Promoting Environmental Conservation and Safety Through Responsible Care

Practicing Environmental Management

While endeavoring to develop environmentally-friendly products, Sanyo Chemical continues to actively promote Responsible Care (RC) activities, in environmental conservation, ensuring safety and accident prevention as well. Sanyo Chemical places a great deal of importance on environmental conservation, occupational safety and product stewardship. We aim to live with society and to be in harmony with the environment through environmental management by adhering to the principles of RC.

Creating Model Plants for Performance Chemicals

All Factories in Japan Obtained ISO 9001 Certification

Sanyo Chemical factories in Nagoya, kinuura, Kyoto and Kashima obtained ISO 9001, a product quality certificate issued by the International Organization for Standardization.

With the aim to create model plants for performance chemicals, Sanyo Chemical is continuing to promote automation with our engineering workers constructing more unique and advanced production systems.

Nagoya Factory

The Nagoya Factory has the largest production capacity for us, located in a coastal industrial zone in South Nagoya. Products manufactured at this facility include polyurethane chemicals, base materials for electronic materials and surfactants.

Operation Date: 1968

Area: approx. 100,000 m2

Kinuura Factory

The Kinuura Factory has been producing alkylene oxide adducts (AOAs, raw materials for polyurethane foams, etc.) since October 2010.

Operation Date: 2010

Area: approx. 140,000 m2

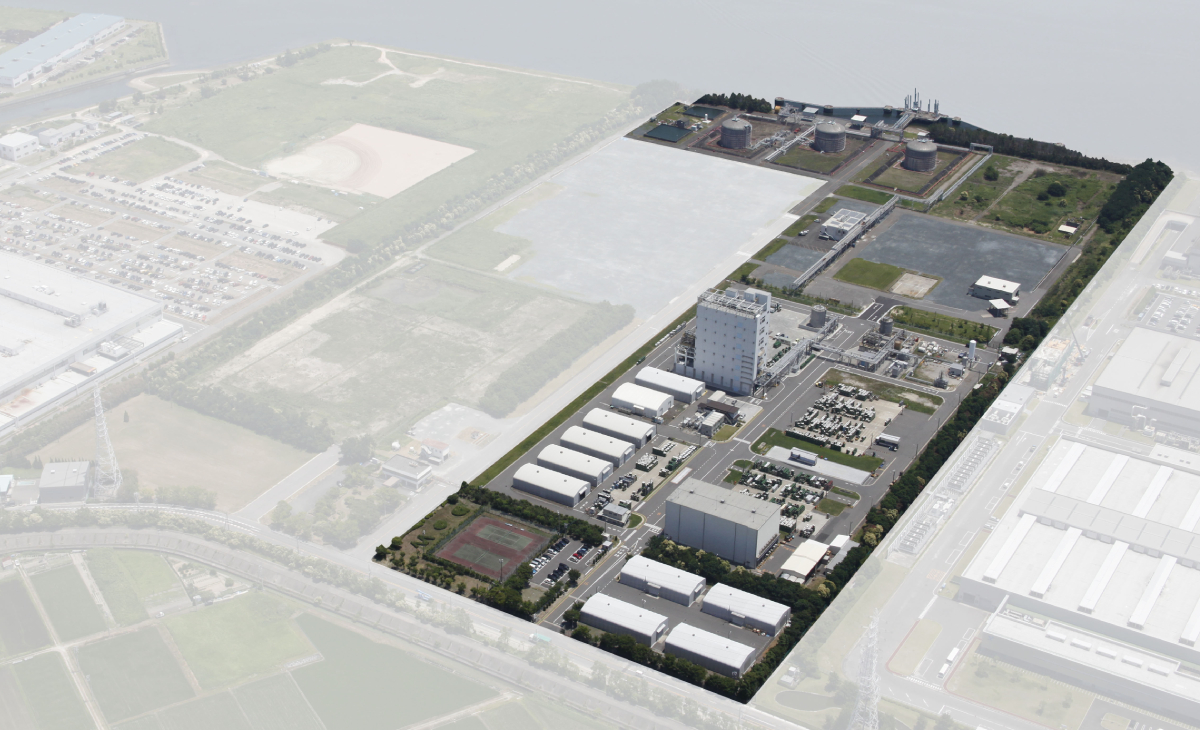

Kashima Factory

The Kashima Factory located in Ibaraki Prefecture has Sanyo Chemical’s principal production and distribution facility in the Kanto area. This factory is responsible for the manufacture of products such as toner resins, lubricant additives, and water-soluble polymers.

Operation Date: 1976

Area: approx. 130,000 m2

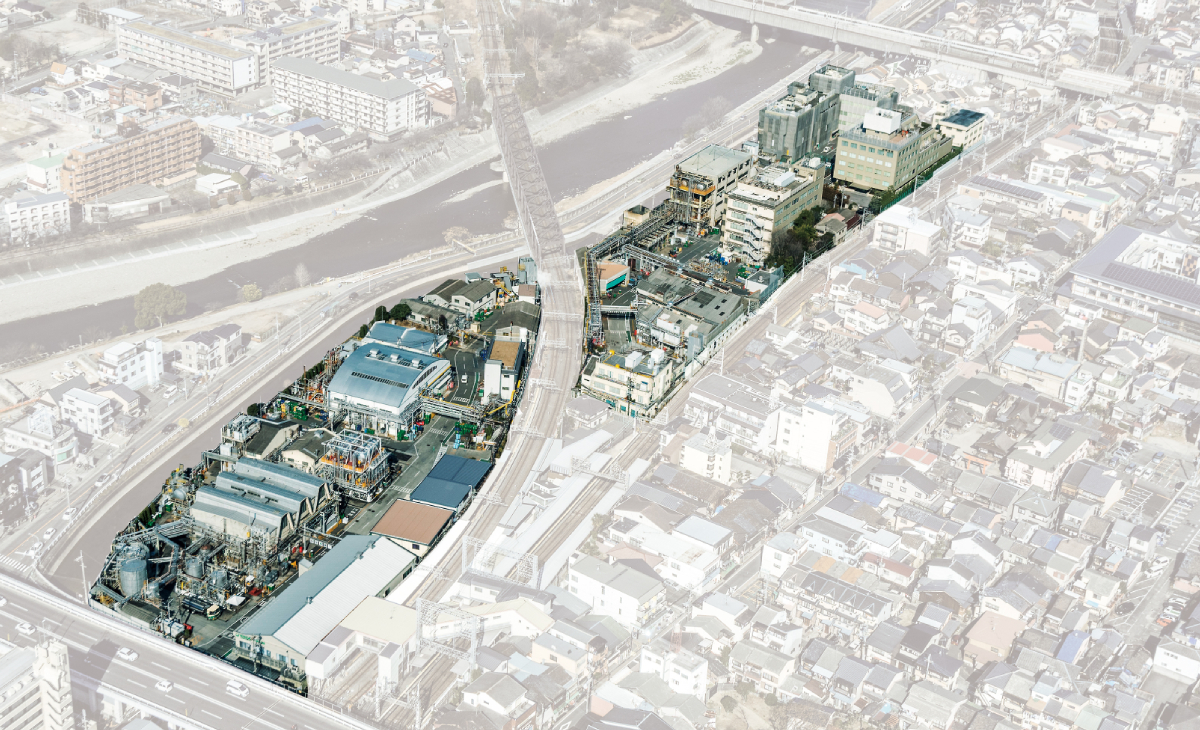

Kyoto Factory, Head Office, and Research Laboratory

The Kyoto Factory is Sanyo Chemical,s first production facility. Products manufactured at this factory include lubricant additives, coating-adhesive agents and surfactants.

Operation Date: 1949

Area: approx. 26,000 m2