Policy

As a chemical manufacturer, Sanyo Chemical Group is committed to contributing to the carbon neutrality of society as a whole, not only by reducing GHG emissions from its own facilities, but also by developing and providing product lines that help reducing CO2 emissions. At the same time, we are actively undertaking energy conservation efforts through various measures to reduce energy consumption.

Targets and Results

We were able to achieve our targets for FY2024, the final fiscal year of Environmental Action Plan 21-24

Medium- to Long-Term GHG (Scope 1, Scope 2) Emissions Reduction Targets

*Horizontally scrollable

| FY | Group targets (CO2 equivalent) | Notes |

|---|---|---|

| 2013 | 309 thousand tons | Base year |

| 2030 | 154 thousand tons | Interim target (halved comparing to base year) |

| 2050 | Carbon Neutral | Final target |

Environmental Action Plan 21-24

*Horizontally scrollable

| Themes | FY2019 (base year) results | FY2020 | FY2021 | FY2022 | FY2023 | FY2024 target |

FY2024 | Assessment |

|---|---|---|---|---|---|---|---|---|

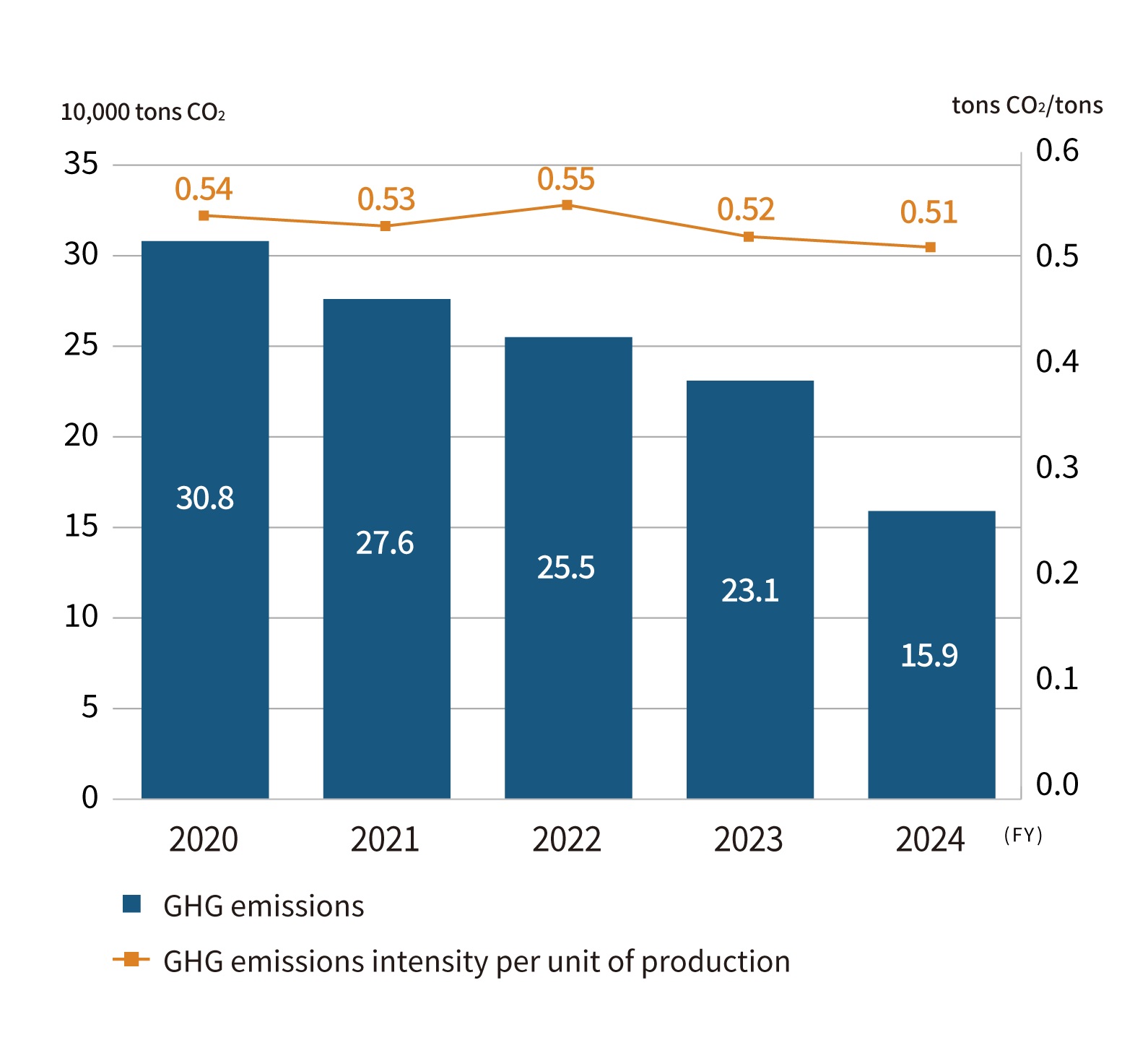

| GHG emissions (10,000 tons) |

31.1 Domestic: 17.6 Overseas: 13.5 |

30.8 Domestic: 15.7 Overseas: 15.1 |

27.6 Domestic: 15.3 Overseas: 12.3 |

25.5 Domestic: 14.6 Overseas: 10.9 |

23.1 Domestic: 12.3 Overseas: 10.8 |

29.5 or less | 15.9 Domestic: 10.6 Overseas: 5.3 |

Achieved |

| Percentage reduction (compared to FY2019) |

- | 1% | 11% | 18% | 26% | 5% or above | 49% | |

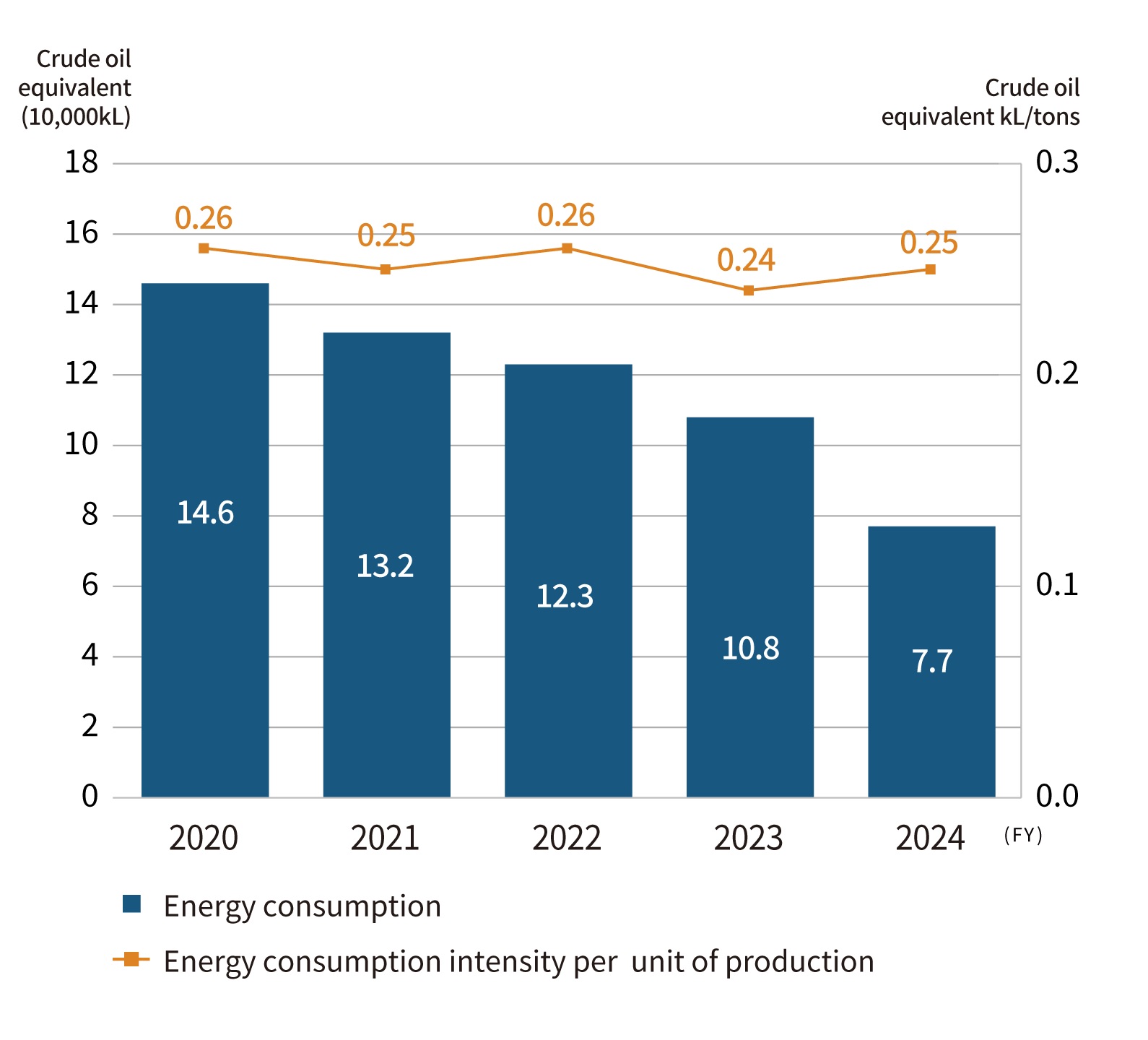

| Energy consumption in crude oil equivalent (10,000 kL) |

14.7 Domestic: 9.0 Overseas: 5.7 |

14.6 Domestic: 8.1 Overseas: 6.5 |

13.2 Domestic: 8.1 Overseas: 5.1 |

12.3 Domestic: 7.8 Overseas: 4.5 |

10.8 Domestic: 6.5 Overseas: 4.3 |

14.0 or less | 7.7 Domestic: 5.7 Overseas: 2.0 |

Achieved |

| Percentage reduction (compared to FY2019) |

- | 1% | 10% | 16% | 27% | 5% or above | 48% |

Scope: All of the Sanyo Chemical facilities, all of the domestic subsidiaries & affiliates, and overseas subsidiaries & affiliates that have production bases*

- Sanyo Chemical Texas Industries, LLC; Sanyo Kasei (Thailand) Ltd., San-Dia Polymers (Nantong) Co., Ltd.

Energy consumption and intensity

GHG emissions (Scope 1, Scope 2) and intensity

In FY2024, the Group as a whole reduced its energy consumption in crude oil equivalent to 77,000 kL (57,000 kL domestically and 20,000 kL overseas) through reduced production and the implementation of energy-saving and CO2 emission reduction measures, a decrease to 52% compared to FY2019. For the same reason, GHG emissions in CO2 equivalent also came to 159,000 tons (106,000 tons domestically and 53,000 tons overseas), a decrease to 51% relative to FY2019.

GHG Emissions

*Horizontally scrollable

| Emission/absorption/ reduction contribution classification |

GHG type | Volume (CO2 equivalent) |

||

|---|---|---|---|---|

| FY2022 | FY2024 | |||

| Environmental impact | Emission | Direct emissions from fuel oil combustion at facilities (Scope 1) | 105 thousand tons | 69thousand tons |

| Methane (generated from septic tanks) | 30 tons | 24 tons | ||

| Nitrous oxide (byproduct of combustion) | 156 tons | 113 tons | ||

| Other GHG (NF3, PFC, SF6) | No emissions | No emissions | ||

| CFC leakage from chillers and others | 241 tons | 157 tons | ||

| Indirect emissions from the use of electricity, heat, or steam purchased at facilities (Scope 2) (market basis) | 126 thousand tons | 89 thousand tons | ||

| Supply chain emissions (Scope 3) | 1,911 thousand tons | 1,755 thousand tons | ||

| Impact reduction | Absorption | Increase in forest CO2 absorption (due to tree thinning project) | 20 tons | 13 tons |

| Reduction contribution | CO2 reduction by users using our products that contribute to reducing CO2 emissions | 540 thousand tons | 900 thousand tons* | |

- Target products were reviewed in FY2024. For details, see ≫ Supporting the Environment | Environmental Performance Chemicals

The GHG emitted from our facilities other than CO2 consist of methane from septic tanks, nitrous oxide as a combustion byproduct, and CFCs leaked from chillers and other equipment, etc. in FY2024 (294 tons of CO2 equivalent in total). These non-CO2 GHG emissions are negligible at 0.22% of Scope 1, Scope 2 emissions, with CO2 emissions accounting for almost all supply chain emissions, including Scope 3 emissions.

Fluorocarbons

Our domestic facilities own approximately 800 commercial air conditioners and chillers that use fluorocarbons. These units require equipment inspections and reporting of the volume of fluorocarbons leaked, and we conduct these inspections every year according to the Fluorocarbon Emissions Control Act. Total fluorocarbon leakage volume in FY2024 was 82 kg (including 0 kg of ozone-depleting fluorocarbons), which is equivalent to 157 tons of CO2 as a GHG. This is a decrease of 84 tons year on year.

In June 2025, we received the highest rating of A from the Japan Refrigerants and Environment Conservation Organization (JRECO) for our initiatives under the Fluorocarbon Emissions Control Act.

Measures to Achieve Carbon Neutrality

Since most of the GHG emitted from our Group's facilities is CO2, we seek to achieve carbon neutrality throughout the supply chain by focusing on efficient energy usage by building and operating an energy management system and energy conversion (fossil fuels to solar power and hydrogen) for Scope 1, Scope 2 emissions; on the use of low-GHG raw materials (bio-based materials and other raw materials that contribute to carbon neutrality) for Scope 3 emissions; on energy-saving effects, reduction of GHG emissions, and resource saving effects when using our products; and on developing technologies for CCU (Carbon Dioxide Capture and Utilization). The New Medium-Term Management Plan calls for implementing a “Monozukuri Transformation,” a series of business process reforms throughout the supply chain that will involve digital transformation (DX). This effort will involve promoting initiatives that lead to carbon neutrality, such as a fundamental re-examination of production processes and the use of low-GHG raw materials.

Products made with bio-based materials

Bio-based materials are increasingly replacing petrochemical feedstock as a more renewable and sustainable material. For its part, Sanyo Chemical Group has developed raw materials for sunscreen formulations derived from rice bran and a highly functional textile containing wood powder. We will continue to develop bio-based high-performance products that contribute to reducing our environmental impact.

Installation of solar panels at Sanyo Kasei (Thailand) Ltd.'s factory

Sanyo Kasei (Thailand) Ltd. has completed a ground-mounted solar power plant project in collaboration with an electric power company. It provides 5,000 square meters of land for the installation of solar panels, with a total generation capacity of 889 kW. Grid connection (power transmission) was made began on December 1, 2024.

Supported Initiatives

*Horizontally scrollable

| Initiative | Sponsoring organization |

|---|---|

| TCFD | Task Force on Climate-related Financial Disclosures |

| Challenge Zero | Keidanren (Japan Business Federation) |

| GX League | Ministry of Economy, Trade and Industry |

| Kyoto's Challenge to Net-Zero by 2050 | Kyoto City |