SANPRENE P-7315

Outline

Prepolymers for Polyurethane Elastomers, Having High Abrasion Resistance

Features

· By reacting with curing agents such as 3,3' -dichloro-4,4' -diamino diphenyl methane (MOCA), and a mixture of 1,4-butanediol and trimethylolpropane, elastomers having high abrasion resistance, high strength elastomers with excellent wear resistance and mechanical strength and low permanent strain are obtained.

· The elastomers are widely used as raw materials for elastomers for paper rolls, steel plate rolls, machine parts, belts, blades, and solid tires.

Functions

- ・Reacting/Forming

Applications

- ・Synthetic Resins & Rubbers

- ・Polyurethane Resins

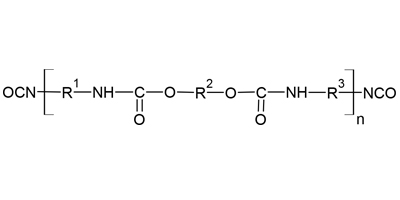

Composition

Urethane Series Polyurethane

Properties, and other information

| Principal Component | Urethane prepolymer | Appearance | Pale yellow solid | Viscosity(mPa・s) | 1,600(80℃) |

| Hardrness(Shore D, etc) | 72(Shore A) | NCO Content | 6.3 |

Precaution Against Mishandling

· Use protective eye wear, gloves and masks when handle this product, curing agents and these mixtures.

· Bubbles in this product, curing agents and these mixtures may cause defective moldings of elastomers. Prevent the bubbles from occurring or remove the bubbles from the mixtures.

· The higher the amount of the mixture, the higher the temperature because reaction heat is accumulated. As a result, pot life may also be shorten. Particularly, when large amount of ths product and curing agents are mixed in batchwise operation, the curing temperature rises too high due to the heat accumulation, and resulting elastomers may not exhibit a required physical property. Mold these mixture using molding equipment and molds which do not cause problems including heat accumulation.

Before handling this product, refer to the current Safety Data Sheet for recommended protective equipment, and detailed precautionary and hazards information.If SDS is not listed on the homepage, please contact our sales representative.