Artificial Protein Silk-Elastin

Damage and deformation of cartilage and meniscus can lead to knee osteoarthritis, which in turn increases the risk of decreased motor function and affects the locomotive syndrome. Since it has become clear that meniscus repair and regeneration is important for the complete cure of knee joint diseases, the number of meniscal suture surgeries is increasing. However, since the meniscus is difficult to repair once damaged, about 30% of the three million suture surgeries performed annually worldwide result in insufficient healing and the risk of re-rupture.

Silk-Elastin for meniscus regeneration applications

Against this background, a research group at Hiroshima University has conducted joint research with the concept of an ultimate cure, using our Silk-Elastin to regenerate both the knee cartilage and the meniscus.

Silk-Elastin is an artificial protein created using gene recombination technology introduced by us. Featuring a high affinity with human cells, it creates an environment for cell proliferation that promotes the repair and regeneration of biological tissues. Its efficacy and safety were confirmed in physician-initiated clinical trials, with a comment from the investigator stating that the results were astonishing.

Silk-Elastin for wound healing applications

In the fields of chronic wounds (e.g., diabetic foot ulcers) and acute wounds (e.g., burns), a joint research project with Kyoto University has completed physician-initiated clinical trials for wounds that were not expected to heal with conventional treatments, with favorable results obtained in corporate clinical trials. We therefore plan to obtain regulatory approval in FY2024 and start sales in FY2025.

Expected market and future potential

The global market for Silk-Elastin for meniscus regeneration applications is expected to be worth over 100 billion yen, with the U.S. accounting for more than half of this total. For wounds, (bedsores, and burns), due to its wound healing ability and ease of handling, we aim to replace competitive medical devices (artificial dermis, NPWT*) with Silk-Elastin.

With strong advantages such as excellent healing ability and shortened healing time, Silk-Elastin has a wide range of uses and applications. We promote 10 or more research topics, including muscle regeneration applications. We plan to first establish a track record in wound healing applications, and then develop Silk-Elastin into a pillar of our business by 2030 for meniscus regeneration applications, for which there is a large market.

- Negative pressure wound therapy

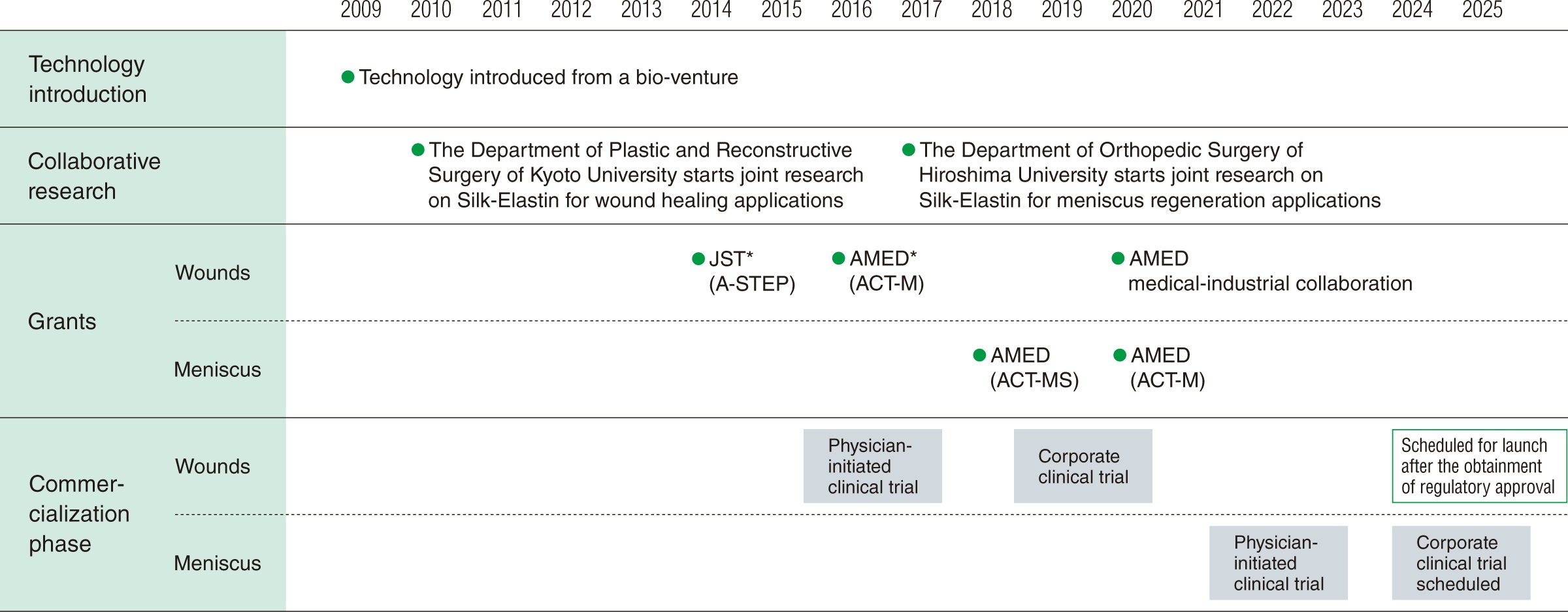

Silk-Elastin Development History

*Horizontally scrollable

- JST: Japan Science and Technology Agency

- AMED: Japan Agency for Medical Research and Development

Toward Building a Sustainable Agricultural System

In Japan, the aging of agricultural workers and a shortage of successors are becoming apparent, while the world is facing major issues such as the reduction of chemical fertilizers and pesticides, greenhouse gas emissions, and water and soil contamination. We aim to provide solutions to agricultural issues using interface control technology and other chemical technologies we have cultivated over the years.

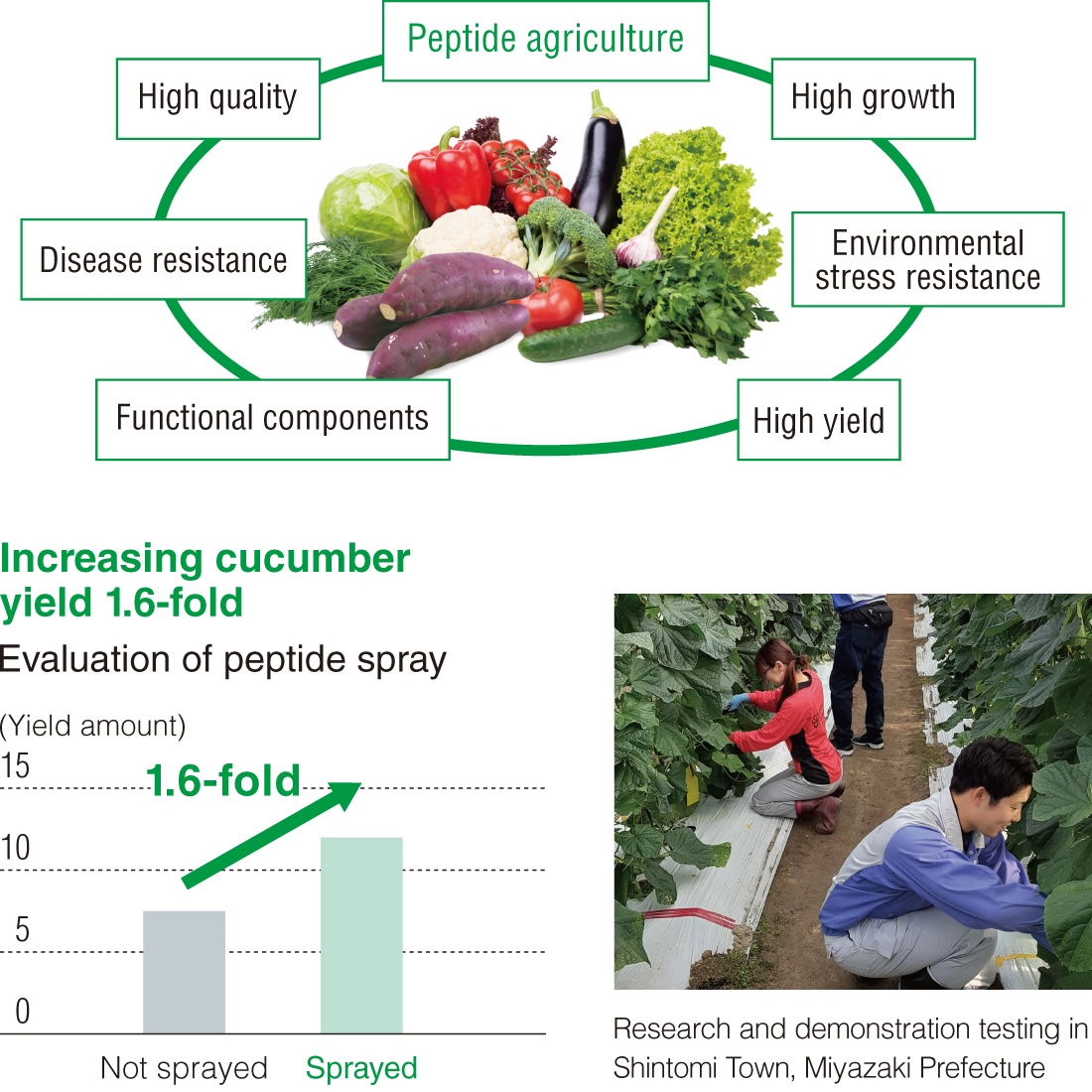

Peptide agriculture

We are involved in R&D on peptides* for agriculture that allow plants to express properties they naturally lack, and that can bring out various plant functions more easily and safely than with conventional breeding. By improving plant resistance to stress caused by climate change and other factors, the yield and quality of agricultural crops are expected to improve. We will actively establish new peptide agriculture and provide agricultural support.

- Peptides play a key role in plant metabolism and information transmission between tissues, and are essential components for adapting to the growing environment and improving resistance.

*Horizontally scrollable

Electronic Nose

Humans use their five senses to collect information, grasp a situation, and make judgments. However, indicators based on these senses face issues such as lack of data reliability and reproducibility, as well as difficulty in data sharing and storage. Of the five senses, a sensor that visualizes olfaction has been the least developed due to the wide variety of odorants and the complex mechanisms used in detecting odors.

Launch of the electric nose “FlavoTone”

In November 2023, we launched “FlavoTone” an electric nose that can visualize complex and diverse odors using a mechanism similar to human olfaction. Since it can visualize both specific odors and complex odors, it offers solutions such as odor-based quality control, characteristic comparison, and monitoring.

It is also equipped with an application that uses machine learning to analyze the obtained data, enabling output tailored to needs and applications, such as quality control, characteristic comparison, and monitoring.

The FlavoTone Business Promotion Dept. has received inquiries about joint research from various parties, and we aim to achieve an operating profit of 1 billion yen by 2030.

“FlavoTone” Type-A

“FlavoTone” Type-G