand ㎥ |

| Tap water | 18 | thousand ㎥ |

|

| Industrial water | 98 | thousand ㎥ |

|

| OUTPUT to the Environment | ||||

|---|---|---|---|---|

| Global environment | GHG (CO2 equivalent) | 6,843 | tons | |

| Air quality | NOx | 0 | tons | |

| SOx | 0 | tons | ||

| Soot and dust | 0 | tons | ||

| PRTR substances | 0.5 | tons | ||

| VOC emissions | 0.9 | tons | ||

| Fluorocarbons (CO2 equivalent) | 0 | tons | ||

| Water quality | Water discharge | 99 | thousand ㎥ | |

| COD | 2.1 | tons | ||

| Phosphorus | 0.0 | tons | ||

| Nitrogen | 0.2 | tons | ||

| PRTR substances | 0 | tons | ||

| Waste | Outsourced waste treatment | 1,019 | tons | |

| External recycling | 1,019 | tons | ||

| External landfill | 0 | tons | ||

| Waste plastics | 12 | tons | ||

| PRTR substances | 0 | tons | ||

| Soil condition | No emissions | |||

San-Petrochemicals Co., Ltd.

A 50:50 joint venture between Sanyo Chemical and ENEOS Materials Corporation, and a global leading specialized manufacturer of ENB.

| Website | https://www.san-petrochemicals.com/en/ |

|---|---|

| Location | 11-2, Sunayama, Kamisu, Ibaraki |

| Main products | EPDM rubber materials such as ENB (ethylidene norbornene) |

| Established | 1977 |

| Employees | 37 (as of March 31, 2025) |

| INPUT | |||

|---|---|---|---|

| Energy | Energy (crude oil equivalent) |

4,563 | kL |

| Raw materials | Purchased raw materials and containers | 11,863 | tons |

| Water resources | Water withdrawal | 48 | thousand ㎥ |

| Tap water | 3 | thousand ㎥ |

|

| Industrial water | 45 | thousand ㎥ |

|

| OUTPUT to the Environment | ||||

|---|---|---|---|---|

| Global environment | GHG (CO2 equivalent) | 7,354 | tons | |

| Air quality | NOx | 2.9 | tons | |

| SOx | 0.1 | tons | ||

| Soot and dust | 0.2 | tons | ||

| PRTR substances | 1.7 | tons | ||

| VOC emissions | 1.9 | tons | ||

| Fluorocarbons (CO2 equivalent) | 0 | tons | ||

| Water quality | Water discharge | 26 | thousand ㎥ | |

| COD | 0.3 | tons | ||

| Phosphorus | 0 | tons | ||

| Nitrogen | 0 | tons | ||

| PRTR substances | 0 | tons | ||

| Waste | Outsourced waste treatment | 41 | tons | |

| External recycling | 41 | tons | ||

| External landfill | 0 | tons | ||

| Waste plastics | 8 | tons | ||

| PRTR substances | 11.2 | tons | ||

| Soil condition | No emissions | |||

San-Apro Ltd.

| Website | https://www.san-apro.co.jp/eng/ |

|---|---|

| Location | Research laboratory: 1-40, Goryo Ohara, Nishikyo-ku, Kyoto Sales office : Tokyo |

| Lines of business | Manufacture and sale of DBU and DBN extremely strong basic organic compounds, urethane catalysts, epoxy resin curing accelerators, photo acid generators, water soluble rust inhibitors, etc. |

| Established | 1966 |

| ISO certification | ISO9001: obtained in 2003 |

| Employees | 35 (as of March 31, 2025) |

San-Apro researches, develops, and sells products specialized for catalysts. As a fabless company, it does not have an in-house production facility but commissions manufacturing to other companies, including Sanyo Chemical.

The company was established in 1966 as a joint venture with U.S.-based Abbott. Later, in 1986, the venture partner changed to U.S.-based Air Products, and the company name was changed to “San-Apro.”

In 2017, Germany-based Evonik took over the business of Air Products. At present, San-Apro is a 50:50 joint venture of Sanyo Chemical and Evonik.

Sanyo Chemical Logistics Co., Ltd.

| Location | Head Office: 31-1, Shinpomachi, Tokai, Aichi Business offices: Kyoto, Nagoya, Kashima, Kawasaki |

|---|---|

| Lines of business | Warehousing, shipping, loading and unloading in factories, and forwarding of Sanyo Chemical Group products |

| Established | 2020 |

Sanyo Chemical Logistics was established in 2020 through the merger of Nagoya Sanyo Warehouse Co., Ltd., which handled product storage and shipping as well as cargo handling on the premises for Sanyo Chemical Group, and Sanyo Transport Co., Ltd., which mainly handled the transportation of Sanyo Chemical products.

In FY2025, DHL Supply Chain will take over the Group's domestic logistics functions, which were previously handled by Sanyo Chemical Logistics Co., Ltd., with the aim of achieving efficient and sustainable logistics operations.

Shiohama Chemicals Warehouse Co., Ltd.

| Location | 2-2-6 Yako, Kawasaki-ku, Kawasaki, Kanagawa |

|---|---|

| Lines of business | Warehousing, loading, unloading, and forwarding for hazardous goods |

| Established | 1983 |

A 50:50 joint venture of Sanyo Chemical and ENEOS Materials Corporation, this warehouse company located near San Chemical Co., Ltd. handles San Chemical products.

[Overseas Subsidiaries and Affiliates]

Sanyo Kasei (Thailand) Ltd.

Sanyo Kasei (Thailand) is our base of operations in the ASEAN region.

| Website | https://www.sanyo-kasei.co.th/EN/home.html |

|---|---|

| Location | Head Office: Bangkok, Thailand Factory: Rayong, Thailand |

| Lines of business | Manufacture and sale of textile chemicals, surfactants, papermaking chemicals, paint and ink resins, etc. |

| Established | 1997 |

| ISO | ISO9001: obtained in 2004 ISO14001: obtained in 2009 |

| Employees | 93 (as of March 31, 2025) |

| INPUT | |||

|---|---|---|---|

| Energy | Energy (crude oil equivalent) |

2,278 | kL |

| Raw materials | Purchased raw materials and containers | 6,795 | tons |

| Water resources | Water withdrawal | 222 | thousand ㎥ |

| Tap water | 0 | thousand ㎥ |

|

| Industrial water | 222 | thousand ㎥ |

|

| OUTPUT to the environment | ||||

|---|---|---|---|---|

| Global environment | GHG (CO2 equivalent) | 5,091 | tons | |

| Air quality | NOx | 0.7 | tons | |

| SOx | 0.2 | tons | ||

| Soot and dust | 0 | tons | ||

| VOC emissions | 4.1 | tons | ||

| Water quality | Water discharge | 178 | thousand ㎥ | |

| COD | 30 | tons | ||

| Phosphorus | 0 | tons | ||

| Nitrogen | 2.6 | tons | ||

| Waste | Outsourced waste treatment | 3,265 | tons | |

| External recycling | 214 | tons | ||

| External landfill | 0 | tons | ||

| Soil condition | No emissions | |||

Sanyo Chemical Texas Industries, LLC

Sanyo Chemical Texas Industries is a production base for urethane beads for automobile interior parts (upholstery materials) in the United States.

| Location | Pasadena, Texas, USA |

|---|---|

| Lines of business | Manufacture of thermoplastic polyurethane beads |

| Established | 2005 |

| Employees | 10 (as of March 31, 2025) |

| INPUT | |||

|---|---|---|---|

| Energy | Energy (crude oil equivalent) |

330 | kL |

| Raw materials | Purchased raw materials and containers | 1,466 | tons |

| Water resources | Water withdrawal | 0.3 | thousand ㎥ |

| Tap water | 0.1 | thousand ㎥ |

|

| Industrial water | 0.2 | thousand ㎥ |

|

| OUTPUT to the Environment | ||||

|---|---|---|---|---|

| Global environment | GHG (CO2 equivalent) | 642 | tons | |

| Air quality | NOx | 0 | tons | |

| SOx | 0 | tons | ||

| Soot and dust | 0 | tons | ||

| Water quality | Water discharge | 1.8 | thousand ㎥ | |

| COD | 0 | tons | ||

| Phosphorus | 0 | tons | ||

| Nitrogen | 0 | tons | ||

| Waste | Outsourced waste treatment | 49 | tons | |

| External recycling | 46 | tons | ||

| External landfill | 3 | tons | ||

| Soil condition | No emissions | |||