As a chemical manufacturer, the Sanyo Chemical Group's mission is to provide products that customers can be confident about using. To this end, we believe it is important to guarantee quality by designing for safety at the design stage and manufacturing products under reliable quality control.

Policy

“Throughout the entire product lifecycle ranging from product development through manufacturing and use to disposal, we will implement product safety measures with top priority placed on safety and conduct strictly product management. We will also provide appropriate information and faithfully respond to inquiries and complaints.”

Quality Assurance, Quality Control, and Product Liability (PL)

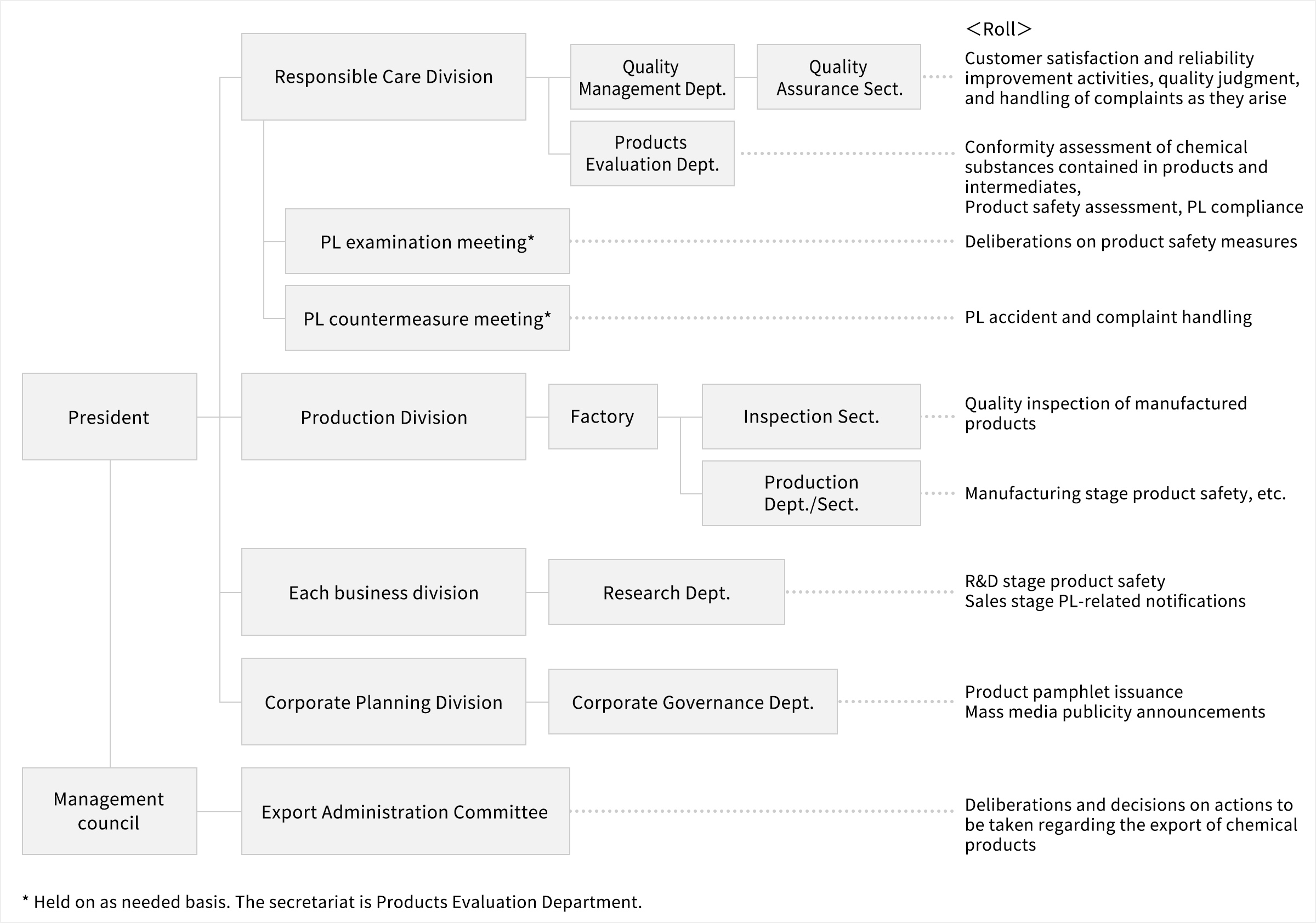

Products produced in the Production Division are tested and inspected by the Inspection Sect. within the Division, and quality determination is made by the Quality Assurance Sect., which is part of the Responsible Care Division and which has staff stationed at each factory.

We have also obtained ISO9001 certification for our domestic and overseas factories, and have established and are operating a quality control system that is synergistic with our quality control system.

When a complaint is received or non-conforming product is found at a plant, the Quality Assurance Sect. cooperates with plant personnel to investigate the cause, formulate sweeping countermeasures to prevent recurrence, and share the information with Group factories to replicate those countermeasures.

The Products Evaluation Dept. of the Responsible Care Division is a department that specializes in product liability (PL), and conducts product compliance reviews with domestic and international laws and regulations, label and safety data sheet (SDS) reviews, voluntary management of chemical substances, and customer services.

In the event of PL-related deliberations, accidents or complaints, we will convene an investigative meeting and a countermeasure meeting to deal with them accordingly.

In FY2023, there were no PL-related deliberations, accidents, or complaints.

Organization

*Horizontally scrollable

Provision of safe and secure products

Through communication with customers, we ascertain their needs with regard to performance, quality, and the environment, and we introduce products and develop new products that meet these needs. We also disseminate appropriate technical and safety information on our products through press releases, press conferences, and exhibitions.

We begin selling new products only after we understand their applications at the customer's site and confirm that they conform to the customer's requirements for green procurement and nonuse of conflict minerals. We also stipulate that chemical substances which meet customers' needs be selected at the product design stage.

≫ Product information

≫ Resins & functional chemicals website

Export Control

The export of chemical products may be restricted due to the Export Trade Control Order in Japan, laws/regulations of destination countries, or international treaties. In order to observe those rules, we have incorporated an export stop system in our order system. When making entry of an order, the system rejects products not registered in our export control database. Products Evaluation Department closely examines and inputs information into the database serving as the foundation of this system, such as product chemical compositions and their status in other countries and any restrictions imposed by any laws or regulations. The Export Administration Committee discusses and examines our group’s compliance to laws and regulations in concerned countries and then implements changes as necessary.

Product Safety

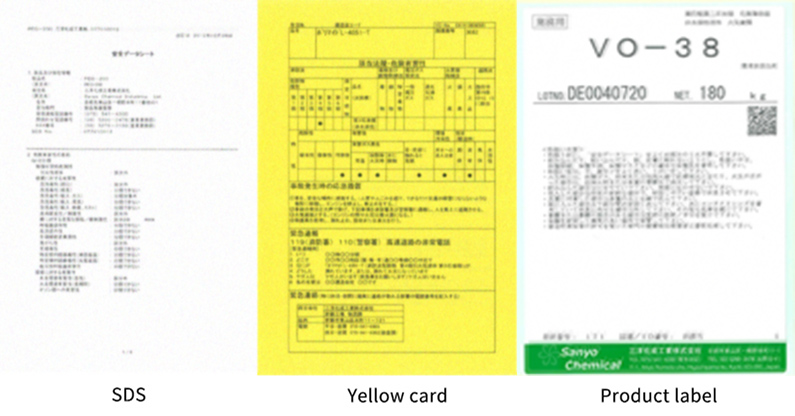

At the product design stage, we design compositions that exclude prohibited substances stipulated by our chemical substance management regulations, as well as prohibited and restricted substances/substances to be reduced that are stipulated by our customers’ green procurement standards. After confirming that the designed composition complies with domestic and international laws and regulations and undergoing a safety data sheet (SDS) and label review, we commercialize the relevant products.

When we introduce our product sample, we also submit the SDS at the same time so that the customer can check the technical features and the safe handling methods.

Following the revision of laws related to chemical substances, including the Chemical Substance Control Law, Industrial Safety and Health Act, PRTR Law, and Poisonous and Deleterious Substances Control Act, we revised the SDS and product label accordingly.

To each driver of trucks and tanker trucks that transport our products, we issue a yellow card with first-aid methods and emergency contact information so that they can appropriately respond in case of an accident during transportation.

≫ Environment > Chemical Substance Management|Design Management

≫ Product Information|Safety Data Sheet (SDS)