As a member of the Responsible Care Committee of the Japan Chemical Industry Association (former the Japan Responsible Care Council), Sanyo Chemical Group has established a Management Policies Concerning Responsible Care (RC) and conducts RC activities. We are also engaged in environmental management efforts in line with an Environmental Action Plan that includes priority actions and targets.

≫ Management Policies Concerning Responsible Care (RC)

Policy

The policy adds “We will strive for perfection in safety and harmony with the environment, which is the first required mission in the society” to our Company Mission and “We shall proactively take initiatives to conserve the environment and prevent accidents and disasters as crucial requirements for the sustainability and activity of our business” to our Code of Corporate Ethics.

We are also taking concrete actions in line with our CSR Guidelines, which call for reducing environmental impact, realizing the sustainable global environment and improving convenience and comfort as a focus of product development, and conducting sustainable purchasing.

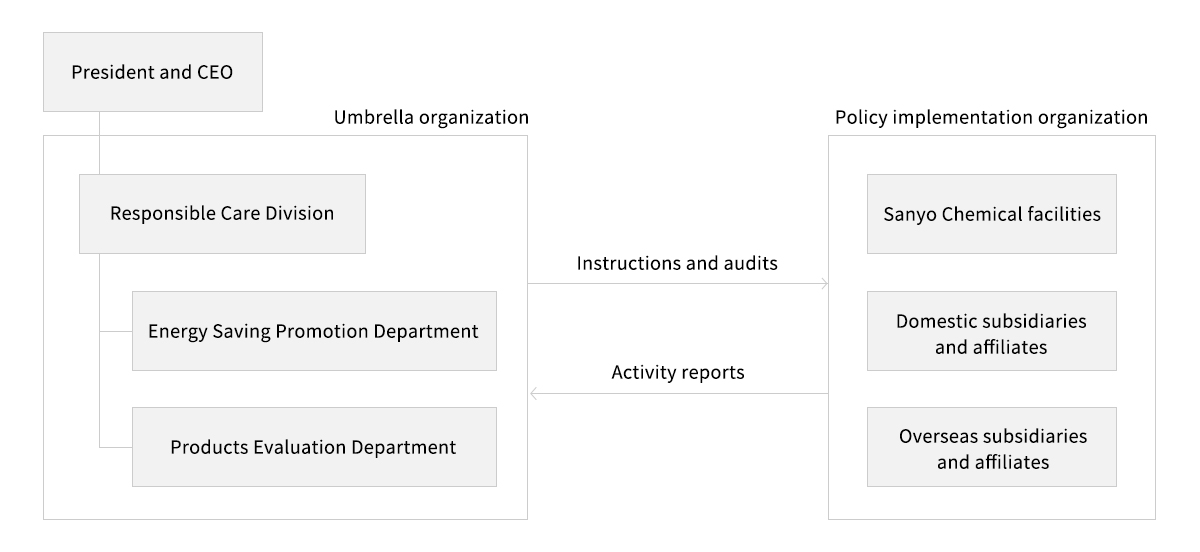

Management System

*Horizontally scrollable

The Responsible Care Dept. of the Responsible Care Division oversees all environmental conservation activities, while the Products Evaluation Dept. is in charge of chemical and product safety activities and certain logistics safety activities. We had used the environmental management system (ISO14001) as a tool for RC activities promotion. However, as the Company has internally established a system to build a management system according to ISO requirements and continuously promote improvements, we have determined that we can operate the system sufficiently on our own, and we relinquished ISO14001 certification for all of our domestic facilities in FY2020. For our overseas facilities, we continue to maintain ISO14001 certification. In addition, our quality management system (ISO9001) has been certified both in Japan and overseas (San-Petrochemicals Co., Ltd. also relinquished its ISO9001 certification in FY2020).

We will also continue our safety, health, environment, and security audits of domestic and overseas factories and laboratories, which are conducted during annual site visits (remote audits are conducted for certain overseas sites).

Environmental Action Plan

Environmental Action Plan 21-24

*Horizontally scrollable

| Themes | FY2019 (base year) results | FY2024 results | FY2024 (final year) targets | Assessment | |

|---|---|---|---|---|---|

| Targets | Reduction rate target compared to base year | ||||

| (1) GHG emissions (10,000 tons) |

31.1 Domestic: 17.6 Overseas: 13.5 |

15.9 Domestic: 10.6 Overseas: 5.3 |

29.5 or less | 5% or above | Achieved |

| (2) Energy consumption (10,000 kL) |

14.7 Domestic: 9.0 Overseas: 5.7 |

7.7 Domestic: 5.7 Overseas: 2.0 |

14.0 or less | 5% or above | Achieved |

| (3) Water consumption (1,000 ㎥) |

4,354 | 3,732 | 4,136 or less | 5% or above | Achieved |

| (4) Waste generated (10,000 tons) |

4.8 | 3.2 | 3.6 or less | - | Achieved |

| (5) VOC*1 emissions (tons) | 112 Domestic: 89 Overseas: 22 |

43 Domestic: 39 Overseas: 4 |

90 or less Domestic: 80 or less Overseas: 10 or less |

19.7% or above | Achieved |

- VOC: Total atmospheric emission of substances subject to the PRTR Law, and PRTR substances specified by the Japan Chemical Industry Association

Scope: All of Sanyo Chemical facilities , all of the domestic subsidiaries & affiliates, and overseas subsidiaries & affiliates that have production bases*2

- 2 Sanyo Chemical Texas Industries, LLC; Sanyo Kasei (Thailand) Ltd.; San-Dia Polymers (Nantong) Co., Ltd.

Environmental Action Plan 25-29

Environmental Action Plan 21-24 has been completed, and all targets for FY2024 have been achieved.

We have set themes and targets for Environmental Action Plan 25-29, which covers FY2025 to FY2029.

Energy targets have been revised from total consumption to energy consumption per unit, to drive further improvements in energy efficiency.

*Horizontally scrollable

| Themes | FY2024 (base year) results | FY2025 targets | FY2029 targets | Notes |

|---|---|---|---|---|

| (1)Improvement of energy consumption per unit | ― | 1% decrease | 5% decrease | Energy consumption per unit of production |

| (2) Reduction of CO2 emissions (10,000 tons) | 15.9(10.7)*2 Domestic: 10.6 Overseas: 5.3 |

11.2 or less | 10.7 or less | Set based on production volume plan |

| (3) Reduction of water usage (1,000 m3) | 3,730(3,480)*2 Domestic: 3,290 Overseas: 440 |

3,430 or less | 3,290 or less | 1% annual decrease |

| (4) Reduction of waste generated (10,000 tons) | 3.2(3.1)*2 | 3.1 or less | 2.9 or less | - |

| (5) VOC*1 emissions (tons) | 43 Domestic: 39 Overseas: 4 |

43 or less | 43 or less | FY2024 result or less |

- VOC: Total atmospheric emission of substances subject to the PRTR Law, and PRTR substances specified by the Japan Chemical Industry Association

- Figures in parentheses are actual values for FY2024, excluding the superabsorbent polymer business, from which the Company withdrew in 2024.

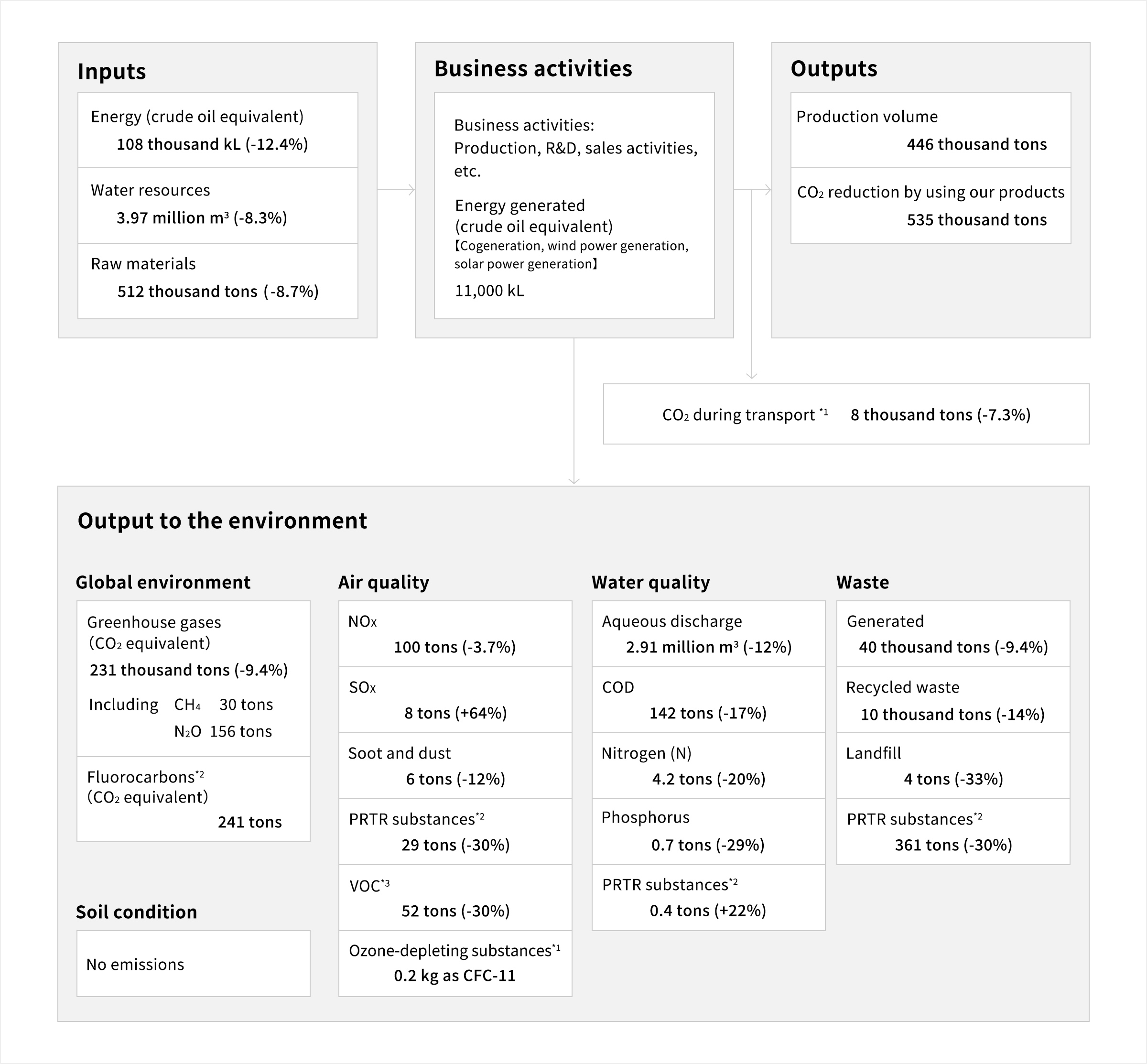

Environmental Impact Overview

FY2024 Material Flow

Figures in parentheses indicate the percentage change from the previous year.

*Horizontally scrollable

Unless noted, the values shown below are consolidated results for all domestic and overseas facilities

- Total domestic transport of all Sanyo Chemical facilities, SDP Global Co., Ltd., and SAN NOPCO LIMITED

- Total of all Sanyo Chemical facilities and all domestic affiliates/subsidiaries

- Total of all Sanyo Chemical facilities plus domestic affiliates/subsidiaries; Sanyo Kasei (Thailand) Ltd., and San-Dia Polymers (Nantong) Co., Ltd.

Environmental Management Indicators

Environmental Accounting (April 1, 2024 to March 31, 2025)

-

Total of all Sanyo Chemical facilities; all domestic affiliates/subsidiaries; Sanyo Chemical Texas Industries, LLC; Sanyo Kasei (Thailand) Ltd.; San-Dia Polymers (Nantong) Co., Ltd.

However, Sanyo Kasei (Thailand) Ltd. uses a fiscal year from January 1, 2024 to December 31, 2024, the same as its reporting period.

Environmental Conservation Investments and Expenses

[Classification according

to business activity]

(Unit: million yen)

| Classification | Investment*1 | Expenses*2 | |

|---|---|---|---|

| Facility area expenses | (1) Pollution prevention expenses | 235 | 841 |

| (2) Global environment conservation expenses | 65 | 549 | |

| (3) Resource circulation expenses | 0.4 | 1,202 | |

| Upstream/downstream expenses | 0 | 35 | |

| Administrative expenses | 0 | 346 | |

| R&D expenses | 0 | 2,331 | |

| Social activity expenses | 0 | 191 | |

| Environmental remediation expenses | 0 | 0.2 | |

| Total | 301 | 5,495 | |

- Investment amounts are based on receiving inspections for the period in question

- Expense amounts include depreciation

[Classification according to environmental conservation measures]

(Unit: million yen)

| Classification | Investment | Expenses |

|---|---|---|

| (1) Global warming measures | 65 | 546 |

| (2) Ozone layer protection measures | 0 | 4 |

| (3) Air-quality conservation measures | 153 | 393 |

| (4) Noise and vibration measures | 0 | 65 |

| (5) Environmental conservation measures for the aquatic, ground, and geologic environments | 82 | 399 |

| (6) Waste and recycling measures | 0.4 | 1,204 |

| (7) Measures for reducing chemical risk and emissions | 0 | 222 |

| (8) Natural environment conservation | 0 | 12 |

| (9) Other | 1.1 | 318 |

| Total | 301 | 3,163 |

- R&D expenses are not classified

[Economic impact of environmental conservation measures (monetary units)]

(Unit: million yen)

*Horizontally scrollable

| Impact | Amount | Main items | |

|---|---|---|---|

| Energy saving | 105 | Reduction in purchase of electricity and steam by using waste heat and cogeneration, etc. | |

| Resource saving | Waste reduction | 78 | Reduction in resource consumption and waste generation via process improvements |

| Raw material use reduction (yield improvement) | 52 | Increase in product yield and reduction in process chemicals | |

| Revenue from recycling | 63 | Income on sale of waste solvents, used containers, etc. | |

| Total | 296 | ||

- Includes effects of non-investment measures (e.g., process improvements)

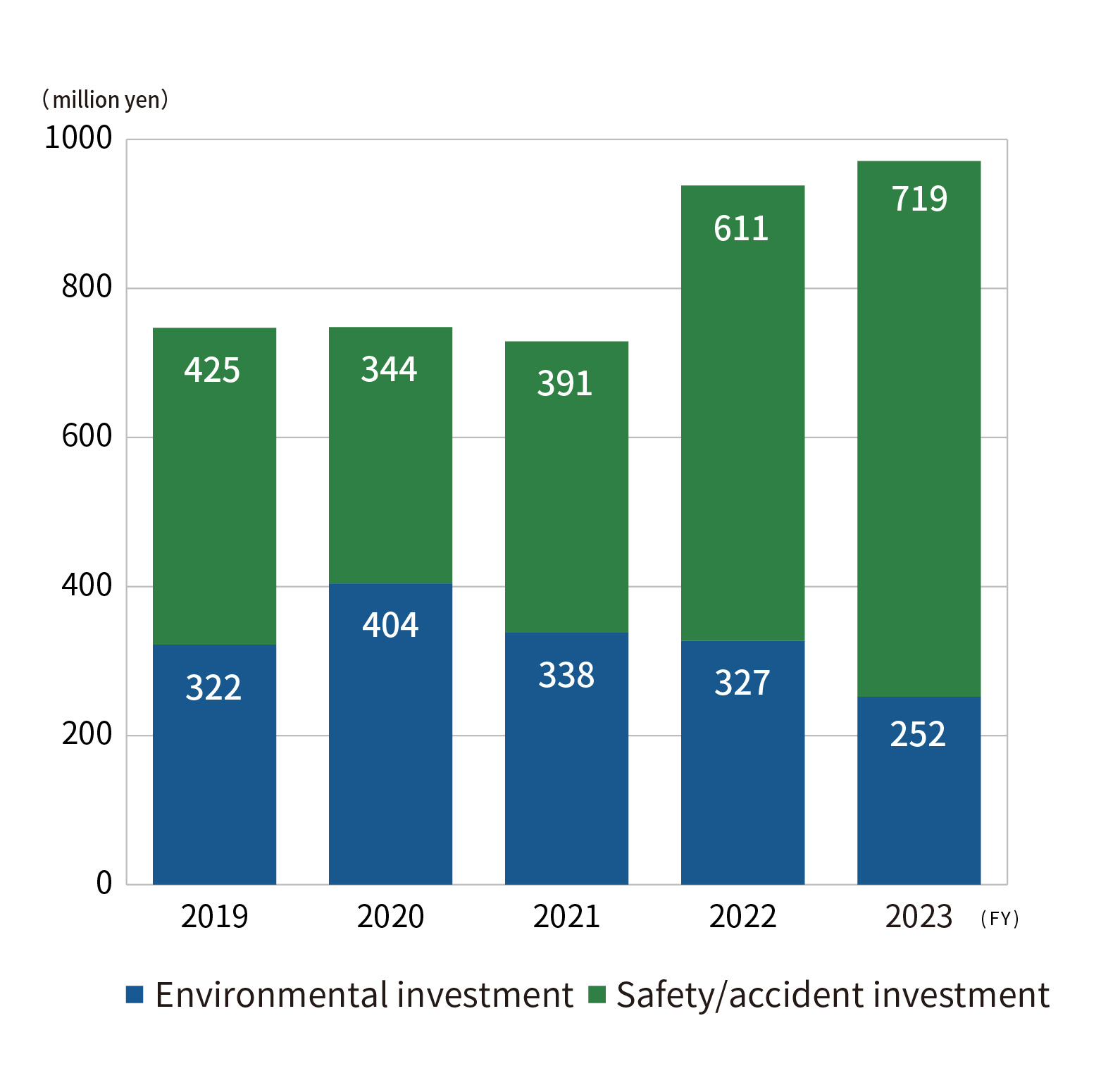

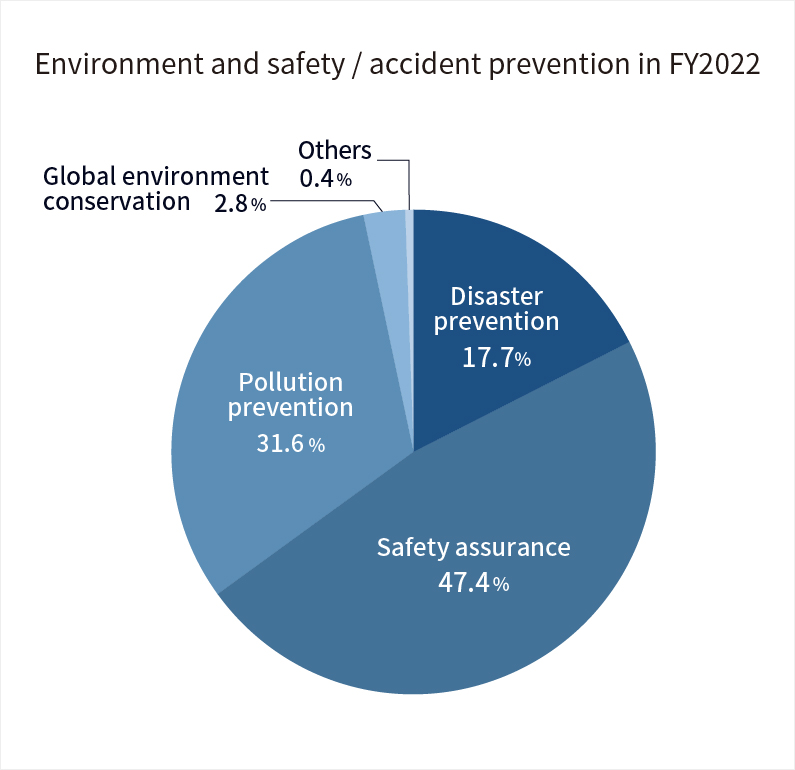

Environment, Safety, and Accident Prevention Investment

To conserve the environment and ensure safety, we continue to invest in environmental measures as well as in safety and disaster prevention, including industrial accident prevention, earthquake countermeasures, and 3Ds (Dirty, Dangerous, and Demanding jobs) improvements.

In FY2024, environmental investment totaled 301 million yen and safety/accident prevention investment was 636 million yen.

Environment, safety, and accident prevention investment

Breakdown of environment and safety/

accident prevention investment in FY2024

Compliance Regarding Environmental Matters

There were no pollution complaints, violations of environmental laws or regulations, administrative guidance, and lawsuits at our domestic facilities in FY2024.