As a chemical company, the Sanyo Chemical Group handles a large number of chemical substances in its business activities. Chemical manufacturers are obligated to strive to minimize the negative impact of chemical substances by taking care of the environment, safety, and health throughout a product's entire life cycle. That includes the development, manufacture, and distribution of products, as well as the use and disposal of sold products.

Policy

Our chemical substance management regulations stipulate that we will “properly manage chemical substances handled in our business activities in consideration of their impact on the global environment, ecosystems, and human health, as well as trends in domestic and international society, and in compliance with related laws and regulations in Japan and other countries.”

This refers to all chemical substances contained in products manufactured at our facilities, the raw materials to produce them, intermediates, recovered materials, and wastes, as well as chemical structure design and process design in research and development.

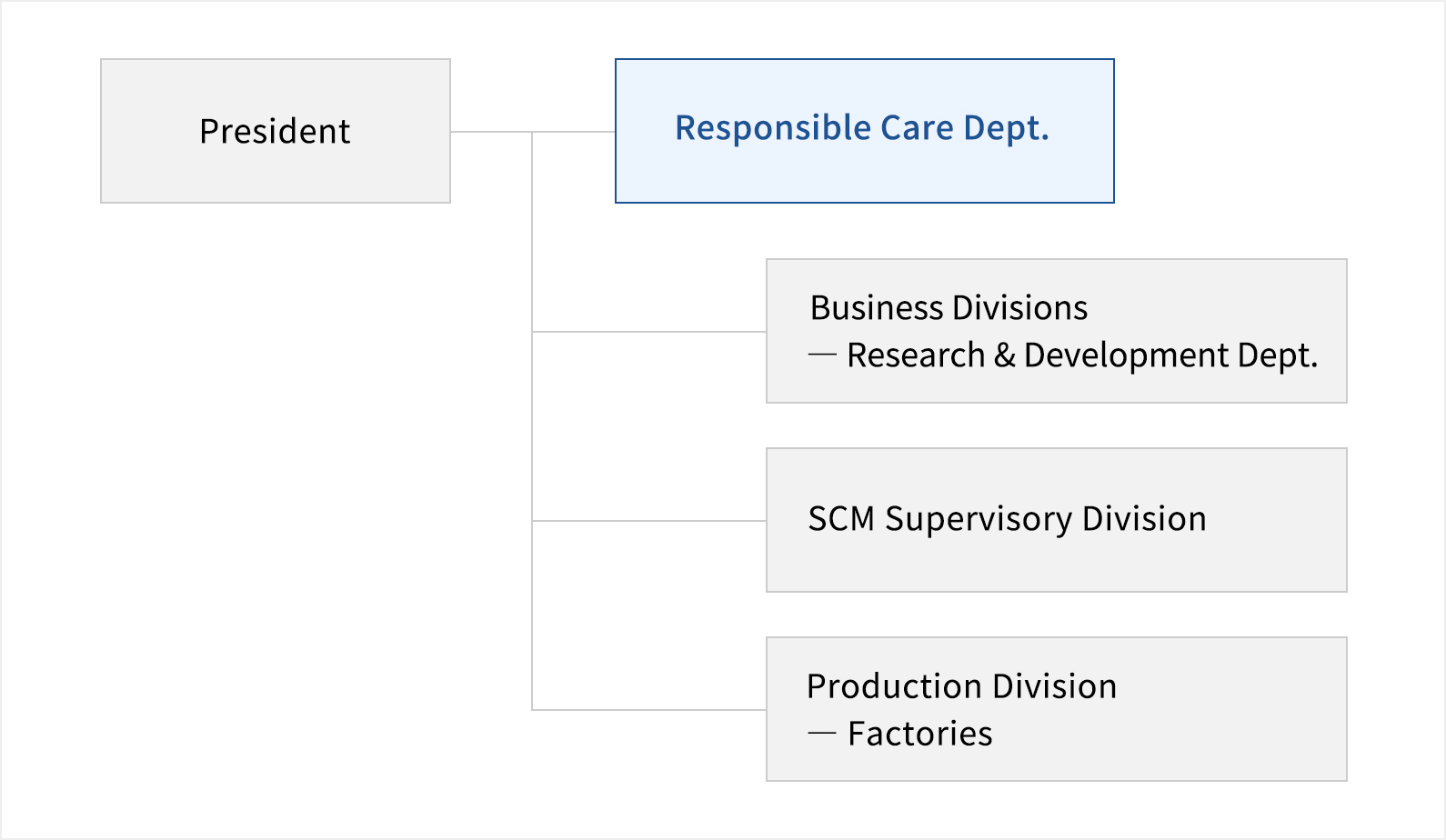

Names and Roles of Chemical Management Organizations

The General Manager of the Responsible Care Division serves as the supervisor. Respective divisions collaborate under the leadership of the General Manager to manage chemical substances.

The Production Division manages emissions to the environment arising from the handling of substances in our production activities. Design management related to the composition of manufactured products and manufacturing processes is carried out by the Production Division and the Research & Development Department that belongs to each Business Division.

*Horizontally scrollable

| Division | Primary responsibilities |

|---|---|

| Responsible Care Division |

|

| Each Business Division |

|

| SCM Supervisory Division |

|

| Production Division |

|

Safe and Appropriate Handling of Chemical Substances

As the Group handles a wide variety of chemical substances in the course of its business, knowledge of the physical properties and hazards of chemical substances is essential. For the substances we handle, we use SDS (Safety Data Sheet) to educate employees and conduct risk assessments. We encourage employees to obtain relevant qualifications for handling highly hazardous specified chemical substances, organic solvents, poisonous and deleterious substances, and hazardous materials (fire and disaster prevention measures). For example, plant engineers at our factories are required to become licensed hazardous materials engineers (Class A or B, Group 4).

Design Management

When designing products, we translate the “functions and performance” that meet customer needs into physical and chemical “properties,” and then design the chemical composition necessary to achieve those “properties.” We conduct multifaceted reviews at each stage, from prototyping to productization.

Inspections prior to launching chemical products

*Horizontally scrollable

Chemical management regulations

Customers' green procurement requirements

- Needs

- Function and performance

- Physical properties

- Chemical composition and

production processes - Trial production

- Productization

< Inspections >

Composition reviews, regulatory reviews, chemical management reviews, new raw material reviews, SDS reviews, container reviews, hazard, stability and other reviews, production facility reviews, etc.

≫ Sanyo Contributions > Supporting the Environment|Environmental Performance Chemicals

This page lists products designed with consideration given to preventing pollution and reducing polluting components based on the keywords “solvent-free,”

“halogen-free,” “free from harmful substances,” and “environmental residue reduction.”

Click here for more information about considerations regarding harmful chemical substances used for products.

The page introduces products designed by giving consideration to the prevention of pollution and reduction of content based on the keywords of “solvent-free,” “halogen-free,” “free from harmful substances,” and “environmental residue.”

Discharge Control

In order to reduce the negative impact on the air, water, and soil environment of chemical substances emitted through our production activities, we comply with laws and regulations as well as engage in voluntary emission reduction efforts.

Air Quality Conservation

Our facilities emit combustion gases (e.g., NOx, SOx) into the atmosphere due to the use of boilers, cogeneration systems, and incinerators. Our facilities also generate volatile organic compounds (VOCs) through the operation of reaction tanks and storage tanks at plants.

We endeavor to reduce the impact on air quality by maintaining and properly operating this equipment along with ancillary exhaust gas treatment equipment.

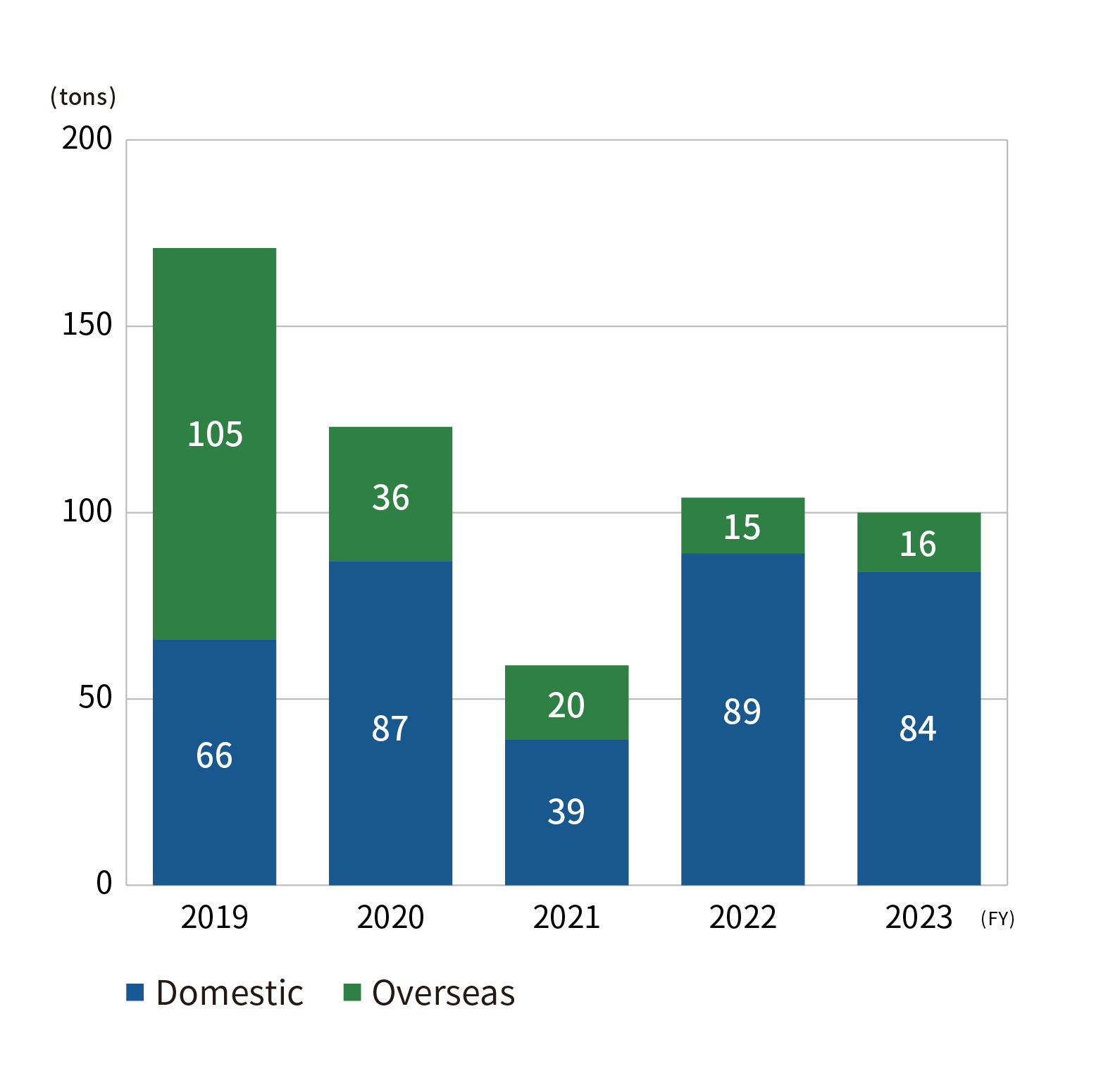

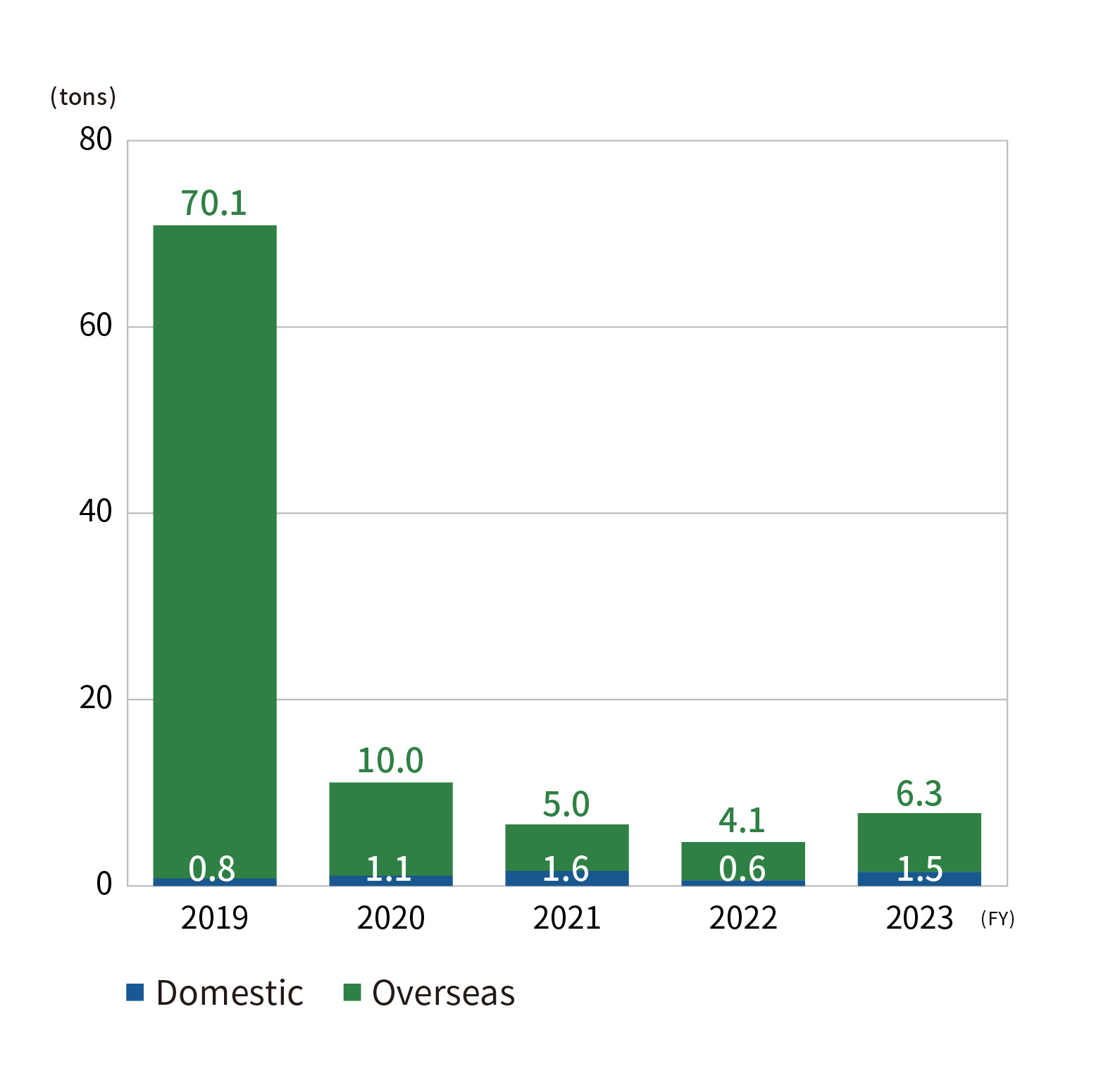

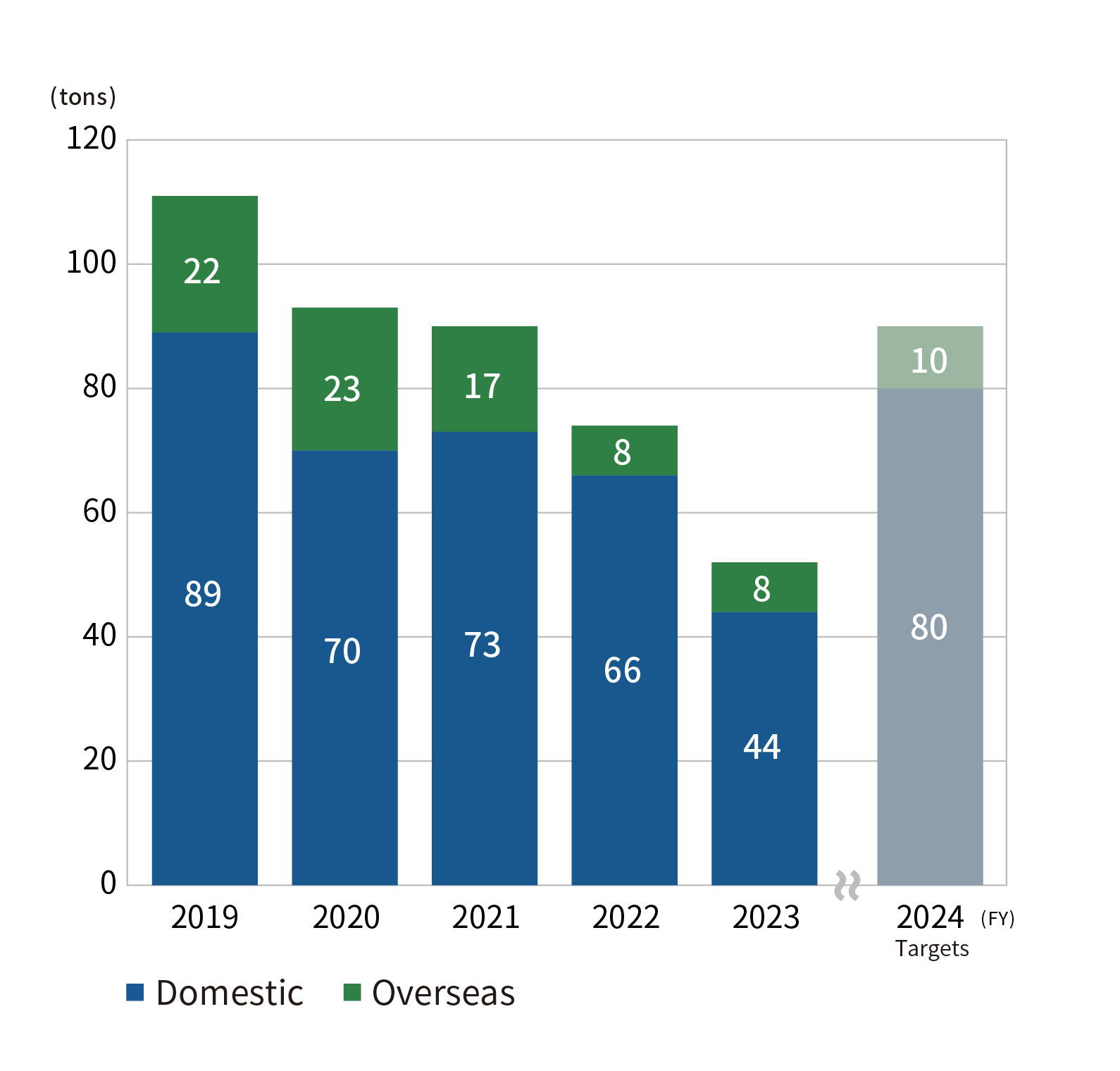

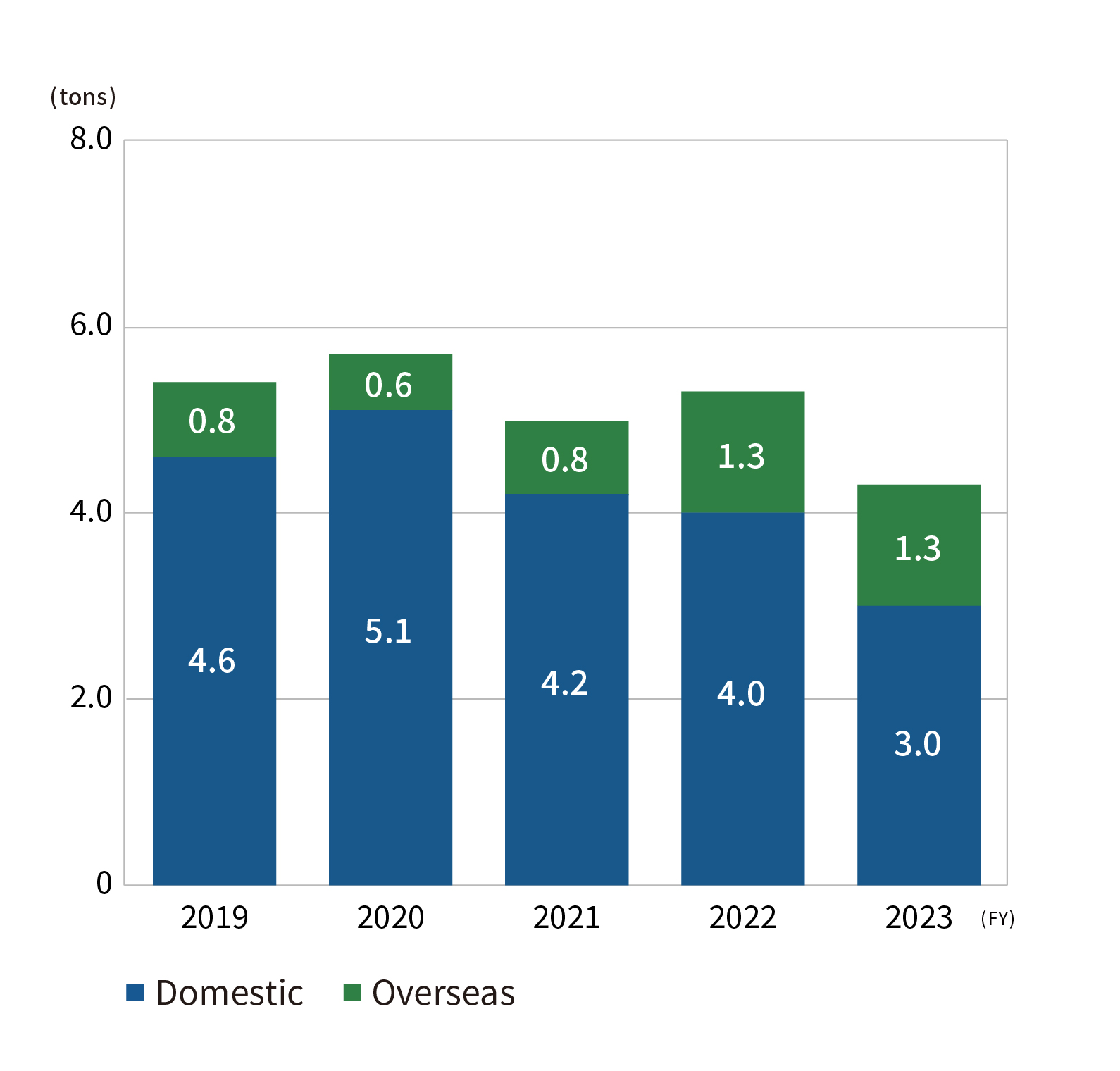

Our target for VOCs is 80 tons or less in Japan and 10 tons or less overseas by the final fiscal year (FY2024).

In FY2024, VOC emissions in Japan totaled 39 tons (down 5 tons from the previous fiscal year) and 4 tons overseas (down 3 tons from the previous fiscal year), for total Group emissions of 43 tons, achieving the FY2024 target. This is a 61% reduction from FY2019 emission volume.

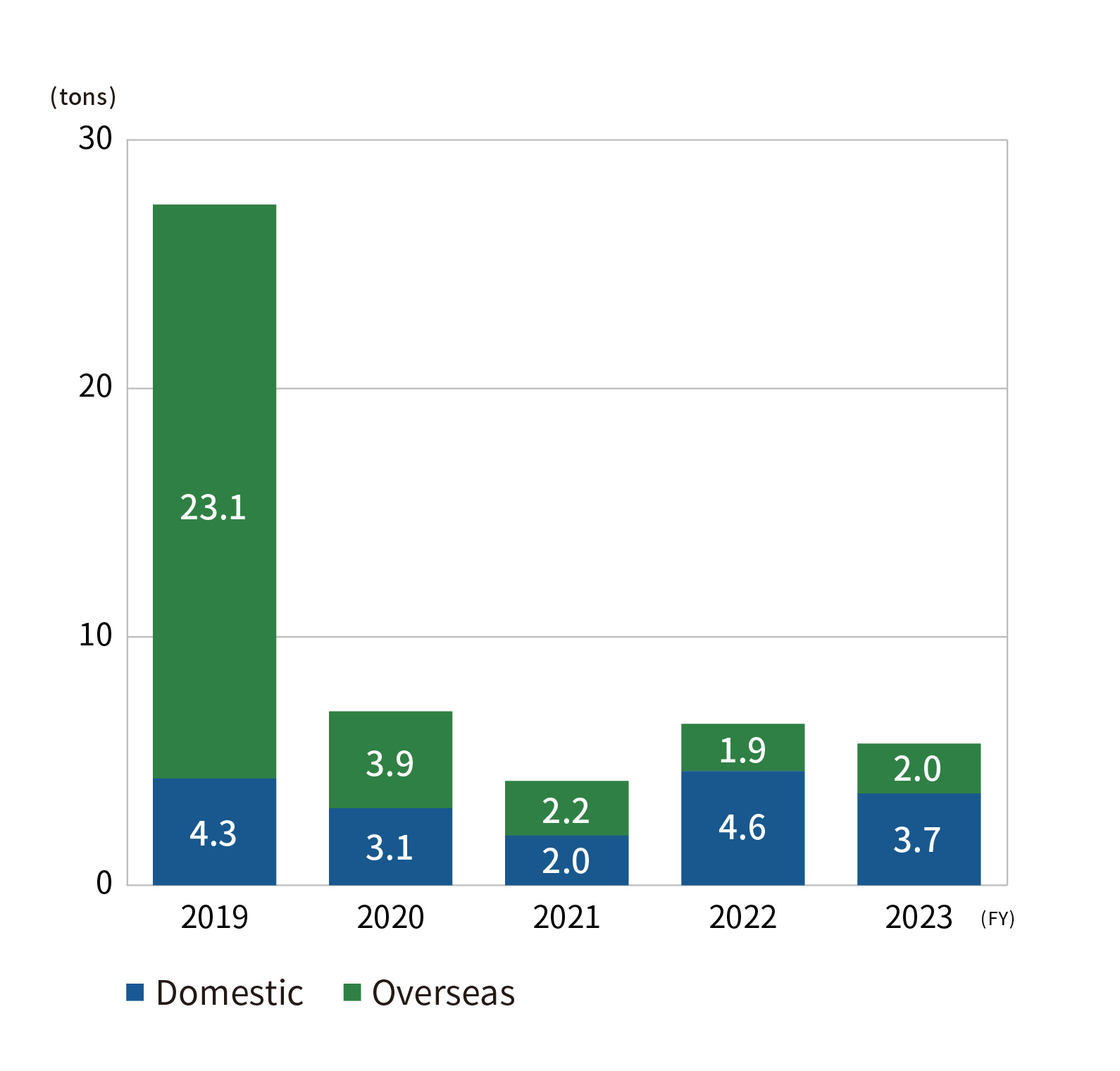

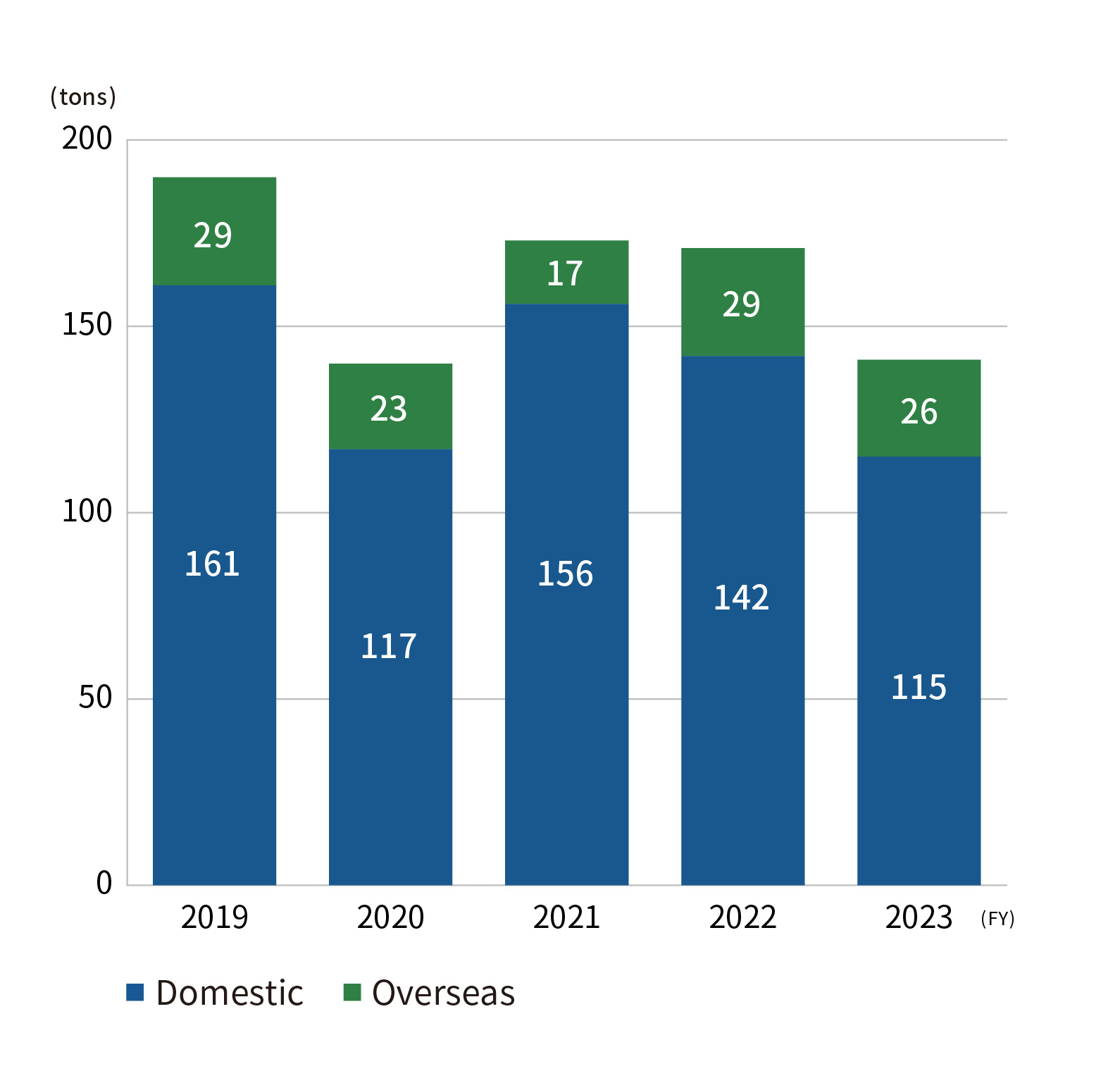

NOx emissions

SOx emissions

Soot and dust emissions

VOC emissions

- The overseas values for NOx, SOx, and soot and dust in FY2019 were high because abnormal measured values were recorded at SDP GLOBAL (MALAYSIA) SDN. BHD. Equipment and measuring methods have been reviewed, and values have been normal since FY2020.

- Scope of VOC calculation: All facilities in Japan, as well as Sanyo Kasei (Thailand) Ltd.

Water Quality Conservation

For the wastewater discharged from the pipes at our facilities, we set voluntary control values that are stricter than the legal effluent control values, and monitor the status of the wastewater to control pollutant concentrations. We endeavor to prevent the discharge of pollutants into aqueous environments by appropriately maintaining equipment, installing containment dikes, and taking measures to prevent leakages at facilities.

≫ ESG Data > Environment | Water Resource Related Data

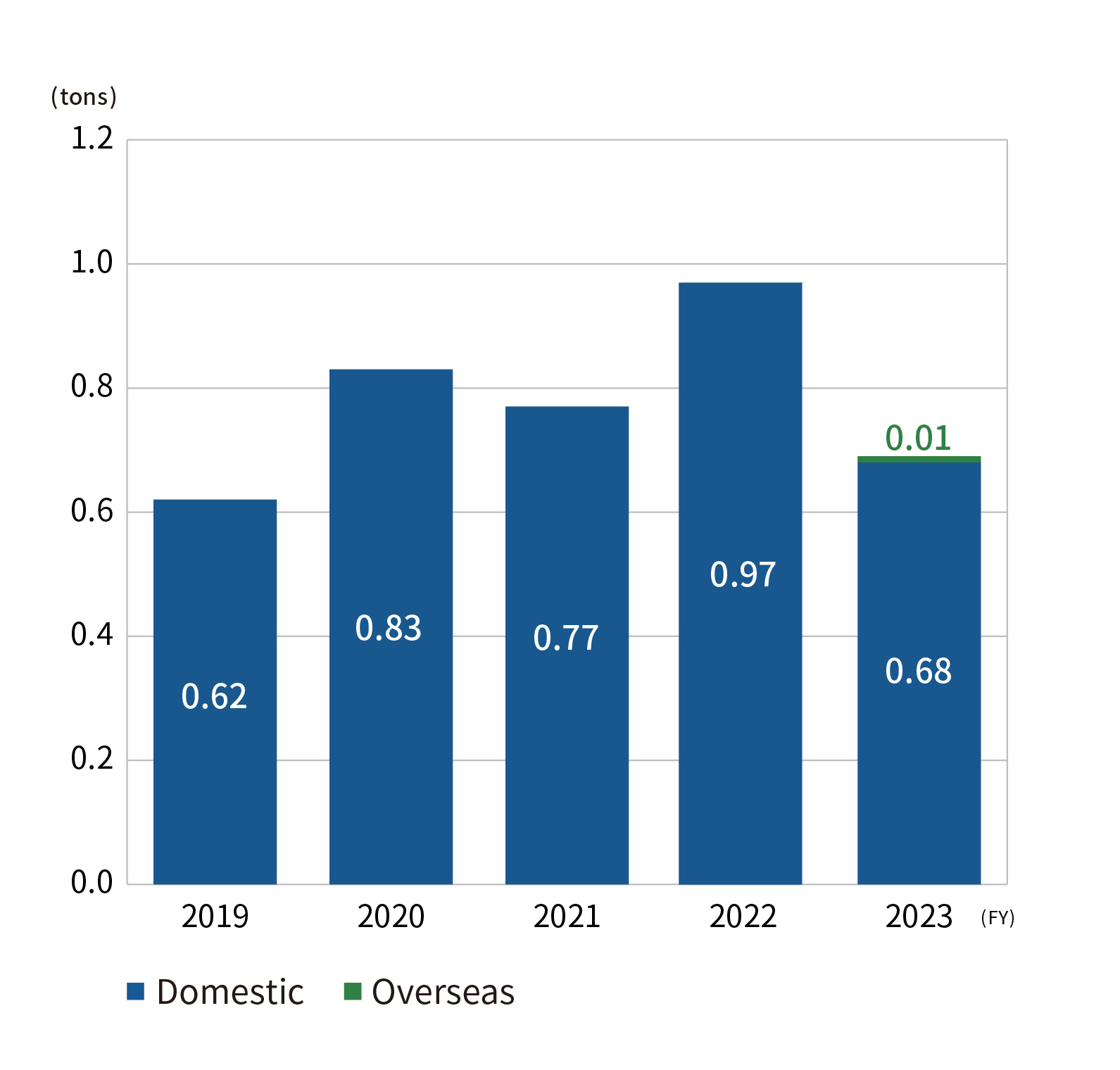

COD

Total phosphorus emissions

Total nitrogen emissions

Soil and Groundwater Environmental Conservation

We do not perform landfill disposal at facilities. Along with monitoring the condition of groundwater using observation wells at facilities, we conduct voluntary soil surveys on company premises during construction work to check for problems on an ongoing basis.

Compliance with PRTR Law

In addition to substances subject to the PRTR Law, we monitor emissions of VOCs not subject to the Law from our facilities and prioritize them in our efforts to reduce emissions.

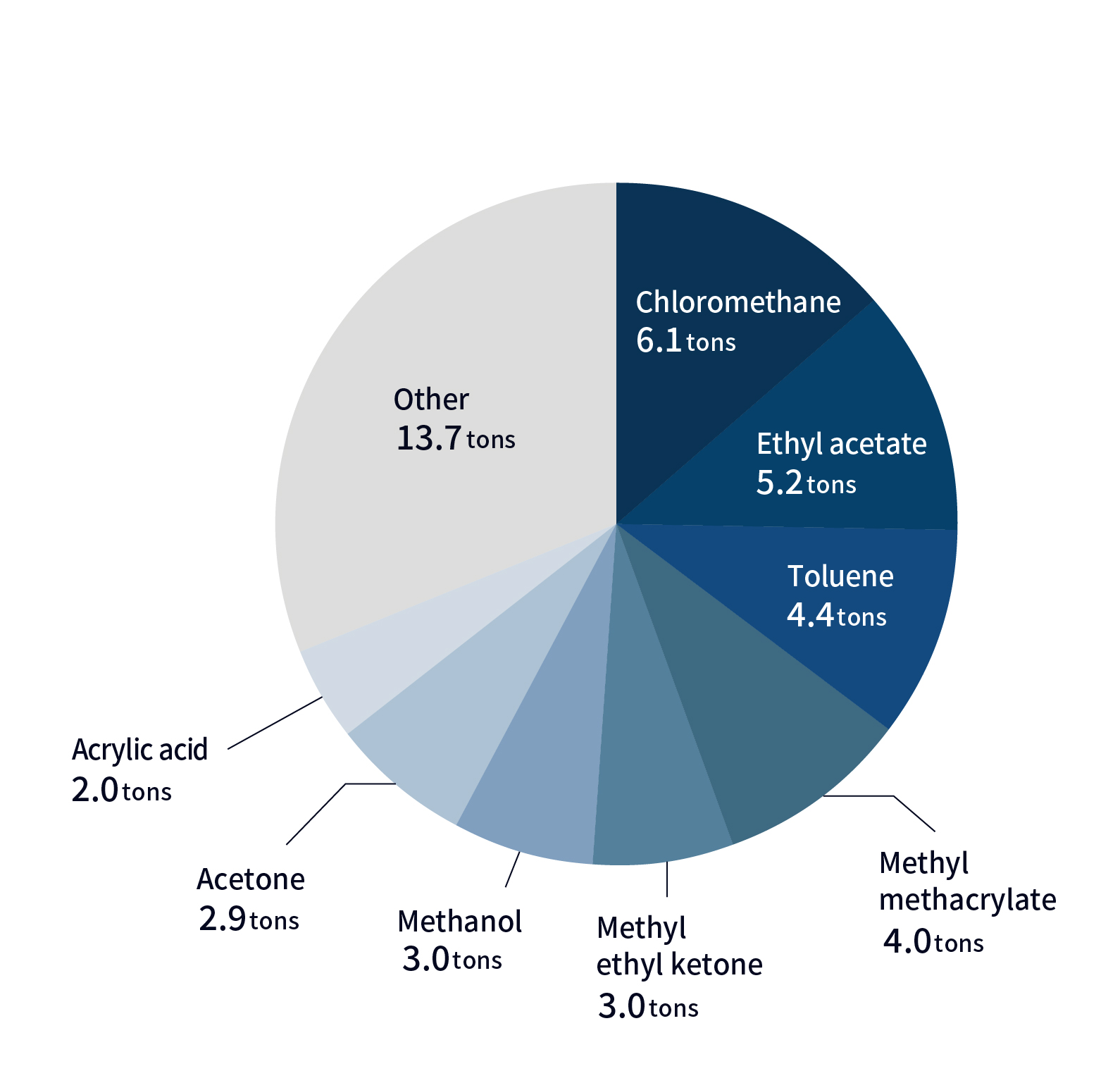

From FY2022 to FY2023, we took measures to reduce emissions of chloromethane, which had the highest emission volume among domestically emitted VOCs but for which no effective countermeasures had been in place.

Through manufacturing process improvements, we succeeded in reducing our previously excessive input of chloromethane, reducing chloromethane emissions from 17.2 tons in FY2021 to 4.2 tons in FY2024.

Overseas, we will incorporate emission reduction technologies developed in Japan to reduce emissions through combustion and adsorption treatment of exhaust gases.

Breakdown of VOCs (FY2024, domestic)

Release and Transfer of Substances Subject to the PRTR Law (FY2024)

(Unit: tons)

*Horizontally scrollable

| Substances handled | Volume handled | Atmospheric emissions | Water emissions | Soil emissions | Waste transferred | |

|---|---|---|---|---|---|---|

| Sanyo Chemical | 99 | 115,839 | 20.8 | 0.5 | 0 | 432.0 |

| Domestic subsidiaries and affiliates | 56 | 93,421 | 3.5 | 0 | 0 | 14.6 |

| Total | 113 | 209,260 | 24.3 | 0.5 | 0 | 446.6 |