Environmental Performance Chemicals

By offering performance chemical products that meet environmental needs, we are contributing to the realization of a sustainable society.

*Horizontally scrollable

| Areas of Contribution | Classification | Main corresponding product groups |

|---|---|---|

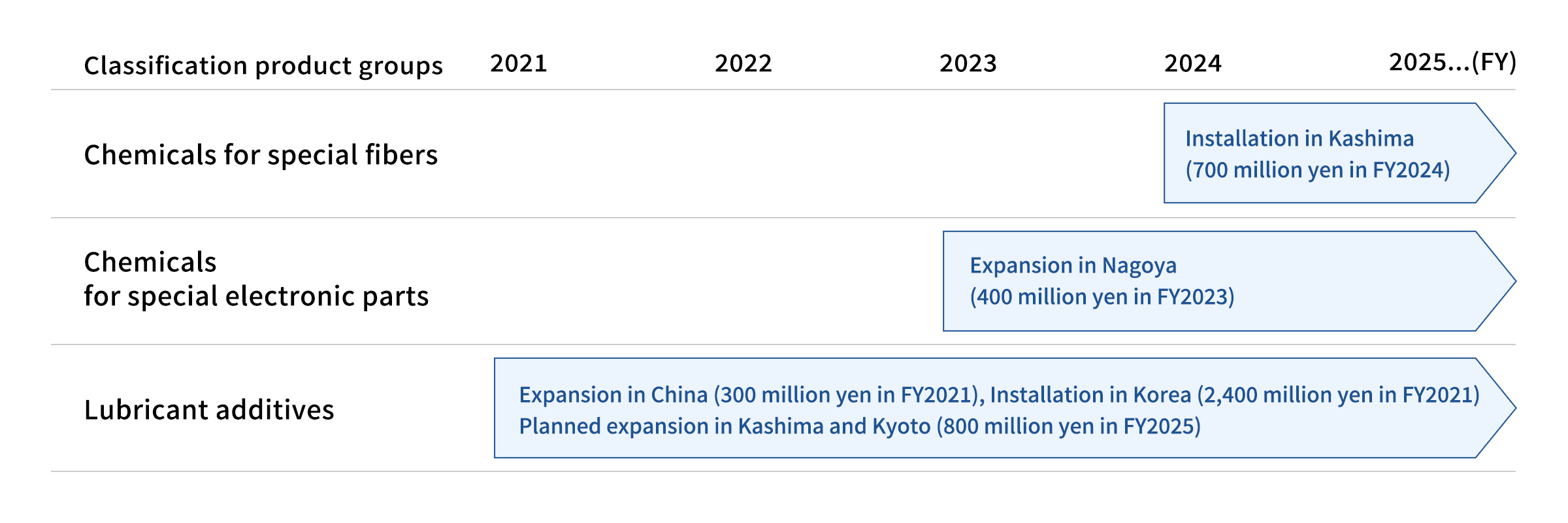

| Climate change | GHG emissions reduction | Lubricant additives, sizing agents for carbon fibers, electrolytes for aluminum electrolytic capacitors |

| Energy conservation, renewable energy | Toner resins | |

| Reduction of Environmental Impact | Water saving, removal of hazardous substances,etc. | Polymer flocculants for wastewater/sewage treatment Organic coagulants Heavy metal fixing agents for fly ash Biodegradable lubricant base |

| Air pollution prevention (VOC reduction, etc.) | Reactive hot-melt adhesive Dispersants for flue gas purification catalysts Raw materials for water-expanded (non-CFC) polyurethane foam Non-solvent type acrylic pressure-sensitive adhesives Solvent-less UV/EB curing monomers |

|

| Measures against marine pollution (including microplastics), etc. | - | |

| Waste reduction | Resin modifier | |

| Resource recycling | Utilization of reused or recycled materials | Toner resins containing recycled PET resin (Japanese only) |

| Utilization of renewable materials | A highly functional textile containing wood powder | |

| Raw materials and products for upcycling | - |

Overview of Environmental Performance Chemicals

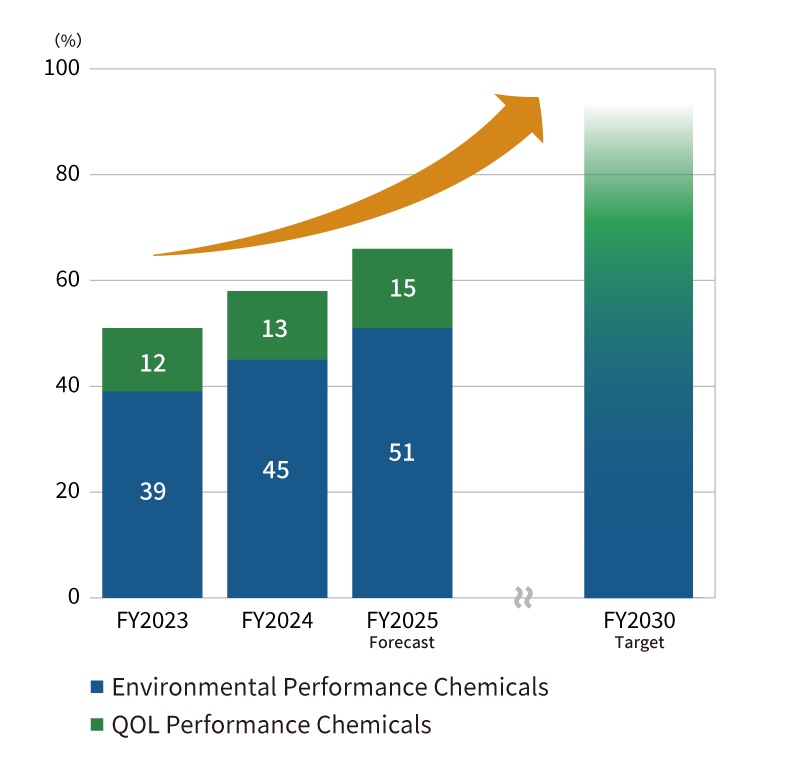

In our Medium-Term Management Plan 2025, we plan to make aggressive capital investments in products that contribute to carbon neutrality and improve quality of life, positioning them as high-value-added products.

Among these, we have defined Environmental Performance Chemicals as products and technologies that help address social issues in one of the three areas of contribution—"climate change," "reduction of environmental impact," or "resource circulation"—and have set specific targets or each.

Sales composition ratio

Capital Investment in Environmental Performance Chemicals

A New Growth Path: Creating Next-Generation Businesses

Our New Medium-Term Management Plan 2025 focuses on creating next-generation businesses that will lead to a new growth path toward 2030, with the aim of quickly commercializing them.

Carbon Recycling (CCU)

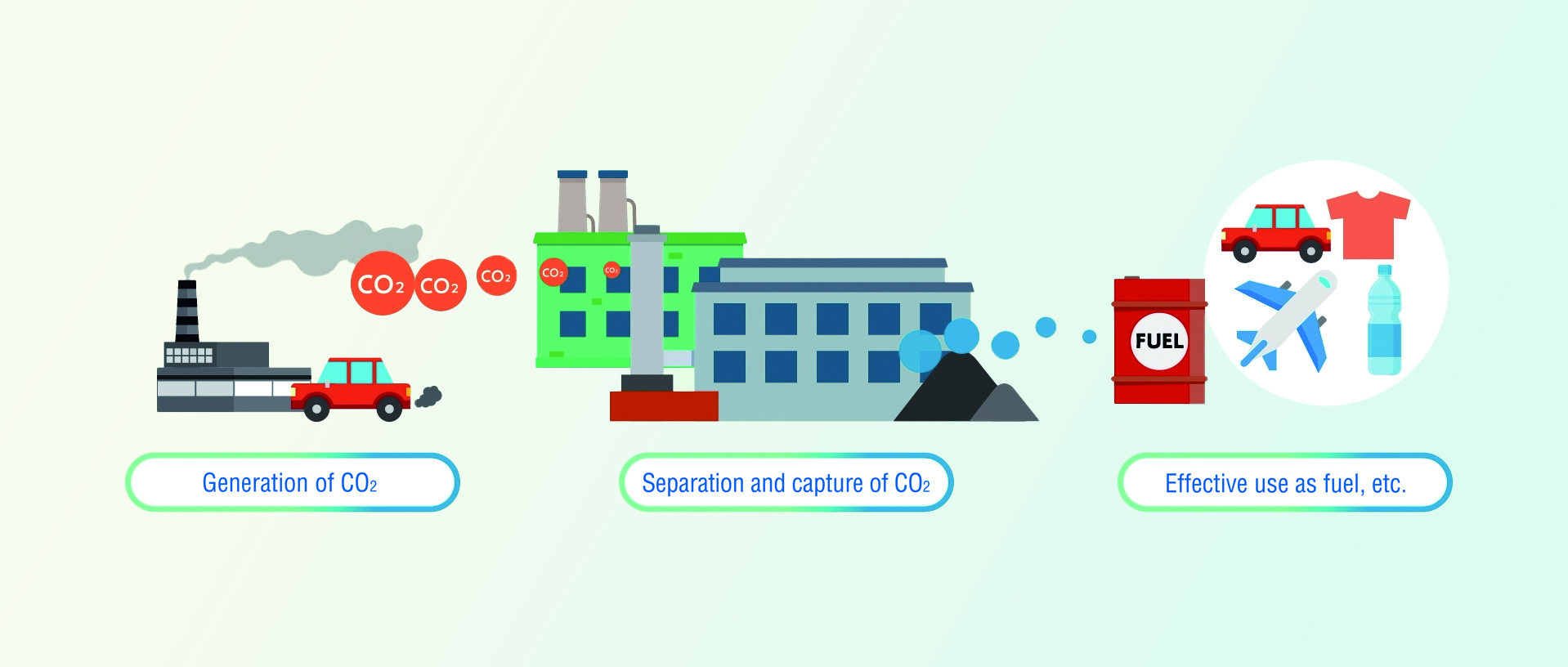

We have accumulated know-how in the design and manufacture of ionic liquids over many years through our main business of electrolytes for aluminum electrolytic capacitors. Currently, we are considering how to apply our ionic liquid technology to the systems that can efficiently capture and utilize CO2 (CCU: Carbon dioxide Capture and Utilization). CCU is expected to play a key role in sustaining the use of fossil fuels and the current industrial processes while controlling greenhouse gas emissions, which contribute to climate change. It is also expected to achieve negative emissions of CO2 when combined with renewable energy.

We aim to apply our technology to the separation of CO2 from the air, which is attracting attention as a negative emission technology, as well as from flue gas through consortium activities involving engineering partners, municipalities, and other chemical manufacturers, without being bound by the existing business framework.

CCU processes

A High-performance Textile, MOC-TEX

SAN NOPCO LIMITED, a subsidiary, has developed MOC-TEX, a high-performance textile made by upcycling unused domestic timber such as thinned wood. It has a warm, wood-like texture and a luxurious, supple feel similar to genuine leather. Containing approximately 60% to 80% bio-based aqueous polyurethane resin made in part from domestically produced wood, it contributes to achieving carbon neutrality.

Examples of products using high-performance textiles

(Usage Examples)

Headrest Cover (Japanese Only)